A u-tube superheater

A U-shaped tube and superheater technology, applied in the field of boiler component structure, can solve problems such as maintenance, overall replacement difficulty, uneven flow, difficult manufacturing, etc., to prolong continuous operation time, reduce uneven flow, and reduce uneven heating average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

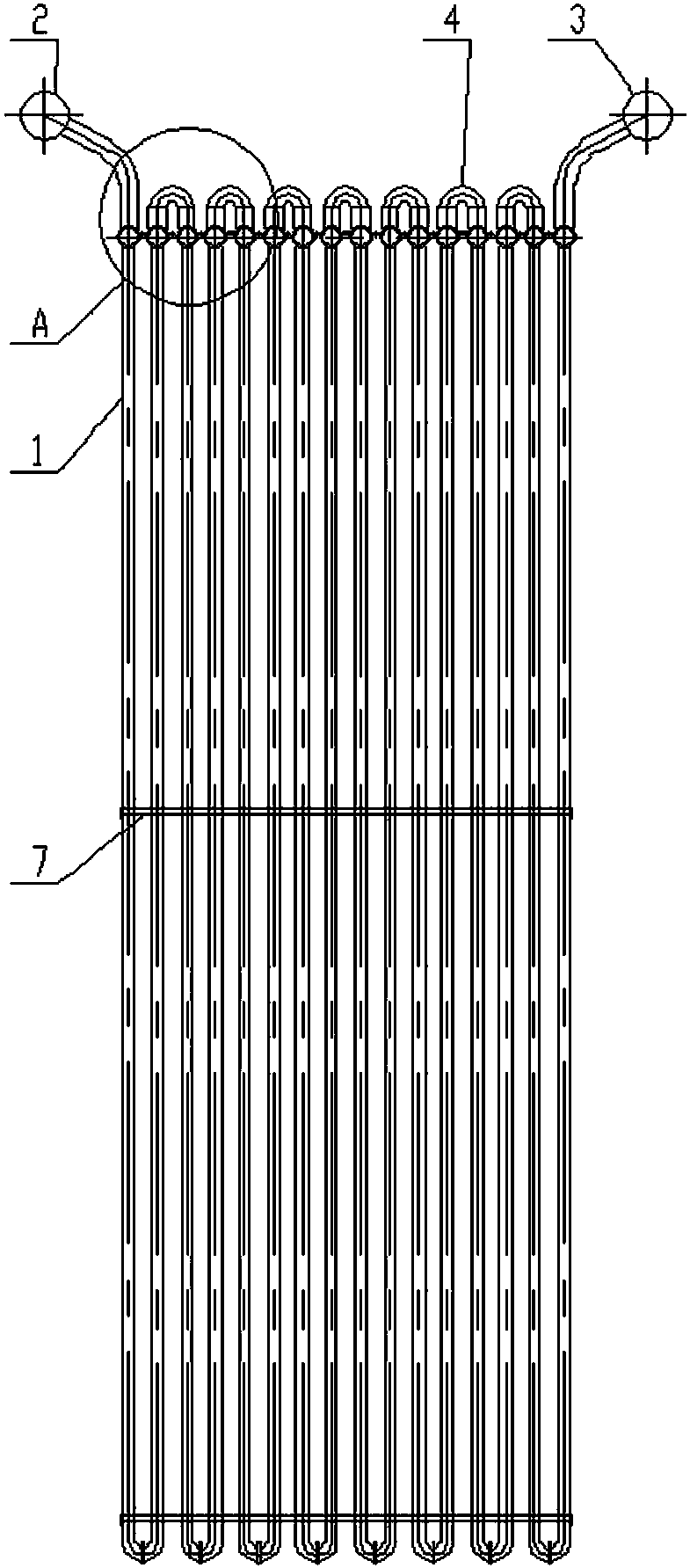

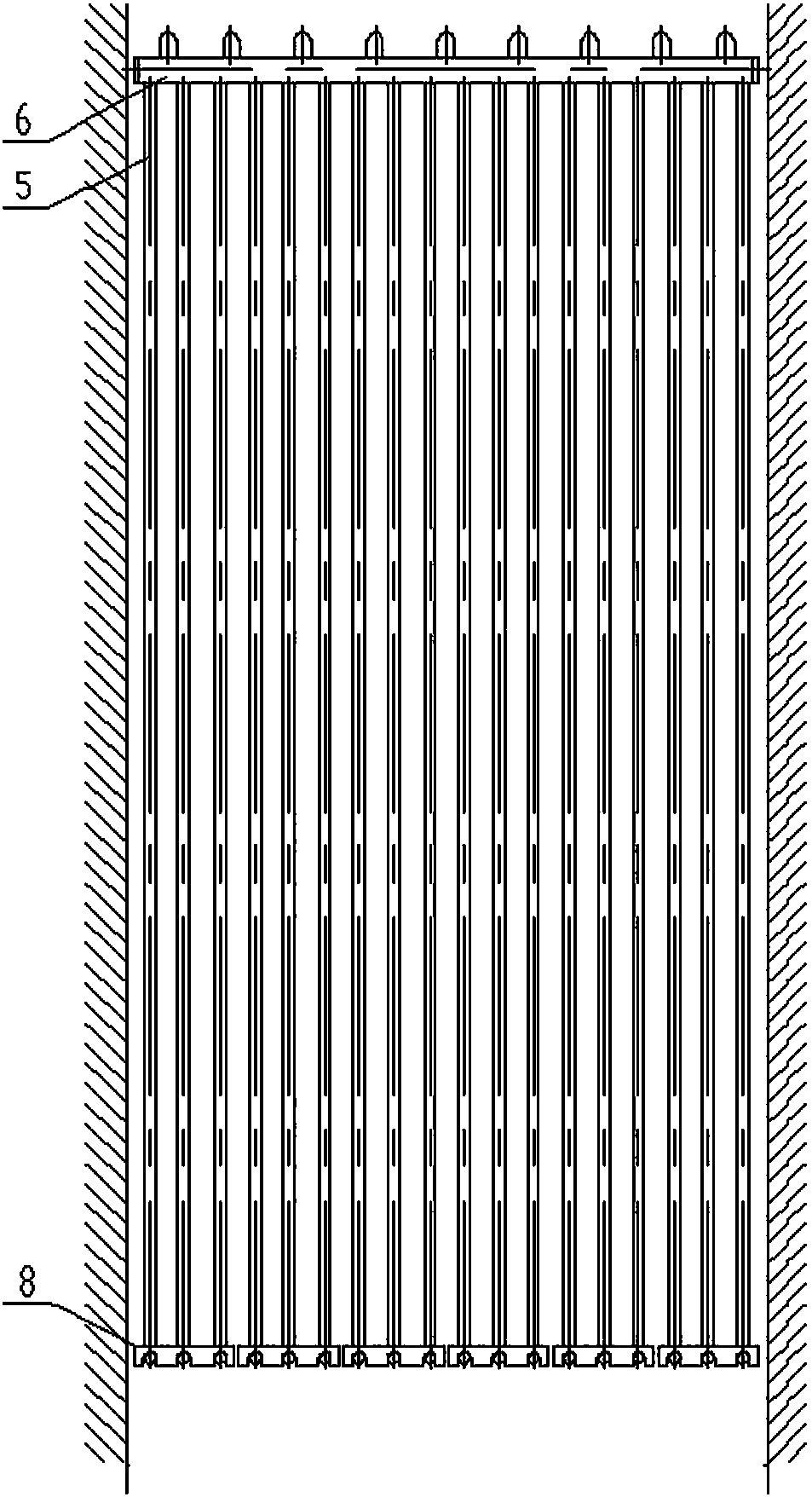

[0035] A U-shaped tube superheater is arranged in a horizontal flue. The U-shaped tube superheater of this embodiment adopts a single-tube coil U-shaped tube type.

[0036] A U-shaped tube superheater includes a superheater piping system 1 , an inlet header 2 and an outlet header 3 . The inlet header 2 and the outlet header 3 are respectively arranged at both ends of the superheater piping system 1 . The steam enters from the inlet header 2, exchanges heat with the flue gas through the superheater piping system 1, heats the saturated steam into superheated steam, and finally enters the outlet header 3.

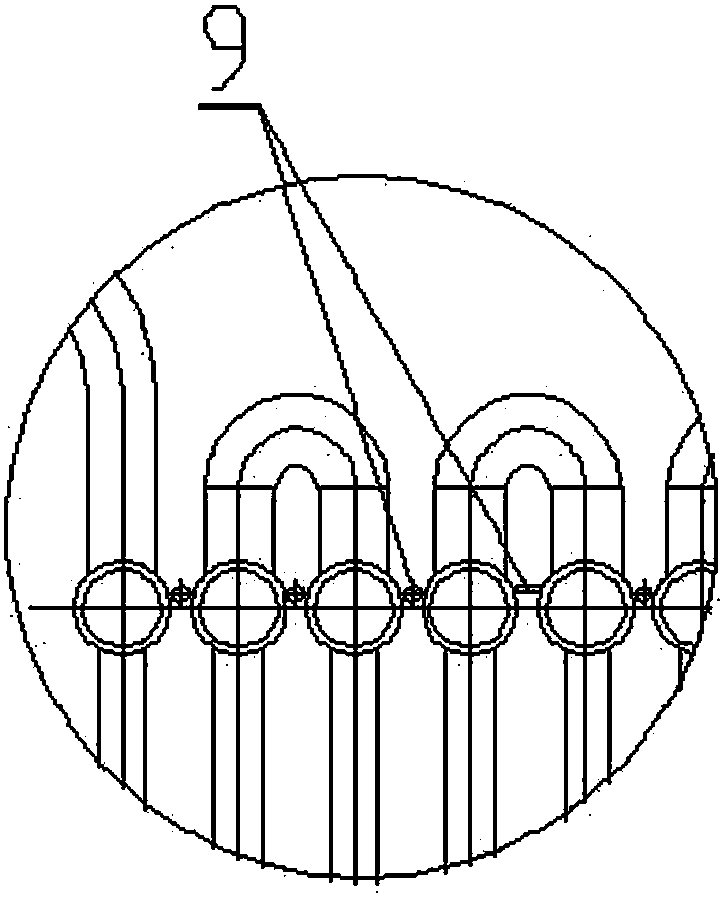

[0037] The superheater piping system 1 includes a U-shaped pipe 5 and a small header 6 .

[0038] The U-shaped pipe 5 is a U-shaped pipe with a single tube circle, which is U-shaped, and is vertically arranged in the horizontal flue. Preferably, the U-shaped tubes 5 are multiple, and the multiple U-shaped tubes 5 are evenly arranged horizontally and vertically, and the U-sha...

Embodiment 2

[0045] A U-shaped tube superheater is arranged in a horizontal flue, and the U-shaped tube superheater of this embodiment adopts a double-pipe coil U-shaped tube type.

[0046] The U-shaped pipe 5 is a U-shaped pipe with double pipe rings, which is U-shaped and includes an inner pipe ring and an outer pipe ring, and both ends of the inner pipe ring and the outer pipe ring are fixedly connected to the small header 6 .

[0047] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0048] The superheater pipe system of the present application adopts U-shaped pipes, which is beneficial to manufacture, installation and maintenance, and is also beneficial to the sealing of the flue. In order to meet the flue gas velocity in the flue and the steam velocity in the tube within the required range, the U-shaped tube superheater can adopt a single-tube U-shaped tube or a double-tube U-shaped tube according to the specific situat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com