Fluidized powder manifold quantitative distribution and stable injection system

A quantitative distribution and multi-branch technology, which is applied in the direction of block/powder supply/distribution, supply configuration, combustion method, etc., can solve the problems of increased injection pressure loss and energy loss, large distribution error, and difficult distribution accuracy, etc. , to achieve the effect of increasing adjustment means and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

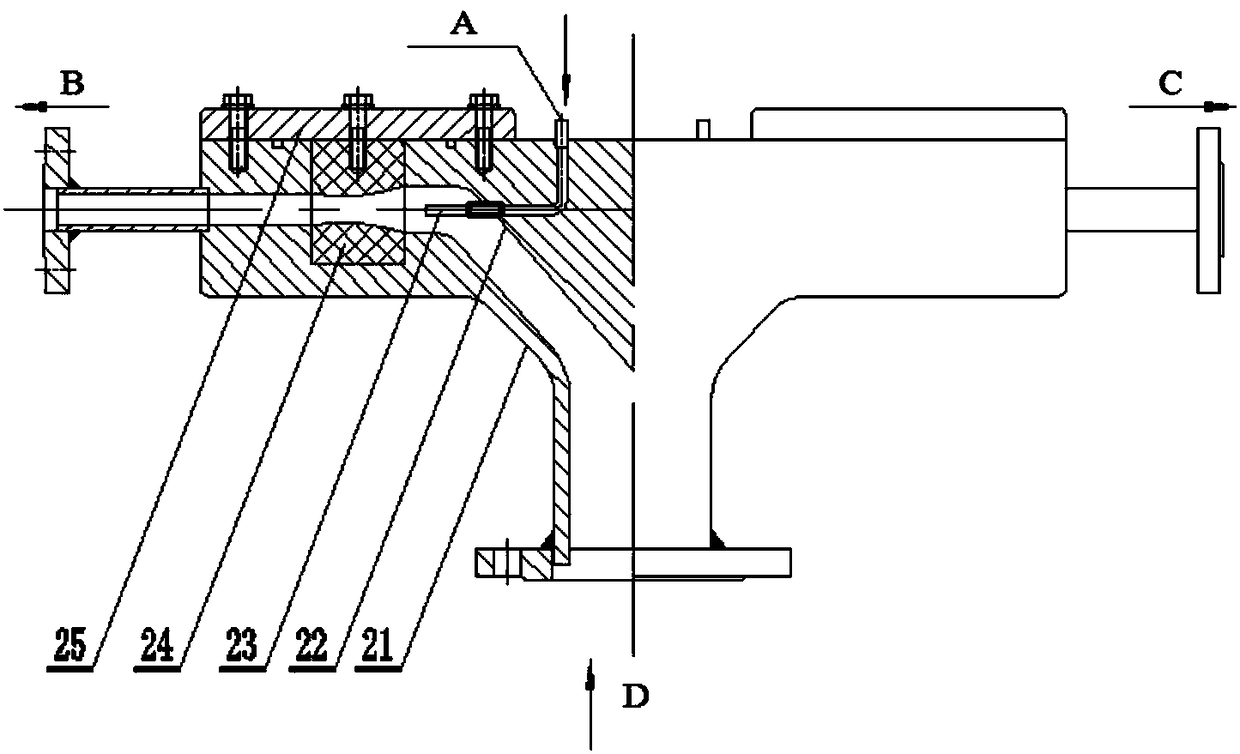

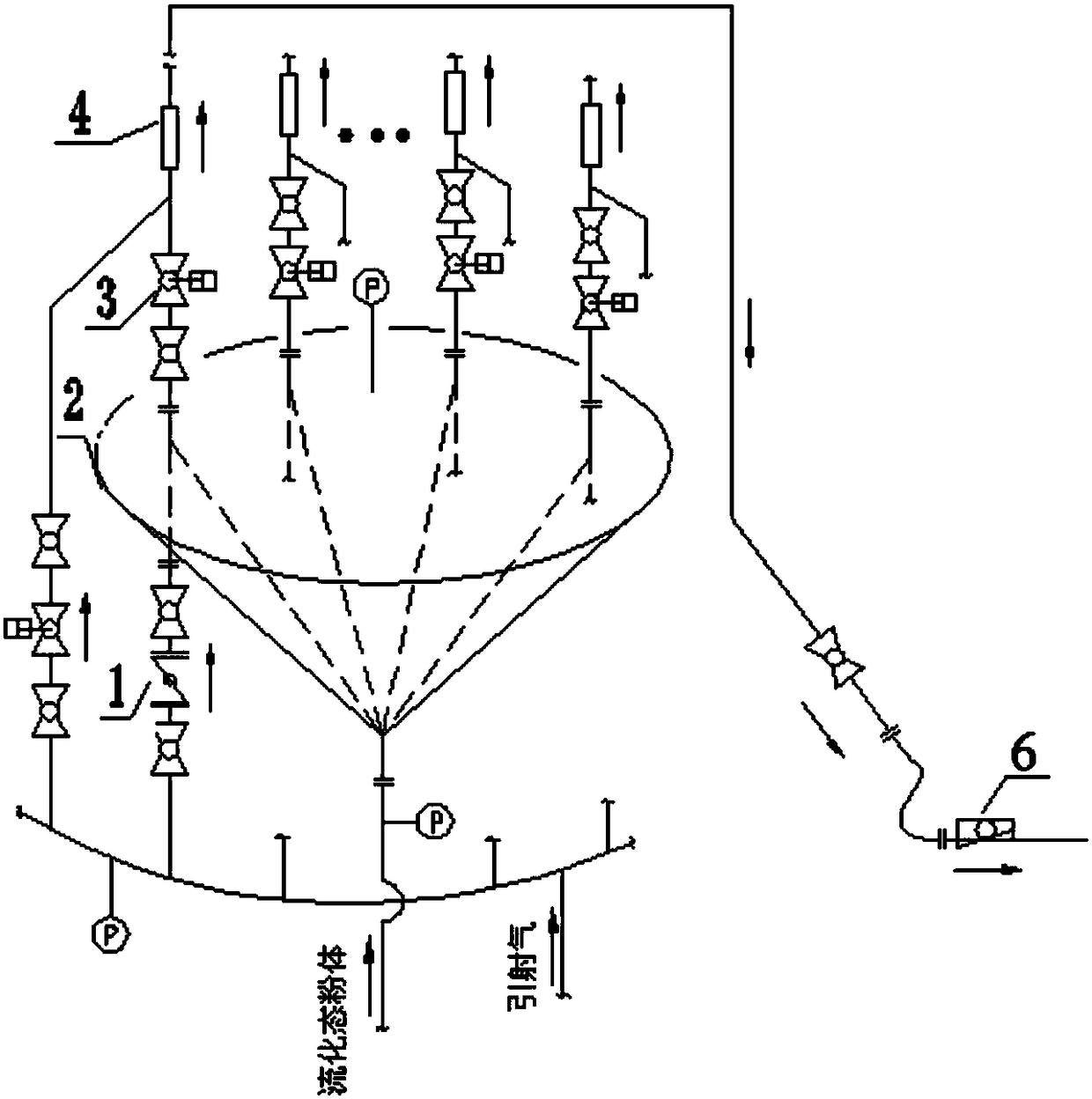

[0023] Such as Figure 1-2 As shown, the fluidized state powder manifold quantitative distribution and stable injection system of this embodiment includes a quantitative distribution mechanism 2; the quantitative distribution mechanism 2 includes a distribution body 21, a distribution cone 22 arranged in the distribution body 21, Several ejection gas nozzles 23 and several distribution rings 24 connected with the distribution cone 22;

[0024] The distribution body 21 includes a conical shell, a powder inlet communicating with the apex of the conical shell, and several powder outlets arranged along the circumferential direction on the side wall of the conical shell;

[0025] The bottom surface of the distribution cone 22 is connected to the top wall of the conical housing, the distribution cone 22 is coaxially arranged with the conical housing, and the conical surface of the distribution cone 22 is connected to the conical housing. The inner surface of the side wall is arrang...

Embodiment 2

[0031] On the basis of the above-mentioned embodiments, the quantitative distribution mechanism 2 also includes an injection branch pipe communicated with the injection gas nozzle 23 and a blowing branch pipe communicated with the powder outlet; the injection branch pipe is provided with A flow regulating valve 1, a branch blowing valve 3 and a branch flow meter 4 are sequentially arranged on the spray branch pipe along the powder flow direction.

[0032] By changing the ejection air flow rate, the powder flow rate entering each branch pipe can be controlled, so that the distribution of powder materials in each branch pipe is in a controllable and adjustable state, avoiding the "blind spray" phenomenon, due to the introduction of ejection air in the distribution device , which reduces the dependence of the uniformity index on the accuracy of the equipment during the injection process, cancels the equal-length design of the distribution branch pipe, and increases the adjustment ...

Embodiment 3

[0034] On the basis of the above embodiments, several ejection gas channels are arranged in the distribution cone 22, and the ejection gas nozzle 23 is connected to the ejection gas channels through threads. The injection gas nozzle 23 is made of wear-resistant material.

[0035] The nozzle 23 and the distribution cone 22 are connected by pipe threads. The distance from the nozzle 23 to the distribution ring 24 can be adjusted by adjusting the length of the threaded section screwed into the distribution cone 22. Effect of fluidized powder. The nozzle 23 is made of wear-resistant material, which can prolong the service life of the nozzle 23, and the threaded connection can quickly replace the nozzle 23, reducing the time for overhauling the quantitative distribution mechanism 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com