A method for putting into operation a w-flame once-through boiler into a dry burner

A once-through boiler and burner technology, which is applied in the direction of combustion methods, combustion with various fuels, combustion with block fuels and gaseous fuels, etc. It can solve the problem of reducing the life of the heating surface pipe material, starting time, and overheating of the central water-cooled wall pipe wall , single combination mode of operation and other problems, to achieve the effect of shortening the time to dry state, improving the service life of pipes, and flexible operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

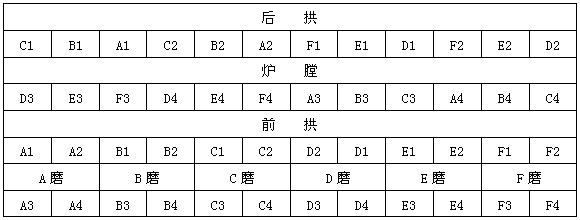

[0019] Embodiment 1: as Figure 1-Figure 4 As shown, a method for putting into operation a W-flame once-through boiler into a dry burner, including burners, the burners include a row of front and back arches, and each row is provided with twelve burners, and the front row of burners is sequentially arranged from left to right D3, E3, F3, D4, E4, F4, A3, B3, C3, A4, B4, C4, the rear burners are C1, B1, A1, C2, B2, A2, F1, E1 from left to right , D1, F2, E2, D4, and the two rows of burners are placed in sequence from left to right. The operation method includes: (1) The four burners A2, A3, F1, and F4 in the middle of the furnace width direction do not operate, effective Reduce the heat load of the heat-sensitive area of the central water-cooled wall; (2) Selectively cut off the burners B2, B3, E1 and E4 depending on the wall temperature of the water-cooled wall in the middle burner adjacent to the burner, that is, four burners B2 and B3 , E1 and E4 are put into operation, if...

Embodiment 2

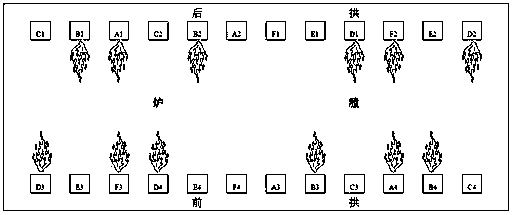

[0021] Example 2: For a W flame once-through boiler, before the boiler transition, B, D, A, F pulverized coal pulverization systems were put into operation, C, E pulverized coal pulverized systems could not be put into operation due to defects, A, F pulverized The operation of the burners of the coal pulverization system is as follows: A coal pulverization system is put into the burners A1 and A4 on both sides, and the middle A2 and A3 burners are not used; F coal pulverization system is put into the F2 and F3 burners on both sides. The F1 and F4 burners in the middle are not used, and the detailed layout of the burners is shown in figure 2 shown. When the burner is turned into a dry state according to the operation mode of the burner, the wall temperature of the heated surface of the water wall of the boiler is well controlled, the superheat degree of the boiler and the steam temperature have no large fluctuations, and the whole transition process is stable.

Embodiment 3

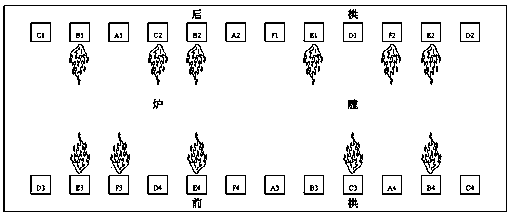

[0022] Example 3: For a certain W flame once-through boiler, B, C, E, F coal pulverization systems were put into operation before the boiler transitioned, D coal pulverization system could not be put into operation due to defects, F coal pulverization system The operation of the burner is as follows: F2 and F3 burners on both sides of the F coal pulverization system are put into operation, and the F1 and F4 burners in the middle are not used. Because the temperature of the water wall in the B3 burner area is high and the increase is fast, the adjacent B3 burns in the middle The burner is removed, and the detailed layout of the burner is shown in image 3 As shown, when the combination of burners in the pulverizing system is put into operation for transition, the wall temperature of the heated surface of the water wall of the boiler is well controlled, and the steam temperature and superheat are stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com