Conveying system for sintered ore

A conveying system and technology for sintered ore, applied in blast furnaces, lighting and heating equipment, furnace components, etc., can solve the problems affecting the low-temperature reduction and pulverization performance of sintered ore, uneven adhesion of sintered ore, inconvenient use, etc. Effect, simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

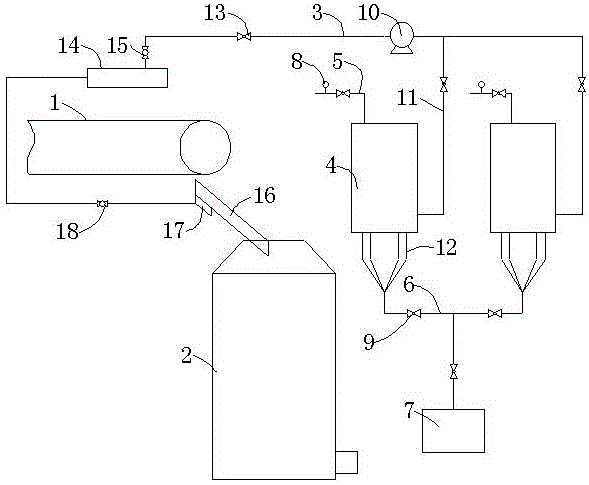

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] During specific implementation: if figure 1 As shown, a sinter conveying system includes a sinter conveying belt 1 and a halide solution spraying system capable of spraying the sinter on the sinter conveying belt 1, which is characterized in that it also includes a homogenizing silo 2. The inlet at the upper end of the homogenizing silo 2 is connected with the discharge end of the sinter conveyor belt 1, and the outlet of the homogenizing silo 2 is connected with the blast furnace.

[0033] In this way, a homogenizing silo is added in front of the blast furnace. After the sinter is sprayed with halide by the halide solution (calcium chloride solution is used in this embodiment) spray system, since the sinter itself still has a certain temperature, the Sending into the homogenization silo to stay for a period of time can make the sprayed halide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com