Gas-fluid sealing detection apparatus

A technology of sealing detection and gas-liquid, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the instability of manual detection, detection accuracy, frequent cleaning of the detection site, and easy Contaminate the tested product and other problems, achieve the effect of simple and reasonable structure, clean and tidy testing environment, and reduce investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

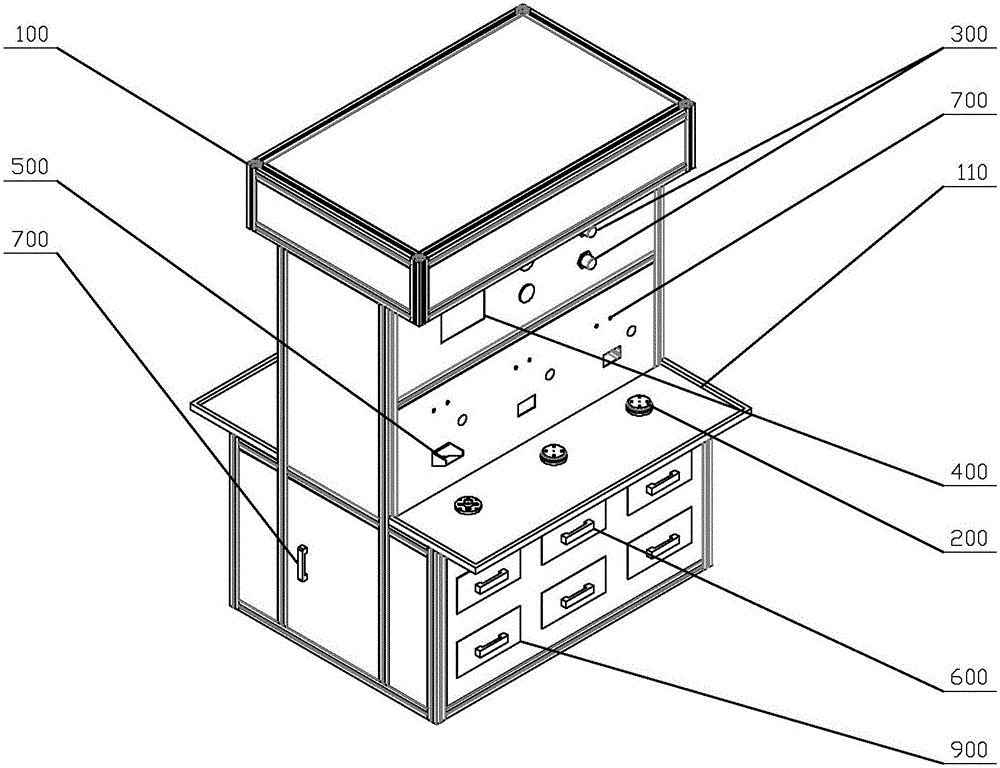

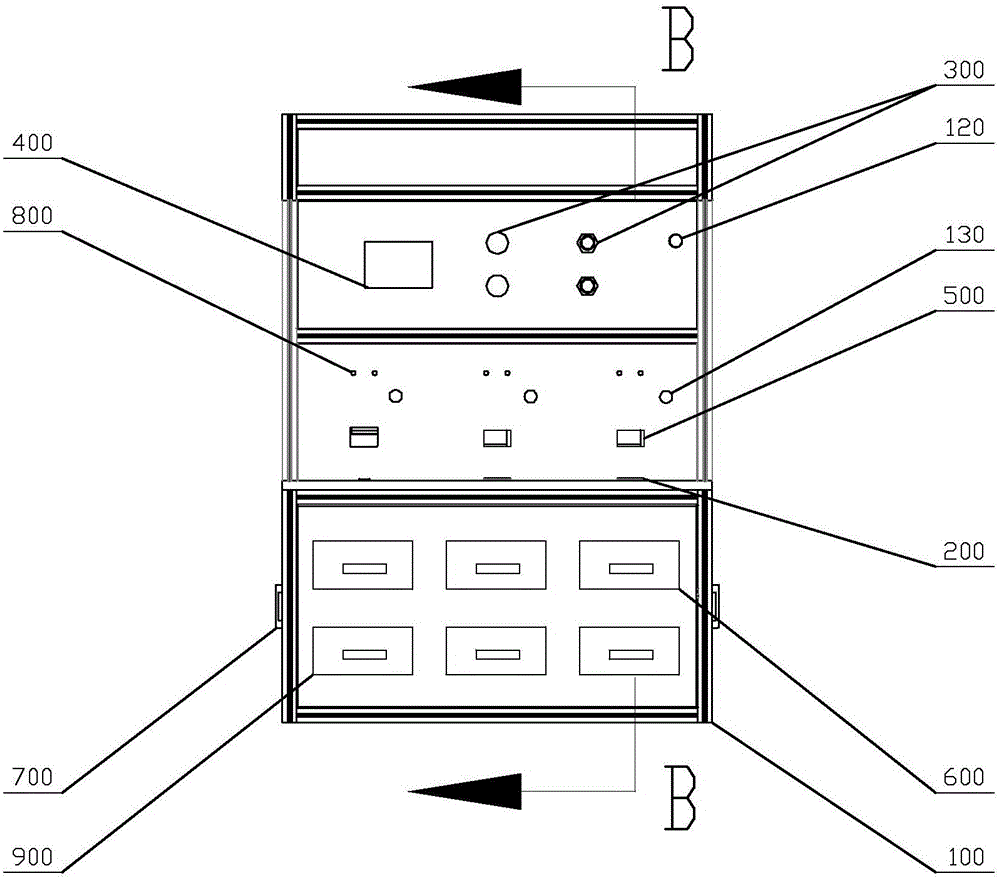

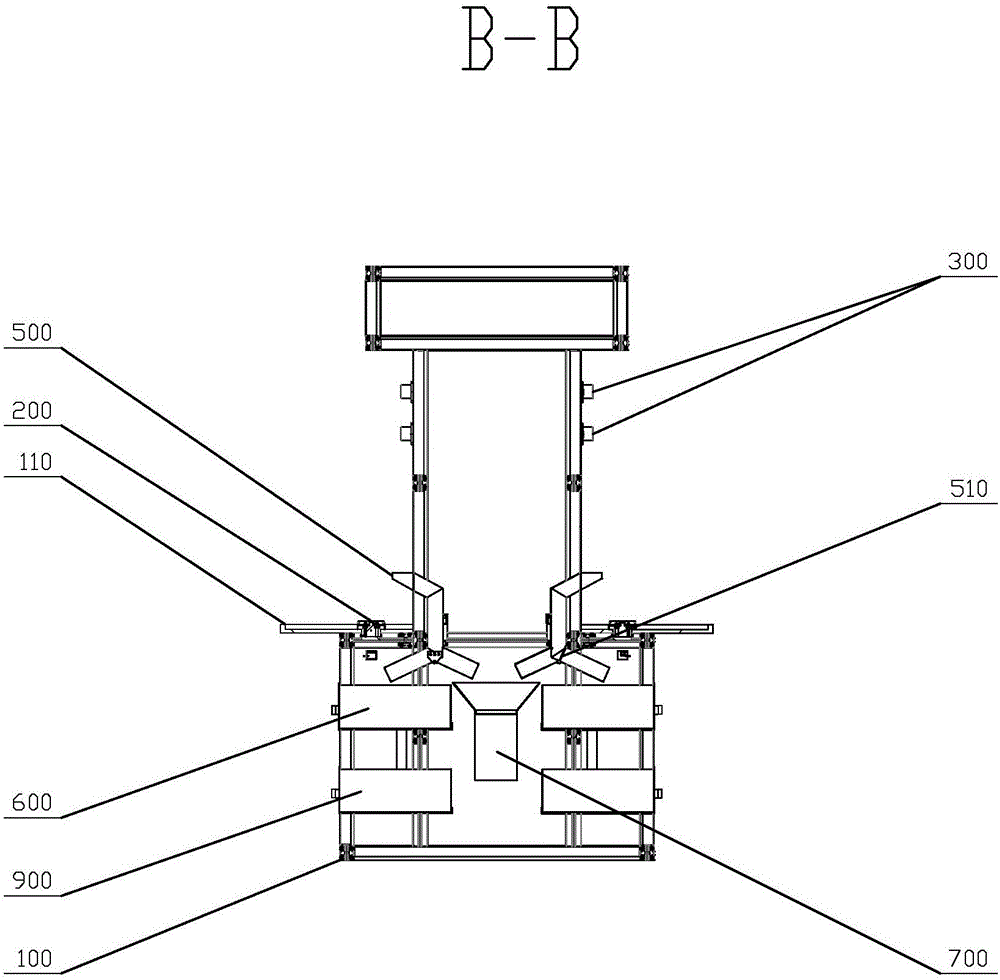

[0031] like Figure 1 to Figure 3 As shown, a gas-liquid sealing detection device includes a frame 100, a detection mechanism 200, a pressure display adjustment mechanism 300, a display control mechanism 400, a sorting mechanism 500, a discharge area 600 for qualified products, and a discharge area for unqualified products 700 , the status indicating mechanism 800 and the tool box 900 .

[0032]The frame 100 is provided with a detection mechanism 200, a pressure display adjustment mechanism 300, a display control mechanism 400, a sorting mechanism 500, a qualified product discharge area 600, a non-conforming product discharge area 700, a status indicating mechanism 800 and a toolbox. 900; the frame 100 is vertically provided with a pressure display adjustment mechanism 300, a display control mechanism 400, a sorting mechanism 500, and a status indicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com