Horizontal type current-carrying friction arc tester

A current-carrying friction, testing machine technology, applied in the direction of testing wear resistance, etc., can solve the problems of affecting arc performance, inconvenient interception of disk sample quality, and unfavorable ablation mechanism research, and achieve the effect of convenient clamping and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

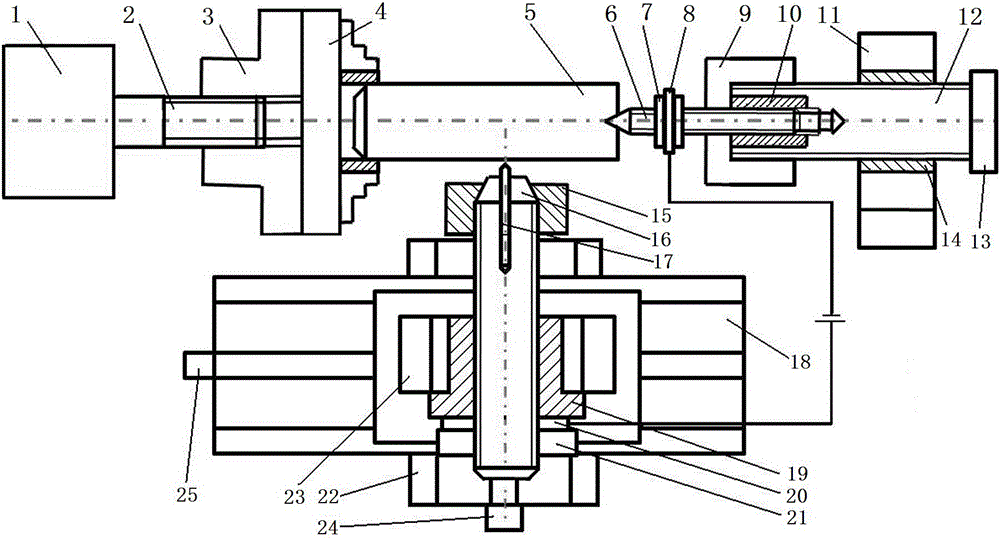

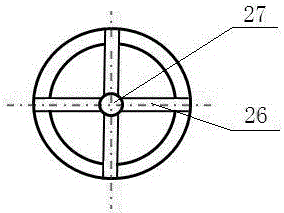

[0019] like figure 1 and figure 2 As shown, a horizontal current-carrying friction arc testing machine includes a sample clamping drive device, a two-way mobile stage and a current loading device. The sample clamping drive device is used to drive a cylindrical sample 5 around it. Its own central axis rotates, and a sample driving motor 1 is installed in the sample clamping drive device. The output shaft of the sample driving motor 1 is fixedly connected to the main shaft 2, and the main shaft 2 is provided with a clamp for fixing the three-jaw chuck 4. The flange 3 and one end of the cylindrical sample 5 are clamped in the three-jaw chuck 4 and rotate together with it, and the claws of the three-jaw chuck 4 and the cylindrical sample 5 are electrically isolated by an insulating sleeve.

[0020] The two-way mobile stage can realize simultaneous movement along the axial direction of the cylindrical sample 5 and the axial direction perpendicular to the cylindrical sample 5, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com