Method and device for testing small strain viscoelastic parameters of geotechnical engineering materials by bending element

A technology of geotechnical engineering and elastic parameters, applied in the analysis of materials, the analysis of solids using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of lack of a unified, simple and reliable method, unclear boundary conditions of the self-vibrating column test, etc. Achieve the effect of saving test time, eliminating uncontrollable effects, and eliminating test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

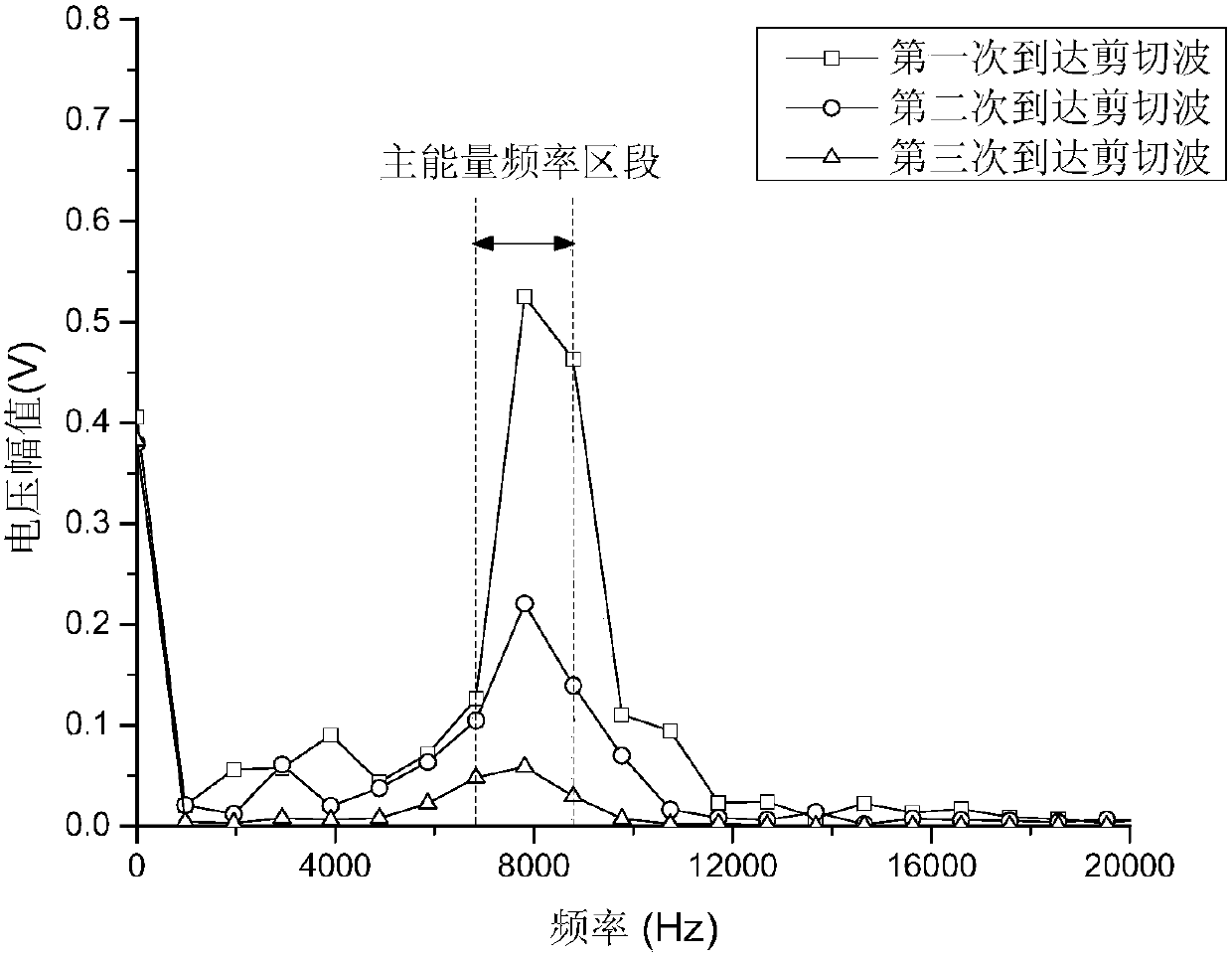

[0046] The method is based on a bending element testing device, and the viscoelastic index of the test material is obtained by analyzing the body wave velocity and body wave attenuation.

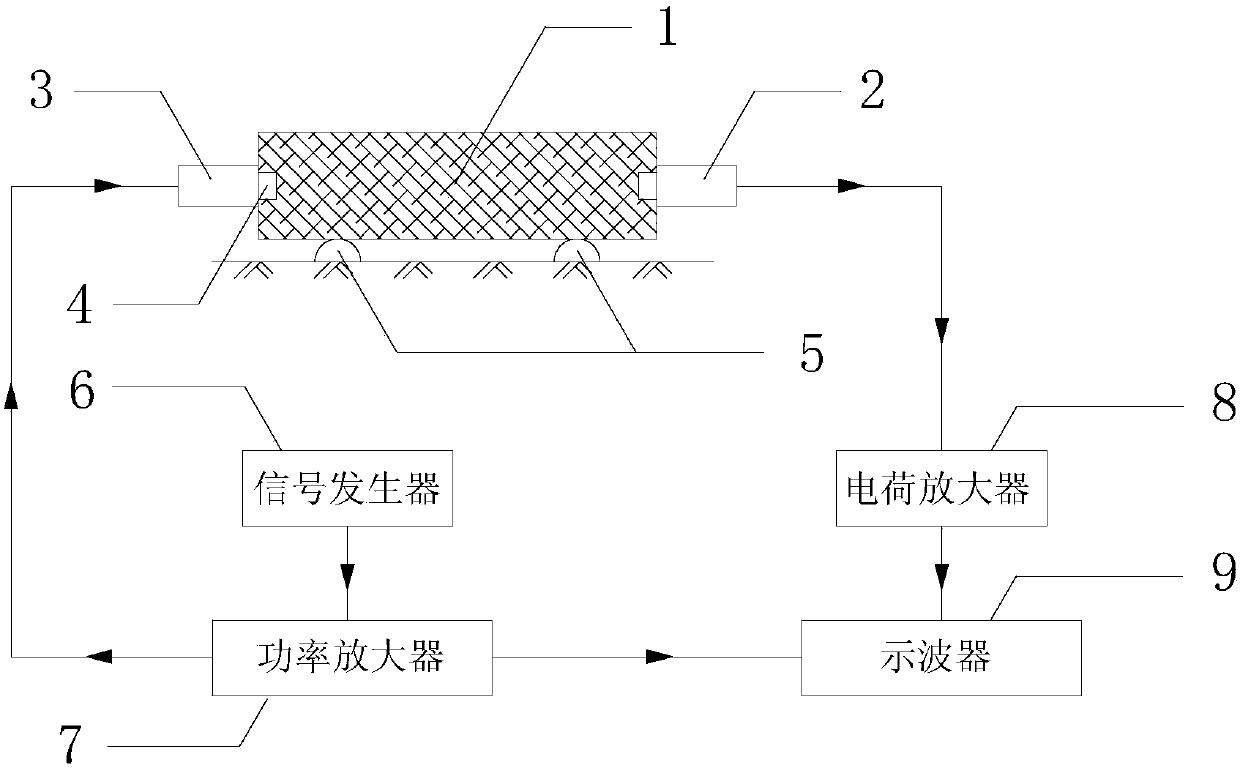

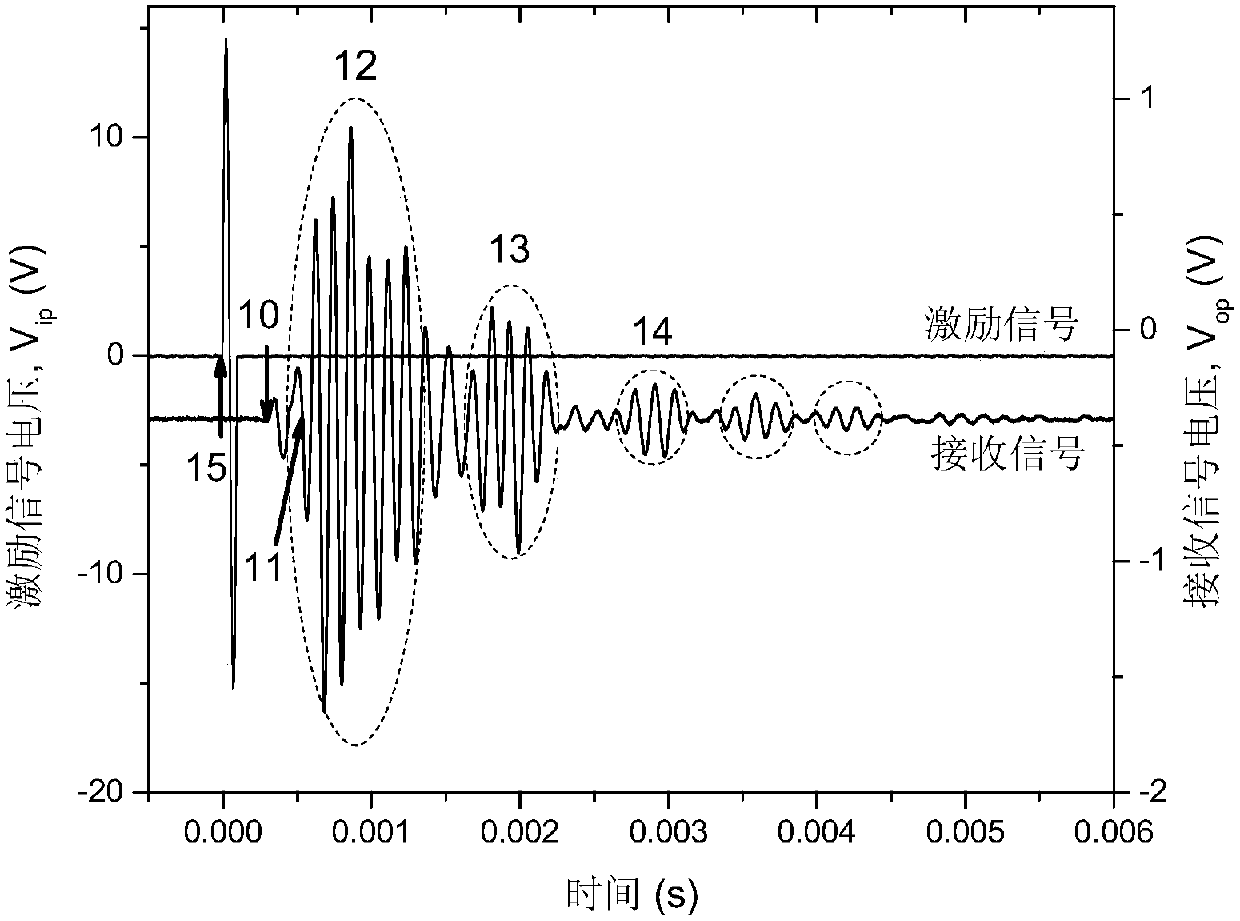

[0047] The test device of this method includes a receiving bending unit 2, an exciting bending unit 3, a foam rod 5, a signal generator 6, a power amplifier 7, a charge amplifier 8 and an oscilloscope 9. The test needs to prepare a cylindrical sample with a relatively large length and diameter, and use Place as little contact area as possible on the foam rod 5, and the fulcrum position is 0.2L indented at both ends of the sample. During the test, the bending element at one end of the sample excites a pulse signal, which includes compression wave and shear wave components, which are recorded by the receiving bending element at the other end after pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com