Mainboard automatic picking and placing device and method and FCT device

An automatic pick-and-place, motherboard technology, used in measuring devices, electronic circuit testing, instruments, etc., can solve the problems of low test efficiency, low degree of automation, large manpower, etc., to improve the test efficiency and degree of automation, improve the degree of automation, Realize the effect of unmanned work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

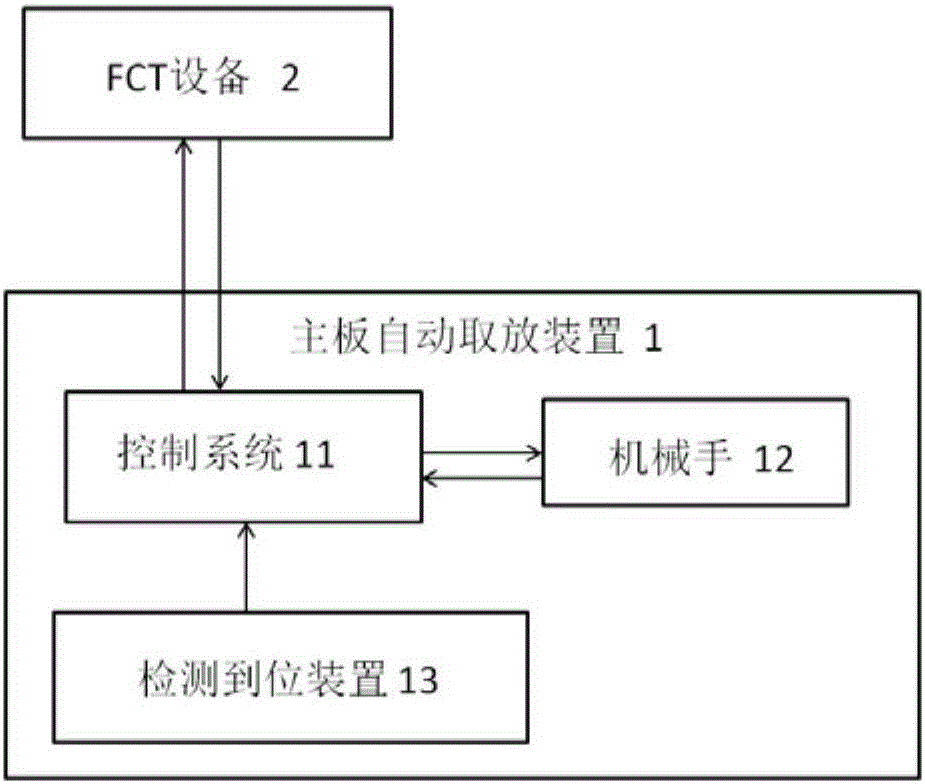

[0054]This embodiment provides an automatic pick-and-place device for a mainboard. The automatic pick-and-place device for a mainboard is mainly used on an FCT device, and is linked with the FCT device to realize automatic pick-and-place of a mainboard on the FCT device. Specifically, such as figure 1 As shown, the automatic pick-and-place device 1 in the present embodiment includes a control system 11 and a manipulator 12 (wherein, the structure diagram of the manipulator 12 is shown in Figure 2 to Figure 7 shown). Wherein, the control system 11 is connected with the manipulator 12 for controlling the manipulator 12 to pick and place the main board. Wherein, the control system 11 is used to connect the FCT equipment 2, so that the mainboard automatic pick-and-place device 1 in this embodiment is linked with the FCT equipment 2; specifically, when the manipulator 12 puts the mainboard on the test bench of the FCT equipment 2, the control System 11 sends a starting test sign...

Embodiment 2

[0058] Preferably, this embodiment provides a motherboard automatic pick-and-place device, compared with the previous embodiment, such as figure 1 As shown, the mainboard automatic pick-and-place device 1 in this embodiment also includes a position detection device 13 . Wherein, the position detection device 13 is used to be placed on the test post of the main board production line to detect whether the main board has reached the designated position on the test post. Wherein, the detection device 13 is connected with the control system 11, when the main board arrives at the designated position on the test post, the detection device 13 sends a signal in place to the control system 11, and the control system 11 judges whether to pick and place the main board according to the received signal; If so, the control system controls the manipulator 12 to pick and place the main board on the test platform of the FCT equipment 2 .

[0059] For example: when there is no test board on the...

Embodiment 3

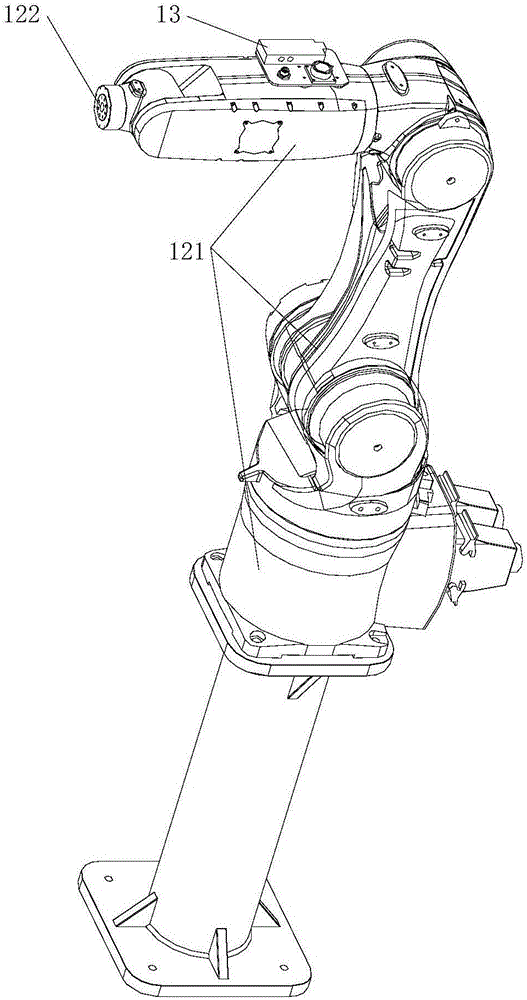

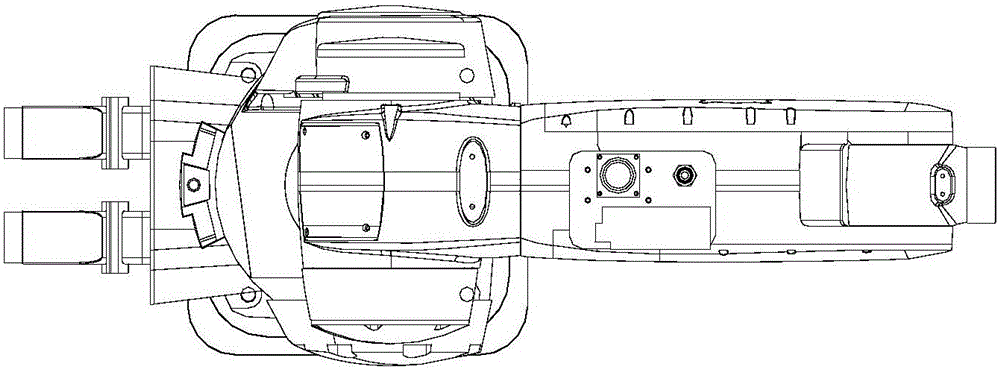

[0063] Preferably, this embodiment provides a motherboard automatic pick-and-place device, compared with the above-mentioned embodiment, such as Figure 2 to Figure 7 As shown, the manipulator in this embodiment includes a motion mechanism 121 and a pick-and-place mechanism 122 . Wherein, the control system of the main board automatic pick-and-place device is connected with the motion mechanism 121 for controlling the running track of the motion mechanism 121 . The pick-and-place mechanism 122 is connected with the kinematic mechanism 121 and the control system respectively, and the kinematic mechanism 121 is used to make the pick-and-place mechanism 122 or the main board arrive at a set position (as, make the pick-and-place mechanism 122 arrive at the position where the main board is located, or make the take-and-place mechanism 122 that carries the main board reach the set position. Placement mechanism 122 arrives at the FCT equipment test bench, or makes the pick-and-place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com