Cleaning method for quartz devices used by diffusion process in manufacturing of photovoltaic cell

A photovoltaic cell and quartz technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as pollution, affecting product quality and conversion efficiency, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

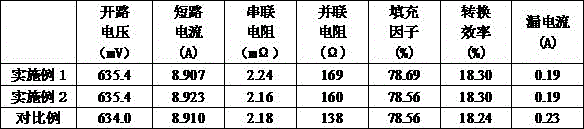

Embodiment 1

[0020] A cleaning method for quartz devices used in the diffusion process of photovoltaic cell manufacturing. The specific implementation steps are as follows:

[0021] (1) Cleaning the tank: Take out the debris and other sundries in the tank, rinse the tank with pure water for 5 minutes, and drain the flushing water to keep the tank tidy;

[0022] (2) Put the quartz device: slowly put the quartz device into the tank;

[0023] (3) Inject pure water: inject pure water into the tank body, the volume of pure water is 1 / 6 of the tank body volume, to prevent acid splashing when preparing acid solution;

[0024] (4) Prepare the solution: prepare the solution according to the volume ratio of HF:HCl:pure water at 2:1:25, carefully and slowly pour the chemicals into the tank to prevent the liquid from splashing;

[0025] (5) Bubbling: time is 5min;

[0026] (6) Pickling: Acid soaking for 3h;

[0027] (7) Washing: The washing time is 30min;

[0028] (8) Flushing: flush with pure water gun;

[0029] (...

Embodiment 2

[0032] A cleaning method for quartz devices used in the diffusion process of photovoltaic cell manufacturing. The specific implementation steps are as follows:

[0033] (1) Cleaning the tank: Take out the debris and other sundries in the tank, rinse the tank with pure water for 8 minutes, and drain the flushing water to keep the tank tidy;

[0034] (2) Put the quartz device: slowly put the quartz device into the tank;

[0035] (3) Inject pure water and prepare the solution: inject pure water into the tank, the volume of the pure water is 1 / 8 of the tank volume, to prevent the acid from splashing when preparing the acid;

[0036] (4) Prepare the solution: prepare the solution according to the volume ratio of HF:HCl:pure water at 3:2:25, carefully and slowly pour the chemicals into the tank to prevent the liquid from splashing;

[0037] (5) Bubbling: the time is 8min;

[0038] (6) Pickling: acid soaking for 4h;

[0039] (7) Washing: The washing time is 20min;

[0040] (8) Flushing: flush wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com