An alkaline dry battery electrolyte centrifugal absorption device

An absorption device and electrolyte technology, which is applied in the manufacture of primary battery equipment, battery pack components, circuits, etc., can solve the problems of high electrolyte absorption efficiency, insufficient electrolyte absorption, etc., and achieve not easy deterioration and good absorption effect. , to achieve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

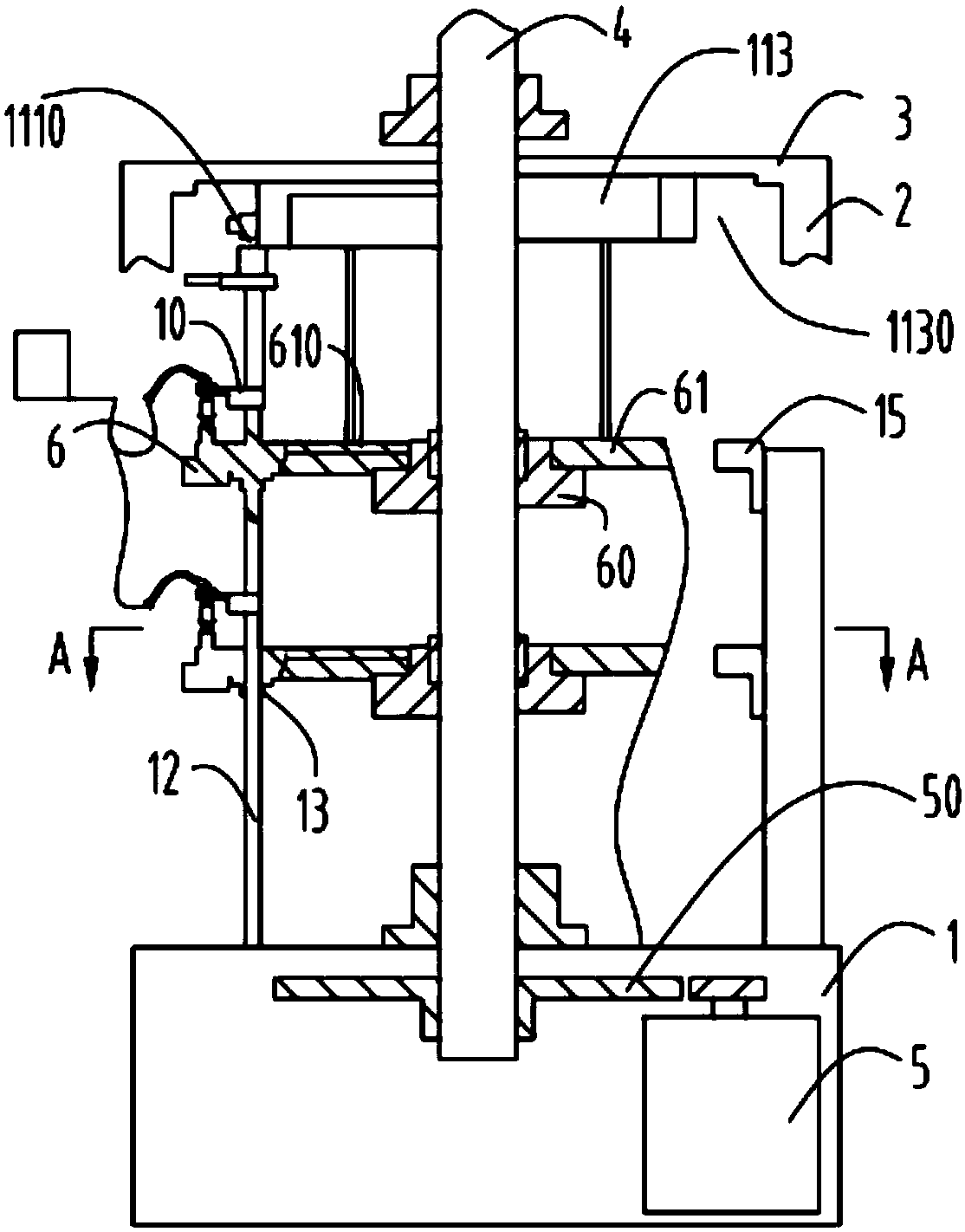

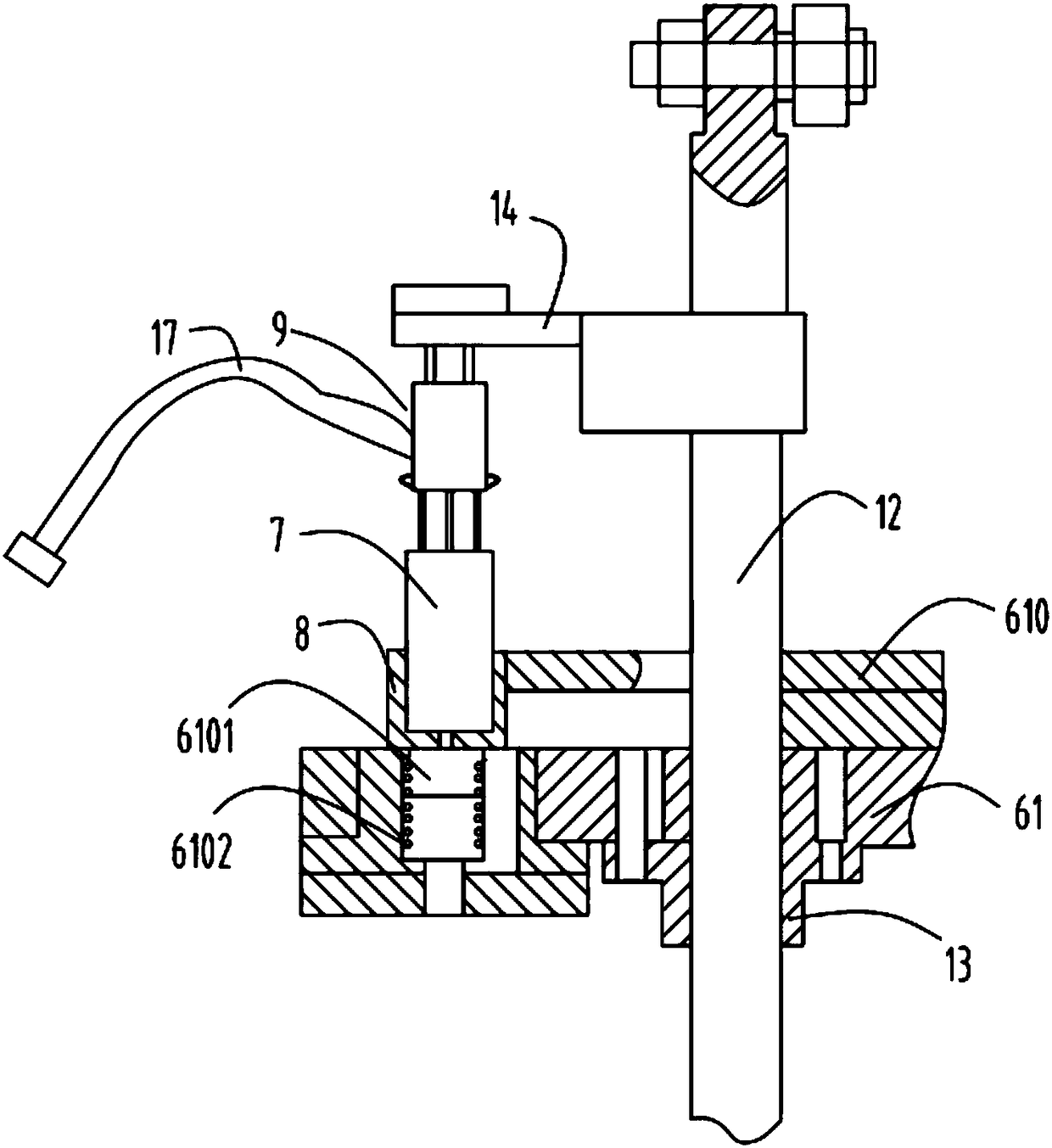

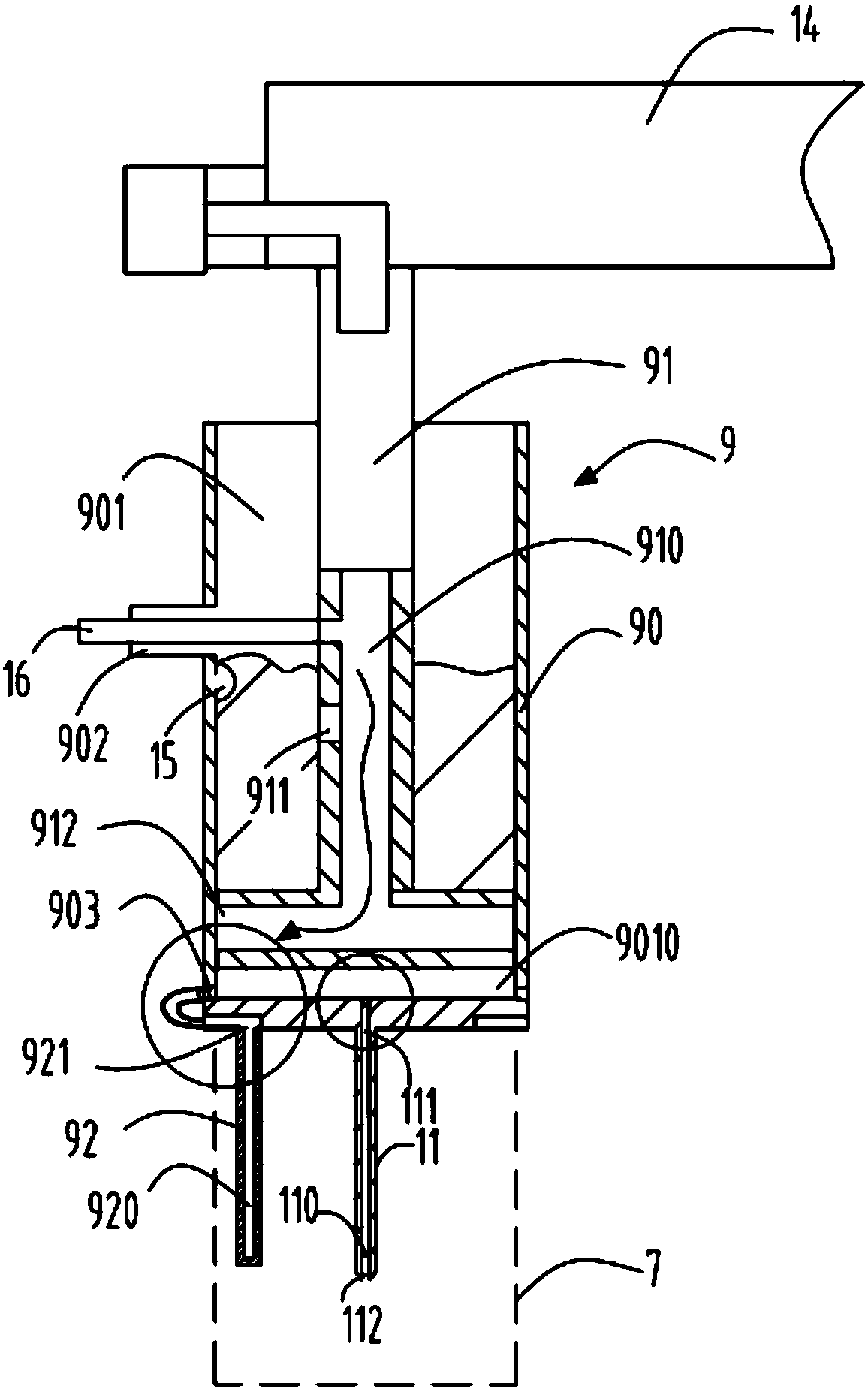

[0036] like figure 1 and figure 2As shown, an alkaline dry battery electrolyte centrifugal absorption device includes a base 1, a column 2 fixed to the base, a top plate 3 fixedly arranged on the top of the column, and a drive shaft 4 installed vertically on the base 1 and the top plate 3, The driving shaft 4 is powered by a gear 50 driven by the driving motor 5, and the driving shaft 4 is provided with a cup rotating mechanism 6, and the cup rotating mechanism 6 is evenly distributed along the circumferential direction with a plurality of cups 8 for installing batteries 7 It also includes an injection mechanism 9, which is used to inject the electrolyte into the battery 7; a lifting mechanism 10 that drives the injection mechanism 9 to move up and down, and the lifting mechanism 10 includes a first The cam 113 is provided with a cam spiral groove 1130 on the circumferential surface of the first cam 113, and the cam spiral groove 1130 is slidably connected with bearing conne...

Embodiment 2

[0060] In this embodiment, the number of the centrifugal guns 92 is two, the bottom plate 903 is provided with a groove 9030 for the centrifugal guns 92 to rotate and move, and also includes a centrifugal gun connecting rod 923 connecting the centrifugal guns 92 as a whole, The centrifugal gun connecting rod 923 is connected with a motor 924 , and the motor 924 drives the centrifugal gun 92 to move along the rotation movement slot 9040 . Except for this, other structures, positions and connections are the same as those in Embodiment 1.

[0061] During the working process, the electrolyte is thrown out under the action of centrifugal force to realize the injection of the electrolyte. The two centrifugal guns 92 rotate in the same direction through a motor 924. Centrifugation can realize the full throwing of the motor fluid, and realize dynamic spraying, which is beneficial to the absorption of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com