High torque low loss permanent magnet fault tolerant motor

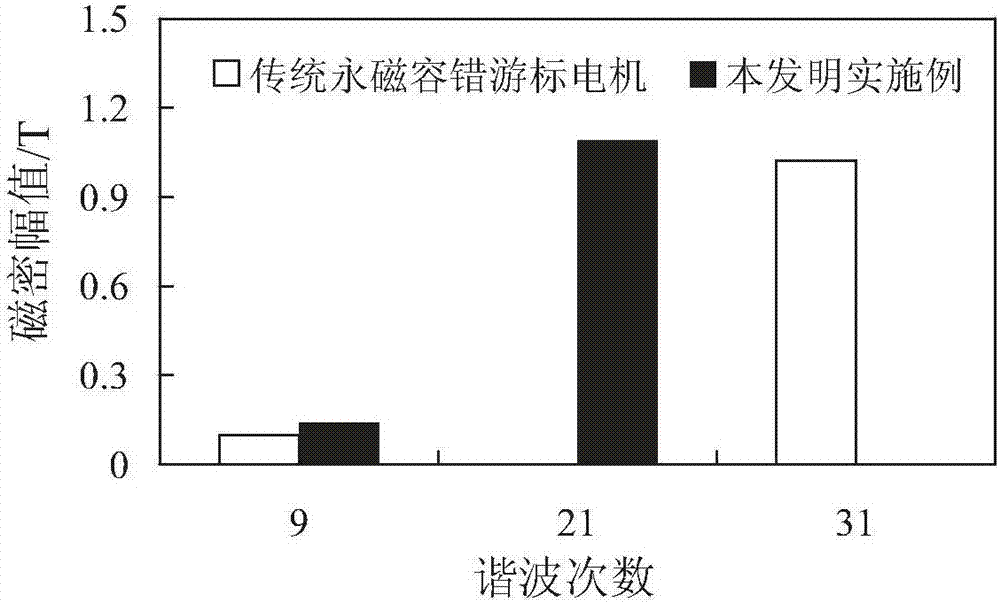

A permanent magnet fault-tolerant, permanent magnet technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems that have not been fundamentally solved, increase the magnetic flux leakage between the permanent magnet poles, and increase the magnetic flux leakage between the permanent magnet poles. , to achieve the effect of enhancing independence, suppressing magnetic flux leakage between poles, and reducing core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

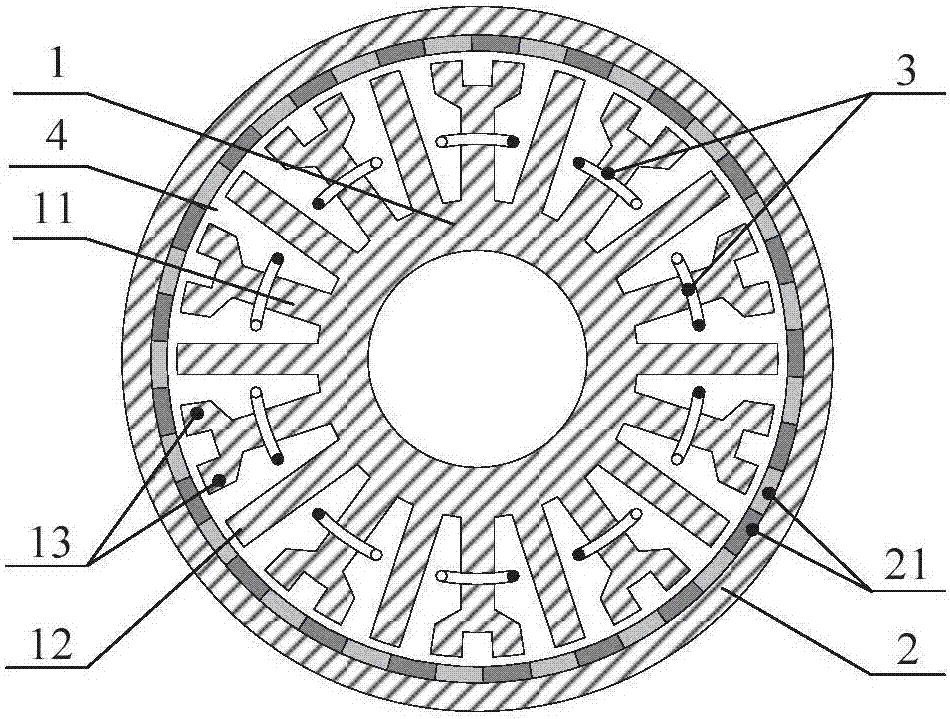

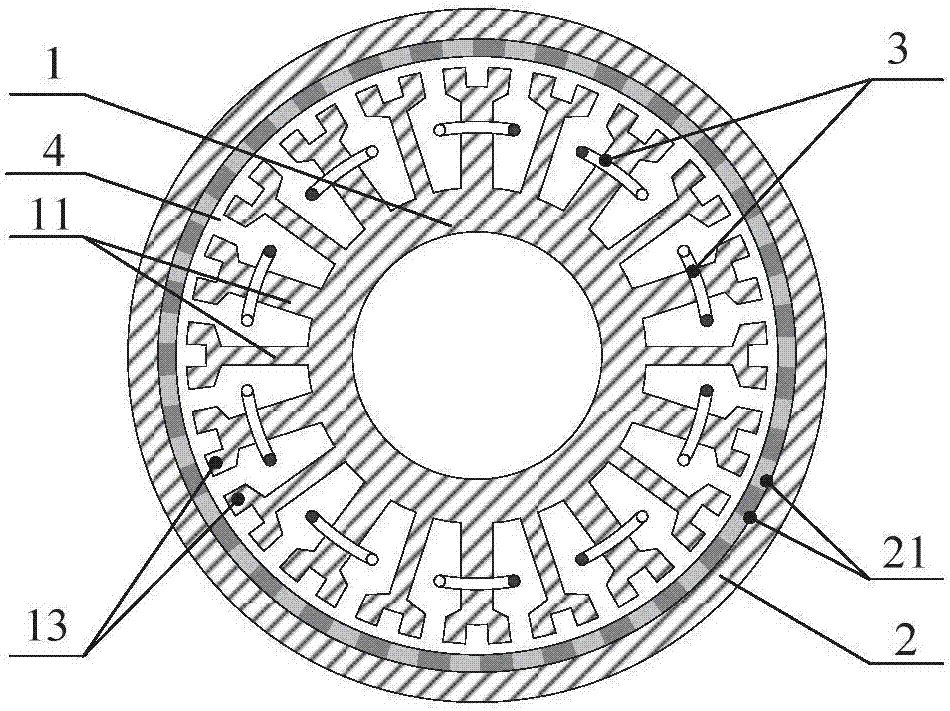

[0024] The structural features and beneficial effects of the motor of the present invention will be described in detail below using a specific five-phase motor with reference to the accompanying drawings.

[0025] Such as figure 1 As shown, the present invention discloses a stator permanent magnet fault-tolerant vernier motor, including a hybrid stator 1 and a rotor 2, and an air gap is arranged between the hybrid stator 1 and the rotor 2; the hybrid stator 1 includes two stators of different structural types arranged alternately The teeth are stator teeth 11 with small slots at the tooth ends and stator teeth 12 without small slots at the tooth ends. The tooth bodies of the two are parallel teeth, which extend vertically to the yoke of the stator and are connected with the yoke of the stator to form a whole , the end of the stator tooth 11 with a small slot at the tooth end has one or more small slots, forming a plurality of first modulation poles 13, and the end of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com