Reluctance type wheel hub motor

A wheel hub motor and reluctance technology, applied in the field of electric vehicles, can solve the problems of low output efficiency of the motor matching square wave controller, narrow range of high motor efficiency, and small space for speed regulation, etc., to achieve high-efficiency debugging, broaden the scope of application, High-speed and high-efficiency output characteristics, the effect of increasing the cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

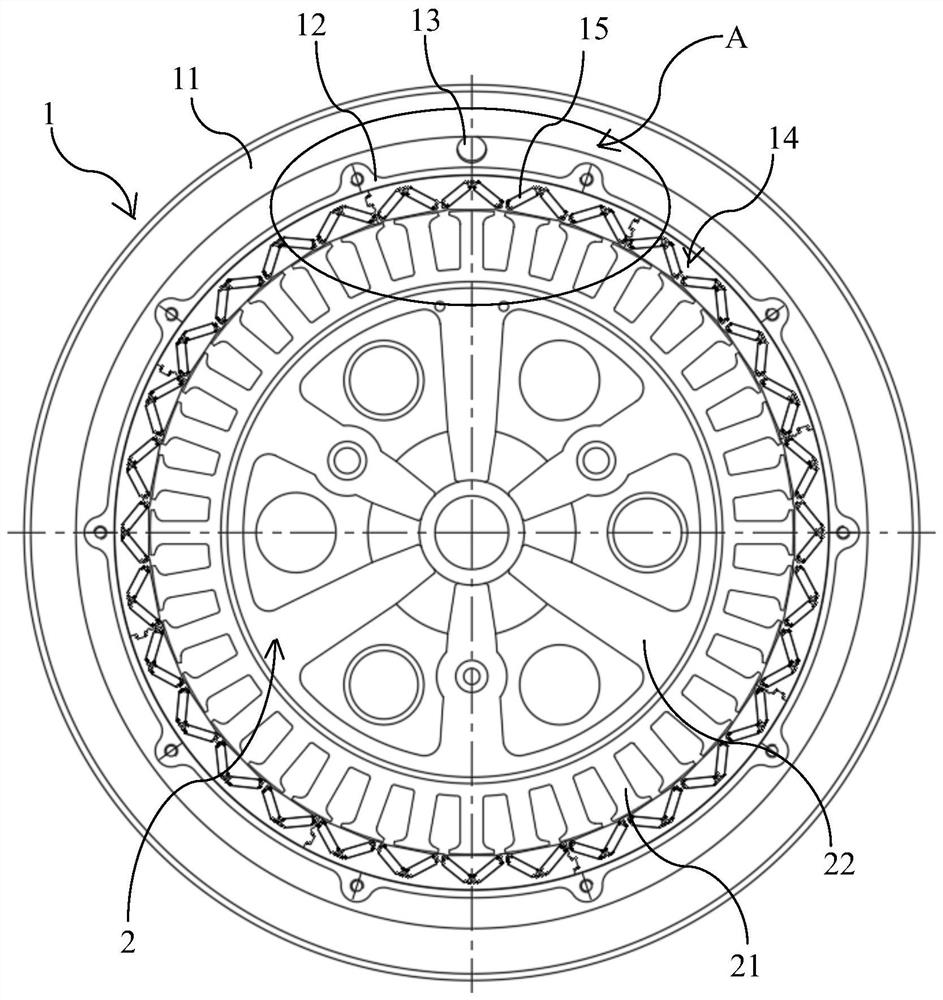

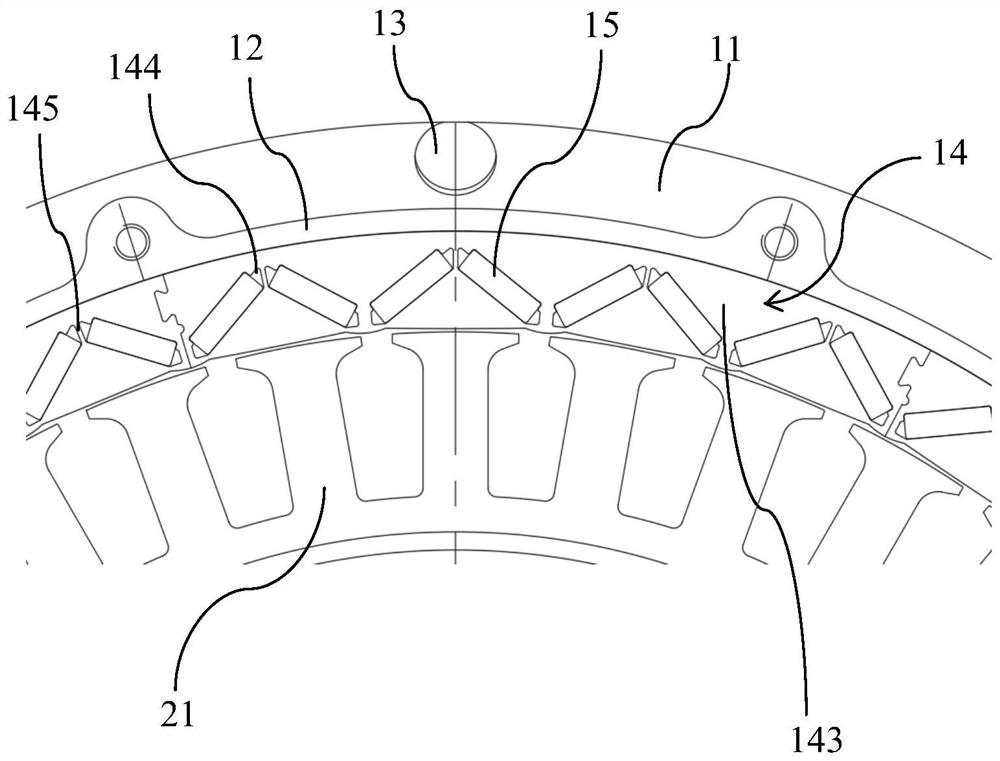

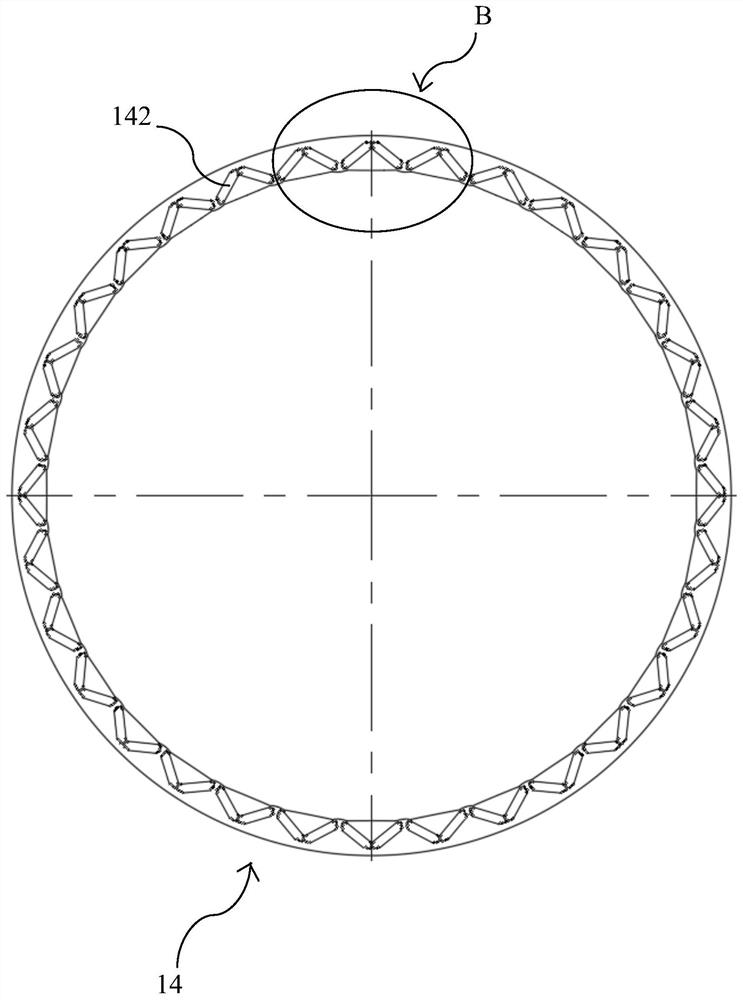

[0026] like Figure 1 to Figure 4 As shown, a 10-inch electric vehicle reluctance hub motor provided in this embodiment includes a rotor 1 and a stator 2. The rotor includes a rim 11, a housing 12, a rotor core 14 and a permanent magnet 15. The rim 11 is partially opened There is a valve core hole 13. In this embodiment, the rim 11 and the housing 12 are integrally formed by die-casting. The motor uses 36 slots to match 16 pairs of poles. The rotor core is provided with two magnetic steel slots 142 at a certain angle. A set of magnetic steel grooves 141, the magnetic steel grooves 142 on the rotor core 14 are evenly distributed on the circumference of a V-shaped distributed magnetic steel groove set 141, and the outer diameter of the rotor 1 in this embodiment is 220~230mm , Preferably, the outer diameter of the rotor 1 is 223~224mm.

[0027] In particular, the rotor core 14 in this embodiment is composed of 8 rotor core splits 143 connected end to end, all the rotor core spl...

Embodiment 2

[0031] The technical solutions in this embodiment are mostly the same as those in Embodiment 1. This embodiment only describes the different parts in detail, and the parts that are the same as those in Embodiment 1 will not be repeated here.

[0032] The outer diameter of the rotor 1 in this embodiment is 265~275mm, preferably, the outer diameter of the rotor 1 is 265~270mm; the outer diameter of the stator 2 is 190~245mm, more preferably, the outer diameter of the stator 2 is 225~230mm, this The outer diameter of the stator 2 of the embodiment is 227mm; the rib width of the stator 2 is 5.5-11mm, further preferably, the rib width of the stator 2 is 8.5-9.5mm, and the rib width of the stator 2 of this embodiment is 9.0-9.5mm The thickness of the yoke of the stator 2 is 3.5 ~ 8mm, further preferably, the thickness of the yoke of the stator 2 is 5.5 ~ 7mm, and the thickness of the yoke of the stator 2 of the present embodiment is 6.0 ~ 6.5mm; the internal diameter of the stator 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com