Rotor punching plate and permanent magnet motor

A technology of rotor punching and magnetic tiles, which is applied in the field of generators, can solve the problems of motor torque pulsation becoming larger and affecting motor noise, and achieve the effect of reducing torque pulsation and magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

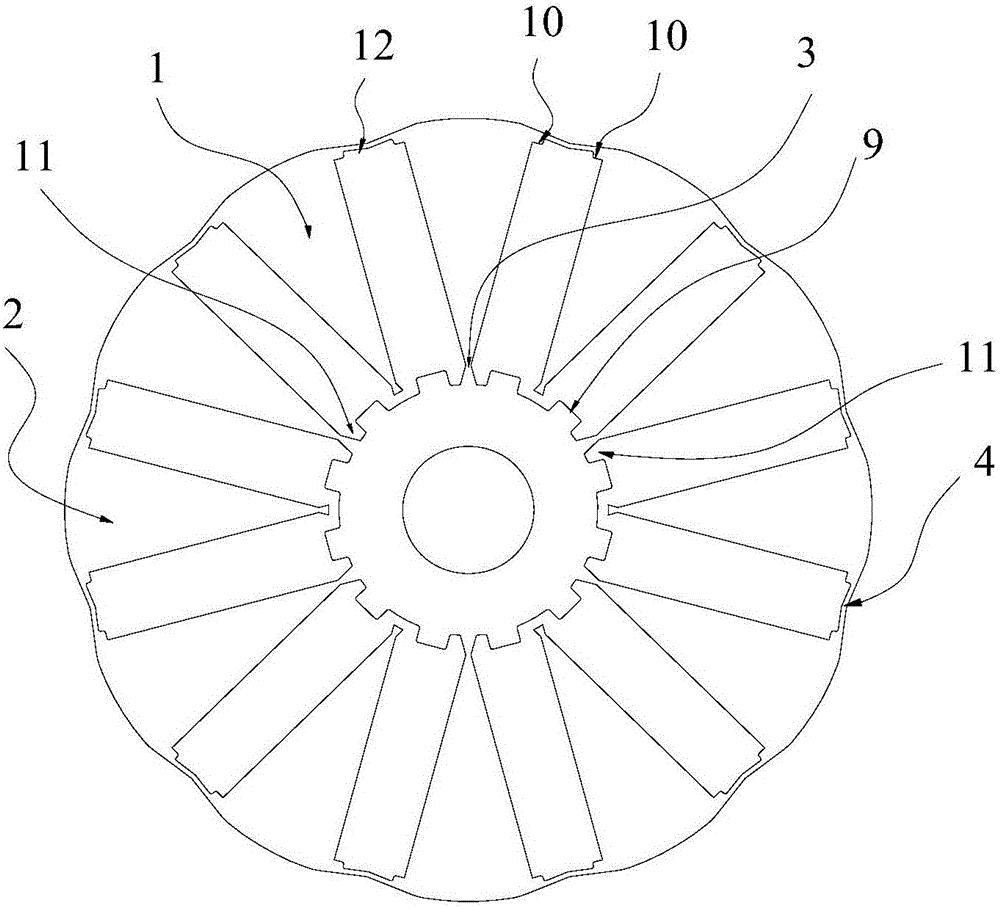

[0033] A rotor punch, such as Figure 2-3 As shown, it includes an iron core 1. A plurality of magnetic tile grooves 2 are evenly distributed along the circumference of the rotating shaft in the iron core 1. Each of the magnetic tile grooves 2 is arranged radially along the rotating shaft. Magnetic tiles are installed, and inner magnetic isolation bridges 3 are formed between adjacent magnetic tile grooves 2, and the inner magnetic isolation bridges 3 are disconnected from each other; a first positioning boss 9 is arranged on the inner side of the magnetic tile groove 2, Both sides of the first positioning boss 9 are respectively provided with inner air gaps 11; the outer side of the magnetic tile groove 2 is provided with two second positioning bosses 10, and the middle of the two second positioning bosses 10 An outer air gap 12 is provided. The optimal width of the magnetic tile groove 2 Among them, D is the minimum inner diameter of the inner side of the magnetic tile sl...

Embodiment 2

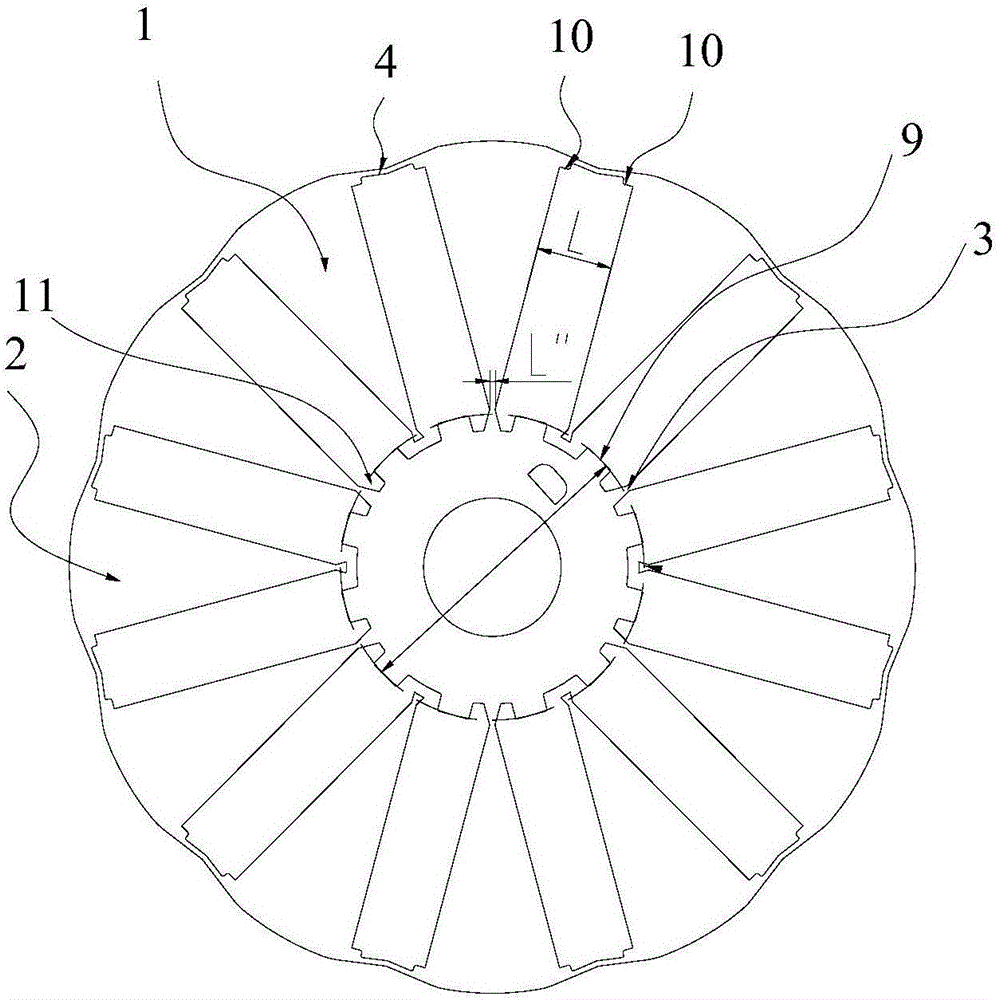

[0040] Different from Example 1, as Figure 4 As shown, a thin bridge 5 is provided in the middle of the phase-to-phase magnetic tile groove 2, and the magnetic tile groove 2 provided with the thin bridge 5 is divided into two small magnetic tile grooves 6 of equal size along the radial direction of the rotating shaft; that is, any adjacent One of the two magnetic tile grooves 2 is provided with a thin bridge 5, and the other is not provided with a thin bridge 5. The setting of the thin bridge 5 is mainly to strengthen the strength of the rotor punch structure and the magnetic field stability of the rotor punch during operation.

[0041] like Figure 5 As shown, the structure of the thin bridge 5 is linear, which is convenient for processing and installing magnetic tiles. A small magnetic tile is placed in the small magnetic tile groove 6, and the width of the small magnetic tile is the same as that of the magnetic tile.

[0042] like Image 6 As shown, the thin bridge 5 ca...

Embodiment 3

[0044] The difference from Embodiments 1 and 2 is that in order to unify the size of the magnetic tiles and obtain better strength of the rotor plate, as Figure 7As shown, the middle part of the magnetic tile groove 2 without thin bridge 5 is provided with a thin bridge 5 disconnected in the middle, and the magnetic tile groove 2 is divided into two small magnetic tile grooves 6 of equal size along the radial direction of the rotating shaft. That is, any two adjacent magnetic tile grooves 2 are provided with a thin bridge 5, but only one of the two thin bridges 5 is disconnected, and the magnetic tile groove 2 is divided into two small magnetic tiles of equal size along the radial direction of the rotating shaft. Slot 6. The disconnected thin bridge 5 blocks the magnetic flux leakage circuit between the poles, greatly reducing the magnetic flux leakage phenomenon here.

[0045] like Figure 5 As shown, the structure of the thin bridge 5 is linear, which is convenient for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com