Printed circuit board (PCB) wiring method and apparatus, and printed circuit board

A technology of printed circuit boards and wiring methods, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of discontinuous impedance and signal integrity of single-ended signal lines and differential signal lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

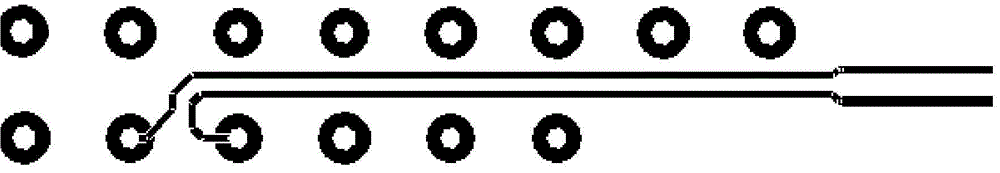

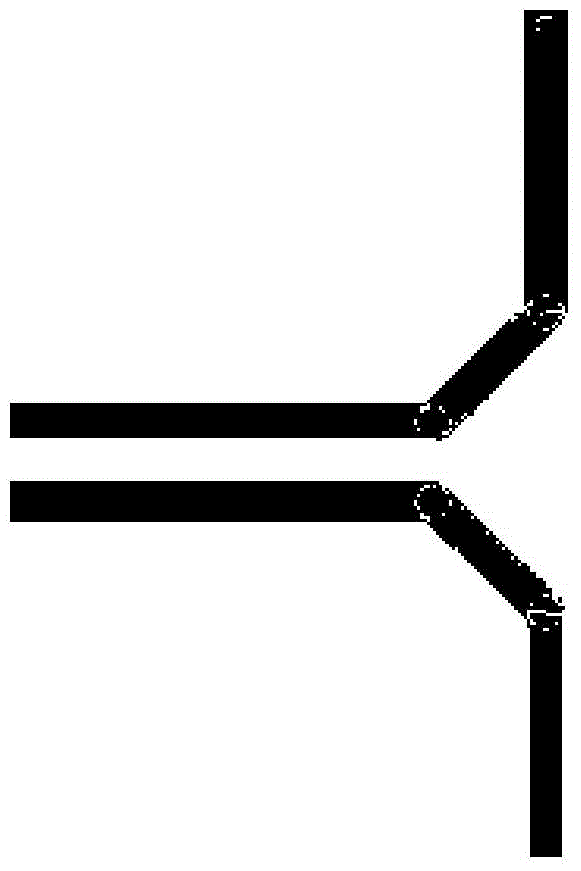

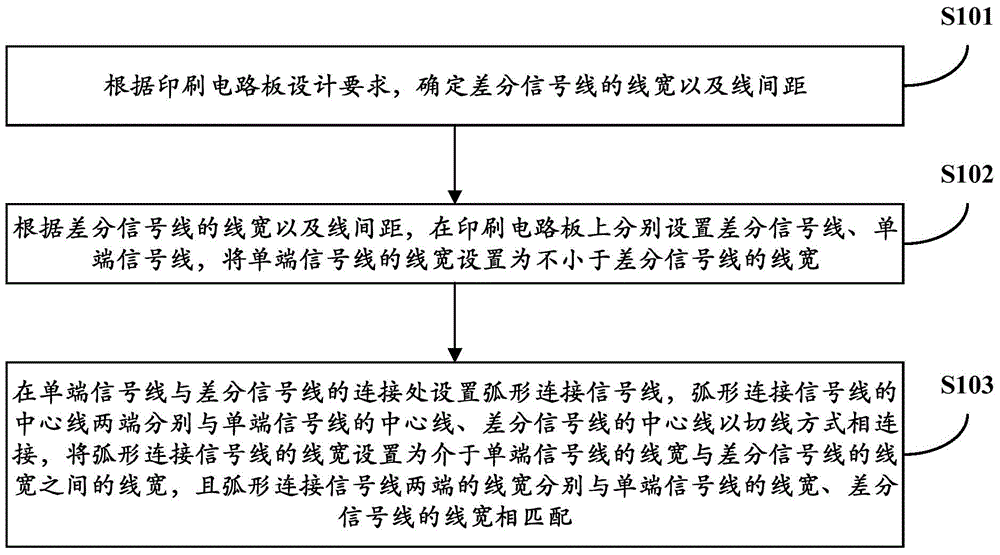

[0072] Figure 4 , 5 The structural diagrams of the single-ended signal line, the differential signal line wiring mode, and the arc-shaped connection signal line wiring mode in the SMA head area provided by Embodiment 2 of the present invention, as shown in Figure 4 , 5 As shown, this embodiment takes the wiring method of the SMA head as an example for illustration. Due to the physical size and twisting restrictions of the SMA head, the outgoing part of the SMA head must use a single-ended signal line to go out, and then the single-ended signal line is converted to a single-ended signal line. Differential signal lines, the wiring method is:

[0073]Make the single-ended impedance of the outgoing single-ended signal line 1 / 2 of the differential impedance of the differential signal line, use software to calculate the line width of the single-ended signal line, the line width and line spacing of the differential signal line, and place the single-ended wiring on the PCB Corres...

Embodiment 3

[0076] Figure 7 The structural schematic diagram of the wiring mode in the BGA area provided by Embodiment 3 of the present invention, as shown in Figure 7 As shown, this embodiment takes the wiring method of the BGA area as an example for illustration. Due to the limitation of the width of the routing channel, the existing method generally uses single-ended signal line routing in the part of the BGApin pin outlet, and in the BGA routing channel area Use smaller line width and line spacing, and use normal wiring outside the BGA area. However, this wiring method makes the line width of the differential signal line in the BGA area smaller, which will increase the loss. At the same time, the reduction of the line width will also increase the difference between the single-ended impedance and the differential impedance at the pin outlet, and Inside and outside the BGA area, the inflection points of different line widths and line spacing conversions will also produce impedance di...

Embodiment 4

[0079] Figure 8 A schematic structural diagram of a printed circuit board wiring device provided in Embodiment 4 of the present invention, as shown in Figure 8 As shown, the PCB wiring device includes:

[0080] Determination module 1, used to determine the line width and line spacing of the differential signal lines according to the design requirements of the printed circuit board;

[0081] The wiring module 2 is used to respectively arrange differential signal lines and single-ended signal lines on the printed circuit board according to the line width and line spacing of the differential signal lines determined by the determination module 1, and set the line width of the single-ended signal lines to not less than The line width of the differential signal line; it is also used to set an arc connection signal line at the connection between the single-ended signal line and the differential signal line, and the two ends of the center line of the arc connection signal line are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com