Control method and device for automatic pasta production equipment

A technology of production equipment and control methods, applied in the fields of dough forming and cutting equipment, dough processing, food science, etc., can solve the problems of high cost, residue pollution, insufficiency, etc., to achieve consistent taste, safe and healthy production process, and size consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

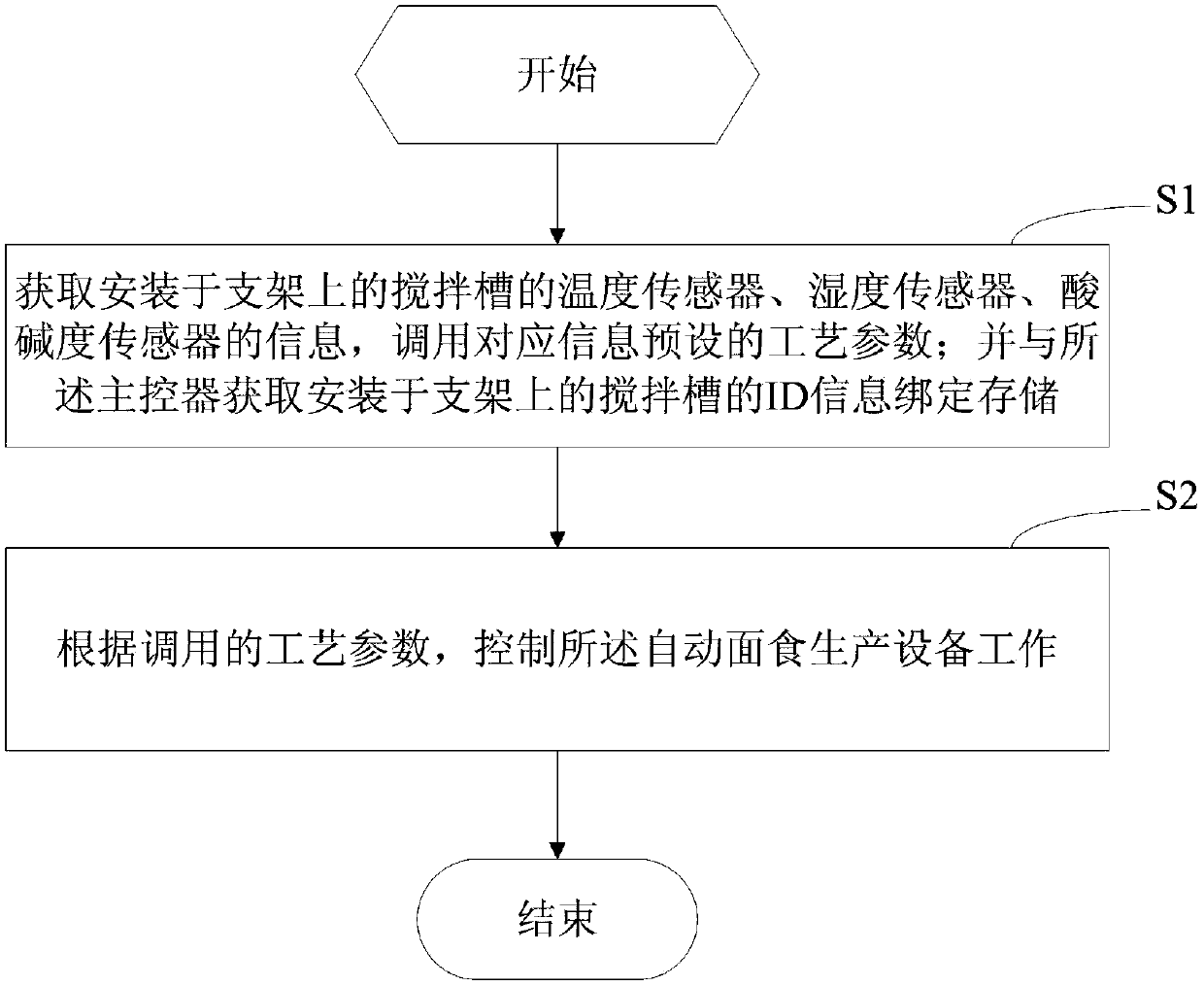

[0047] refer to figure 1 , is a schematic diagram of the control method of the automatic pasta production equipment in an embodiment of the present invention.

[0048] In one embodiment of the present invention, a control method for automatic pasta production equipment is proposed. The automatic pasta production equipment includes a support and a stirring tank detachably mounted on the support. The stirring tank is provided with unique ID information, a temperature sensor, a humidity sensor and a pH value. sensor, the control method includes:

[0049] Step S1, the main controller obtains the information of the temperature sensor, humidity sensor, and pH sensor of the stirring tank installed on the support, calls the process parameters preset by the corresponding information; and obtains the mixing tank installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com