Manufacturing method of infusion indwelling part connector for reducing hospital infection

A manufacturing method and a technology for nosocomial infection, applied in the field of medical devices, can solve problems such as troublesome operation, inability to puncture, pollution, etc., and achieve the effects of reducing the use of tape, facilitating operation, and reducing allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

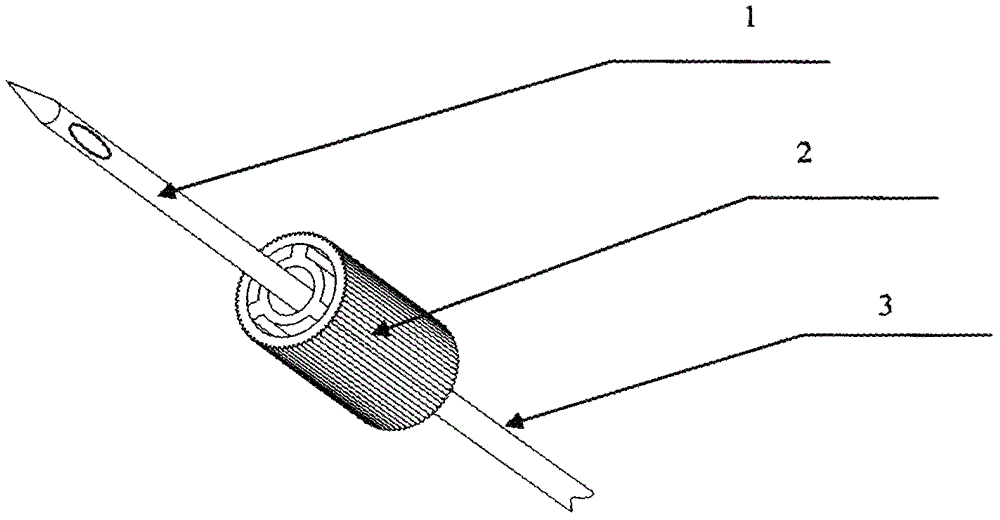

[0042] Embodiment one: see attached figure 1 Shown:

[0043] A method for manufacturing an infusion indwelling device connector that reduces nosocomial infections, comprising the following steps:

[0044] Step 1: Preparation of the steel needle 1: produce a steel needle 1 with a conical needle tip, the opening of which is located on the side wall of the needle tube behind the rear edge of the conical needle tip; the diameter of the steel needle 1 is 0.7 mm.

[0045] The second step: bonding the steel needle 1 and the needle holder 2 .

[0046] Step 3: or further bond or heat seal or weld or assemble with other components, pack, sterilize, and pass the inspection to obtain the indwelling infusion connector.

[0047] During use, the steel needle 1 is inserted towards the end face of the puncture-type connecting piece and inserted to the bottom. Since the steel needle 1 with a conical needle point is used, the probability of nosocomial infection is greatly reduced. The inject...

Embodiment 2

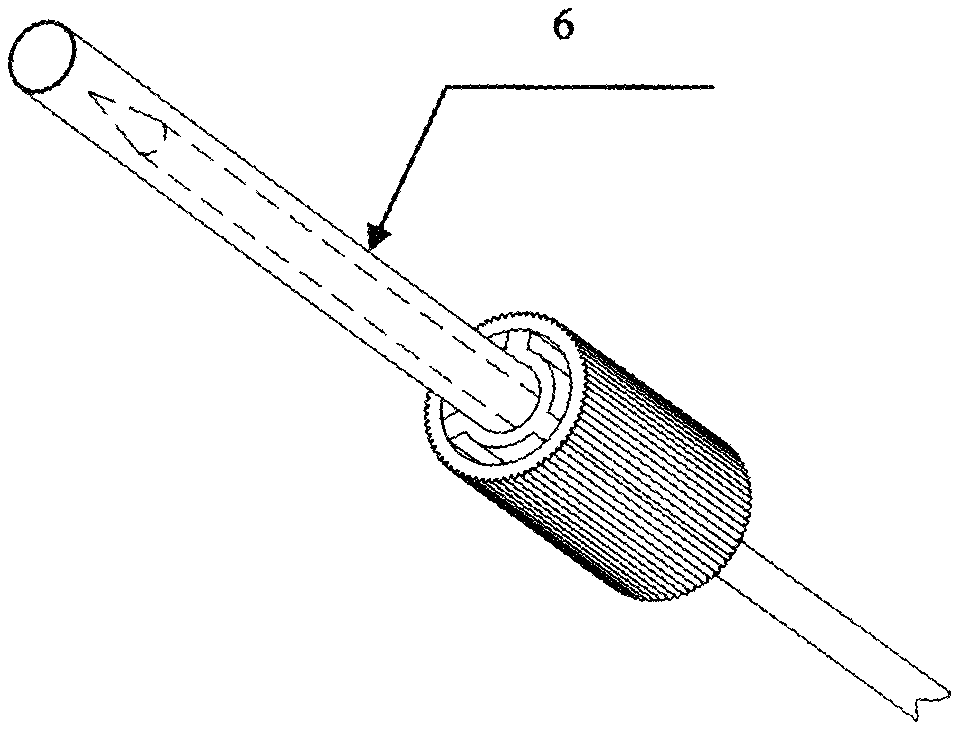

[0048] Embodiment two: see attached figure 1 , 2 , as shown in 4:

[0049] A method for manufacturing an infusion indwelling device connector that reduces nosocomial infection, the manufacturing method includes the following steps:

[0050]Step 1: Preparation of the steel needle 1: produce the steel needle 1 with a conical needle tip, the opening of which is located on the side wall of the needle tube behind the rear edge of the conical needle tip; the diameter of the steel needle 1 is 0.4mm or 0.6mm.

[0051] The second step: the 0.4mm steel needle 1 is bonded to the injection needle seat or the 0.6mm steel needle 1 is bonded to the infusion needle seat.

[0052] Step 3: Assembling with the injection barrel or bonding the infusion catheter 3 and bonding or assembling the conventional protective cap 6 and other accessories, packaging, sterilizing, and passing the inspection to obtain the infusion indwelling part infusion needle / device or syringe.

[0053] During use, the co...

Embodiment 3

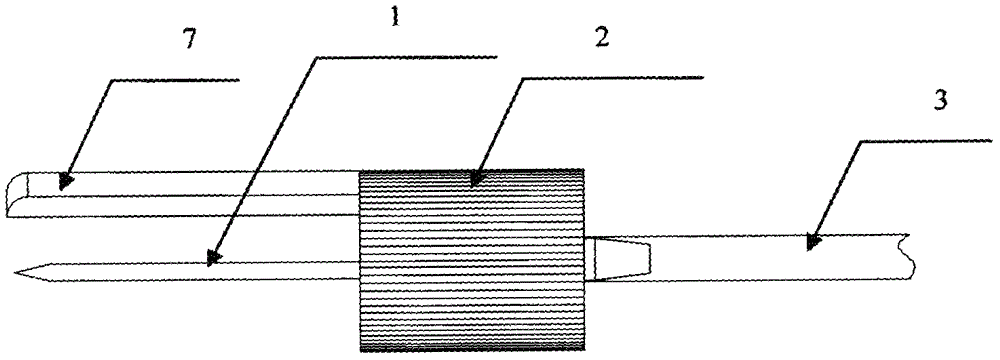

[0054] Embodiment three: see attached figure 1 , 3 Shown:

[0055] A method for manufacturing an infusion indwelling device connector that reduces nosocomial infection, the manufacturing method includes the following steps:

[0056] Step 1: Preparation of the steel needle 1: produce the steel needle 1 with a conical needle tip, the opening of which is located on the side wall of the needle tube behind the rear edge of the conical needle tip; the diameter of the steel needle 1 is 0.5mm or 0.8mm.

[0057] The second step: the 0.5mm steel needle 1 is bonded to the injection needle seat or the 0.8mm steel needle 1 is bonded to the infusion needle seat.

[0058] Step 3: After assembling with the injection device or bonding the infusion catheter 3 and other accessories, performing bonding or assembling, packaging, sterilizing, and passing the inspection, the infusion needle / device or syringe of the indwelling part for infusion is obtained.

[0059] In this example, the infusion n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com