An intelligent gluing end effector and its control method

An end-effector and gluing technology, which is applied to coatings, devices that apply liquid to surfaces, etc., can solve the problems of inaccurate gluing position, unguaranteed gluing quality, low gluing efficiency, etc. Partial repair work, uniform and continuous glue dispensing, and quick response to glue dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

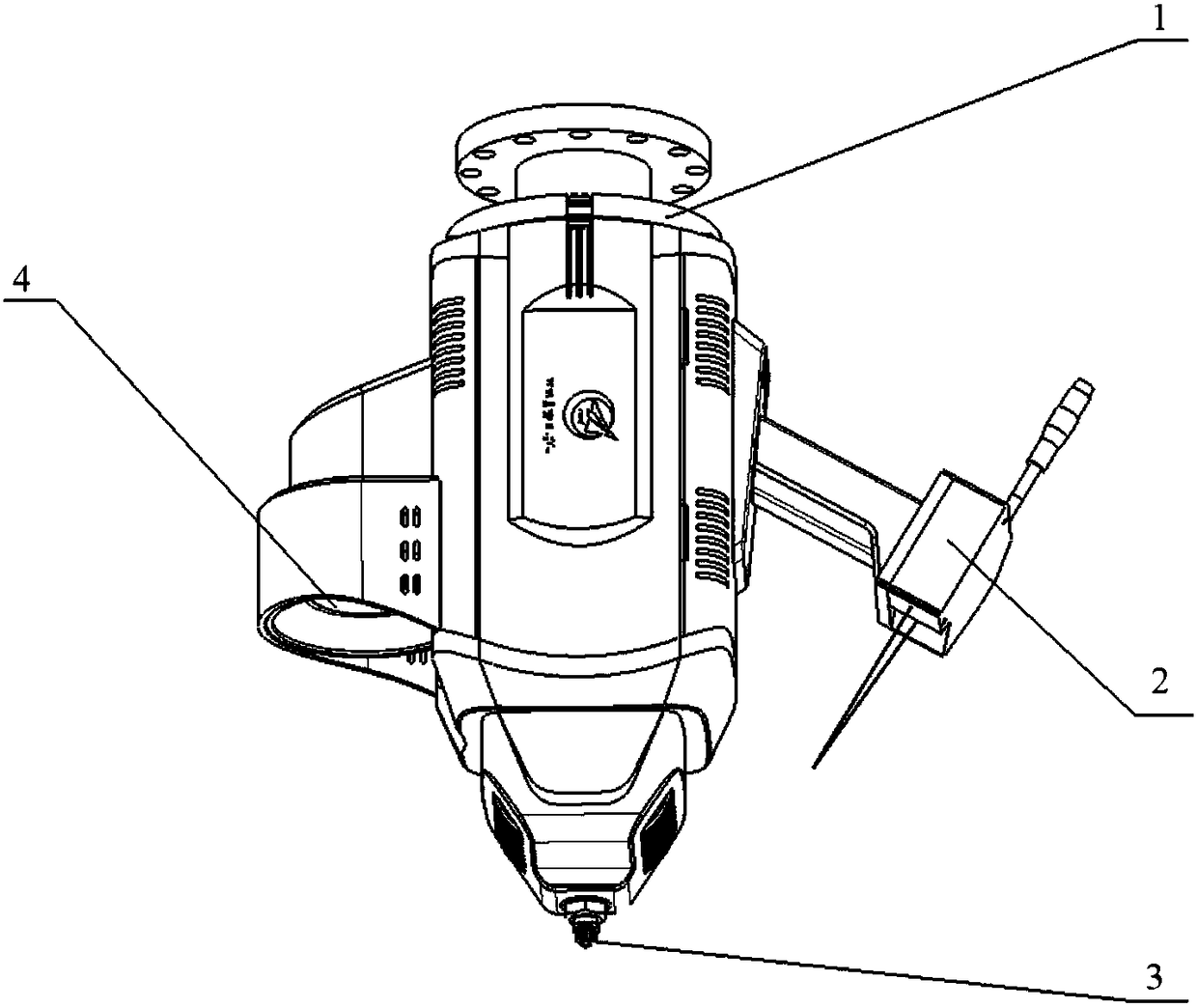

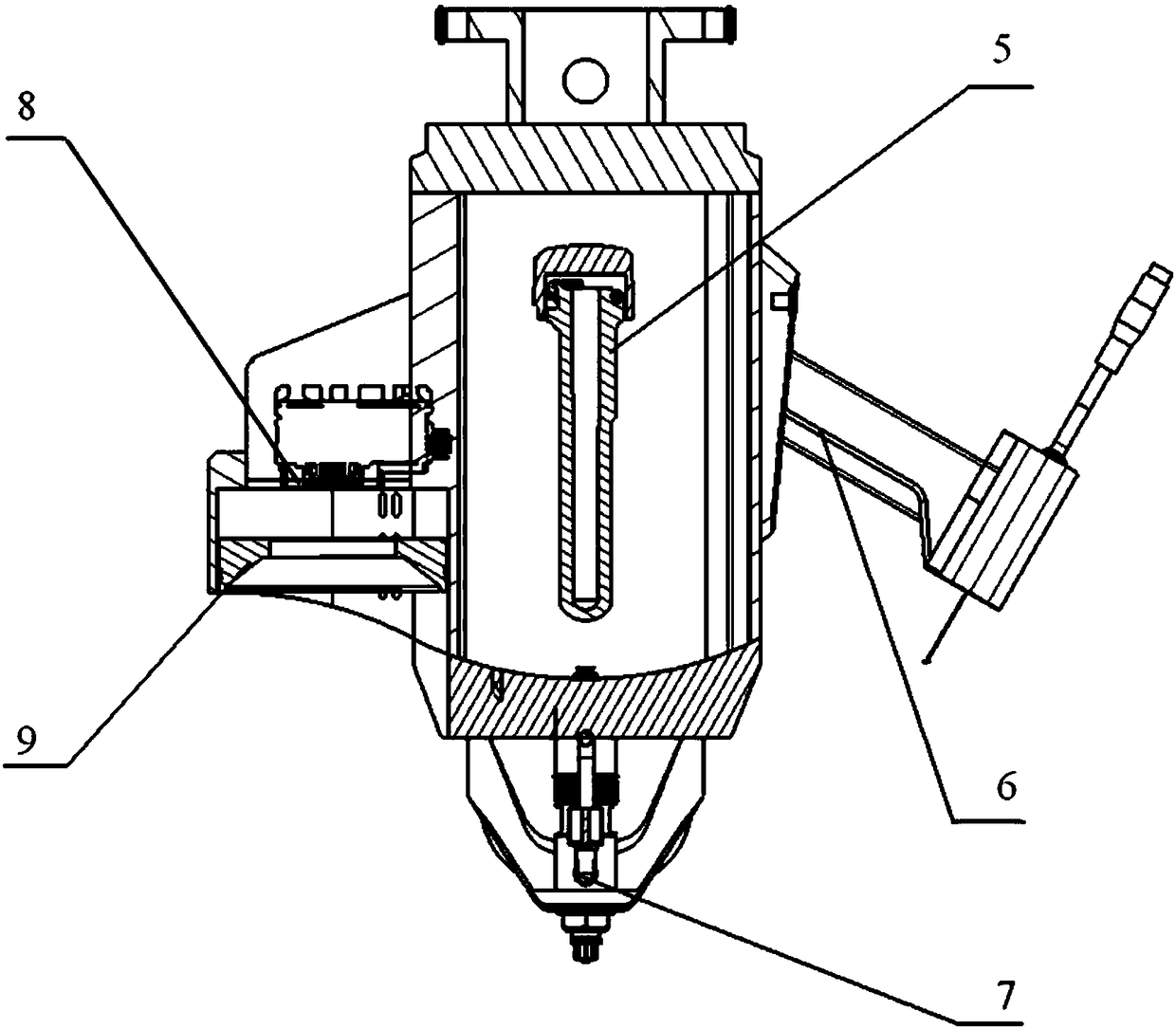

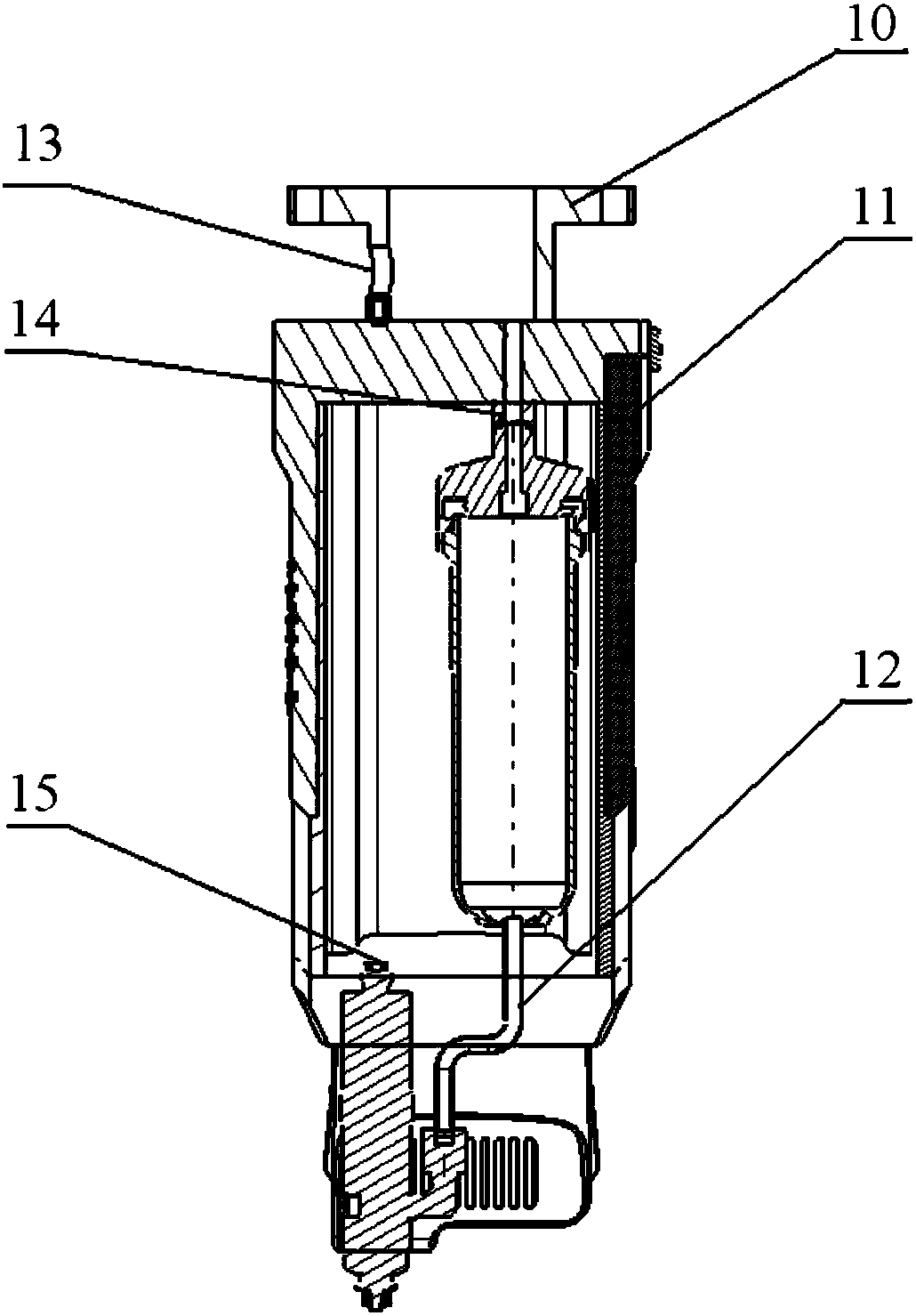

[0036] Such as Figure 1~3 As shown, the intelligent gluing end effector of the present invention includes a housing 1, a laser scanning sensor 2, a pressure glue barrel 5, a piston dispensing valve 7 and a visual camera 4, wherein the visual camera 4 is installed on one side of the housing 1 , the laser scanning sensor 2 is installed on the other side of the housing 1; the pressure rubber barrel 5 is built in the housing 1, and the upper end is connected to the external compressed air pipe; the piston type dispensing valve 7 is installed inside the housing 1, and the entire actuator The front end is connected with the pressure rubber barrel 5 through a hose.

[0037] In this embodiment, the housing 1 is a hollow square column structure, a connecting flange 10 is installed at the rear end of the housing 1 , and a movable side door 11 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com