Fully automatic dispensing device and dispensing method

A dispensing device, fully automatic technology, applied to the device for coating liquid on the surface, coating, etc., can solve the problems of poor flexibility and adjustability of the device, low positioning accuracy, and low quality of optical device dispensing. The effect of less glue dispensing at time points, improved applicability, and improved dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiment of automatic dispensing device

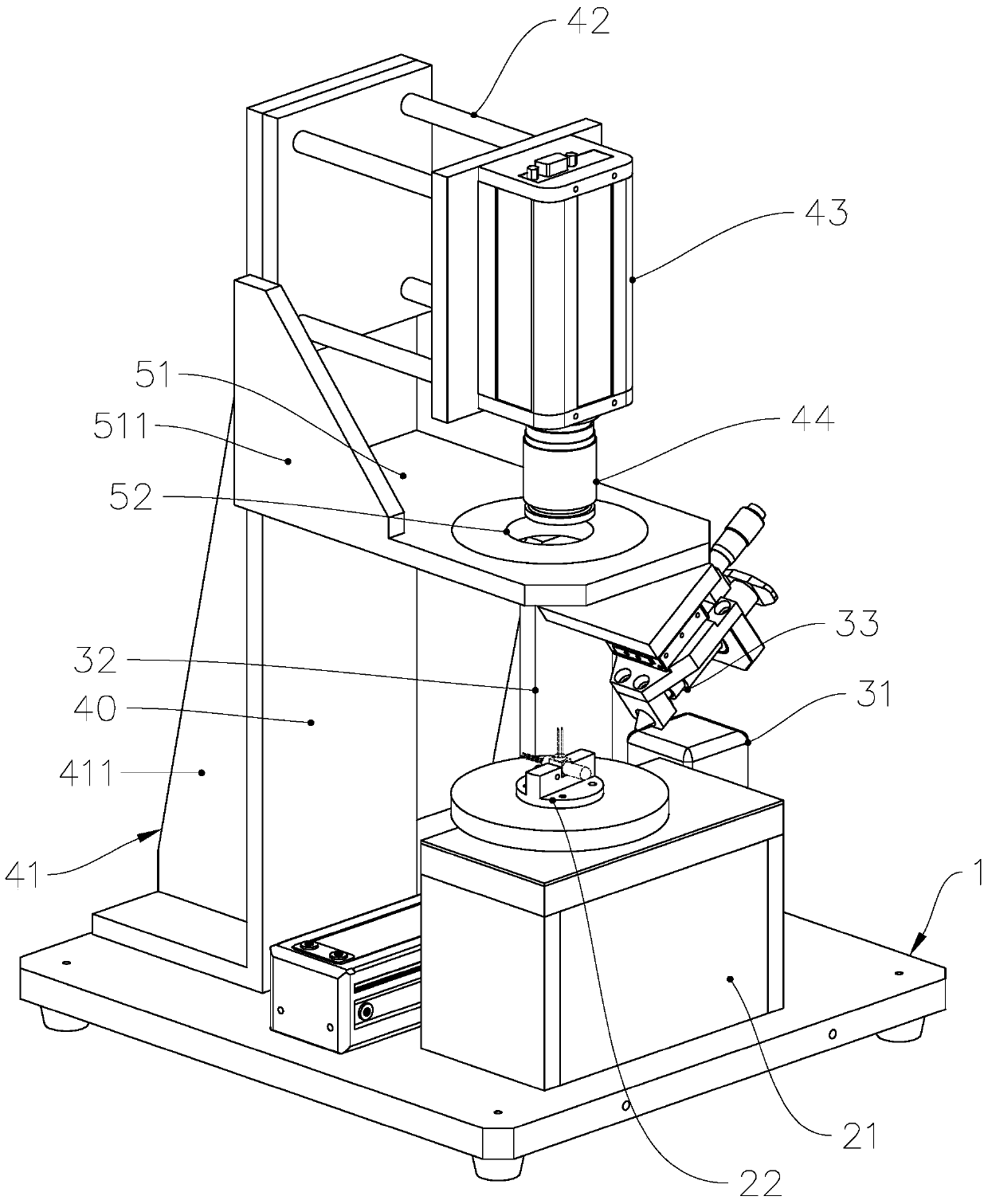

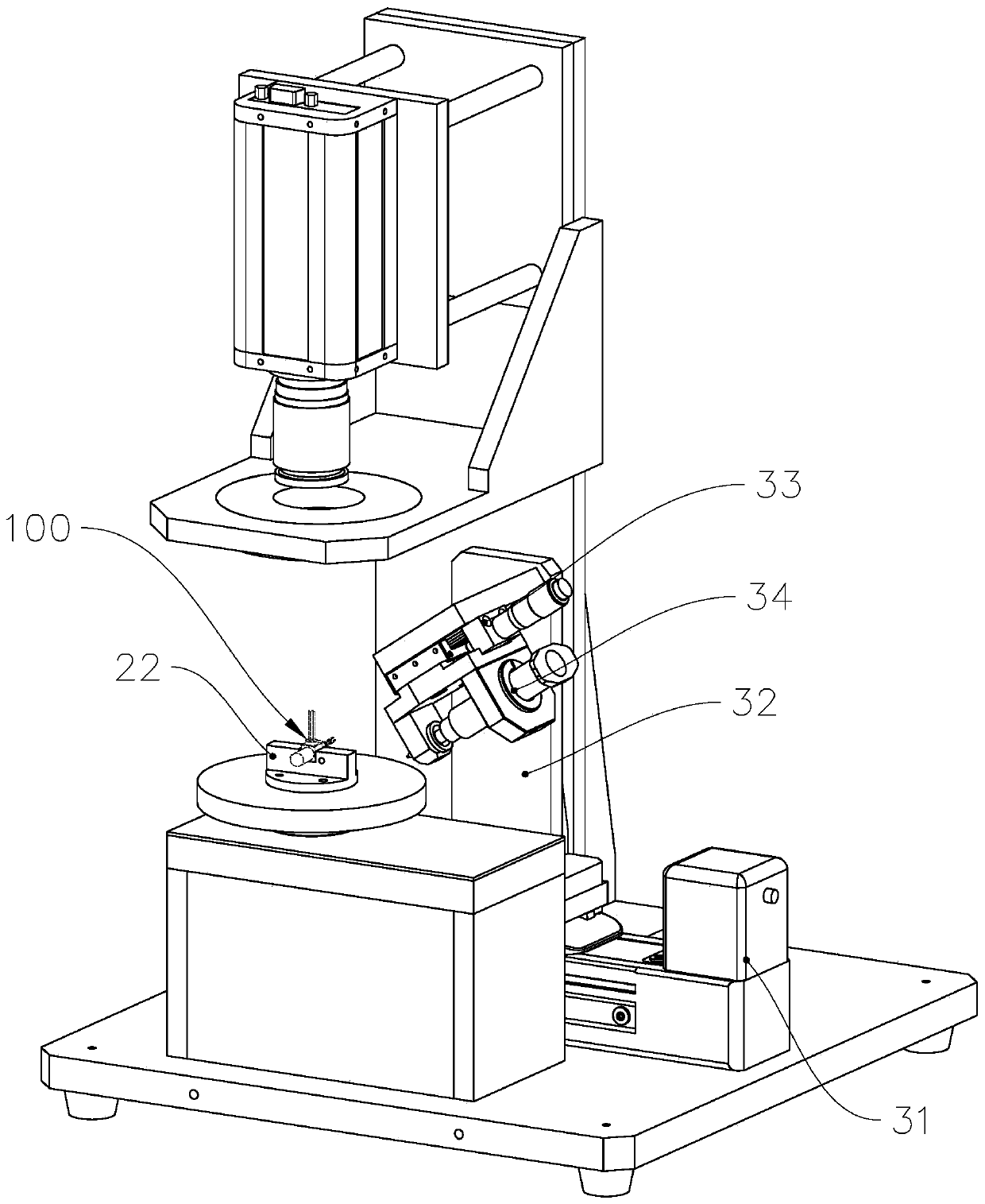

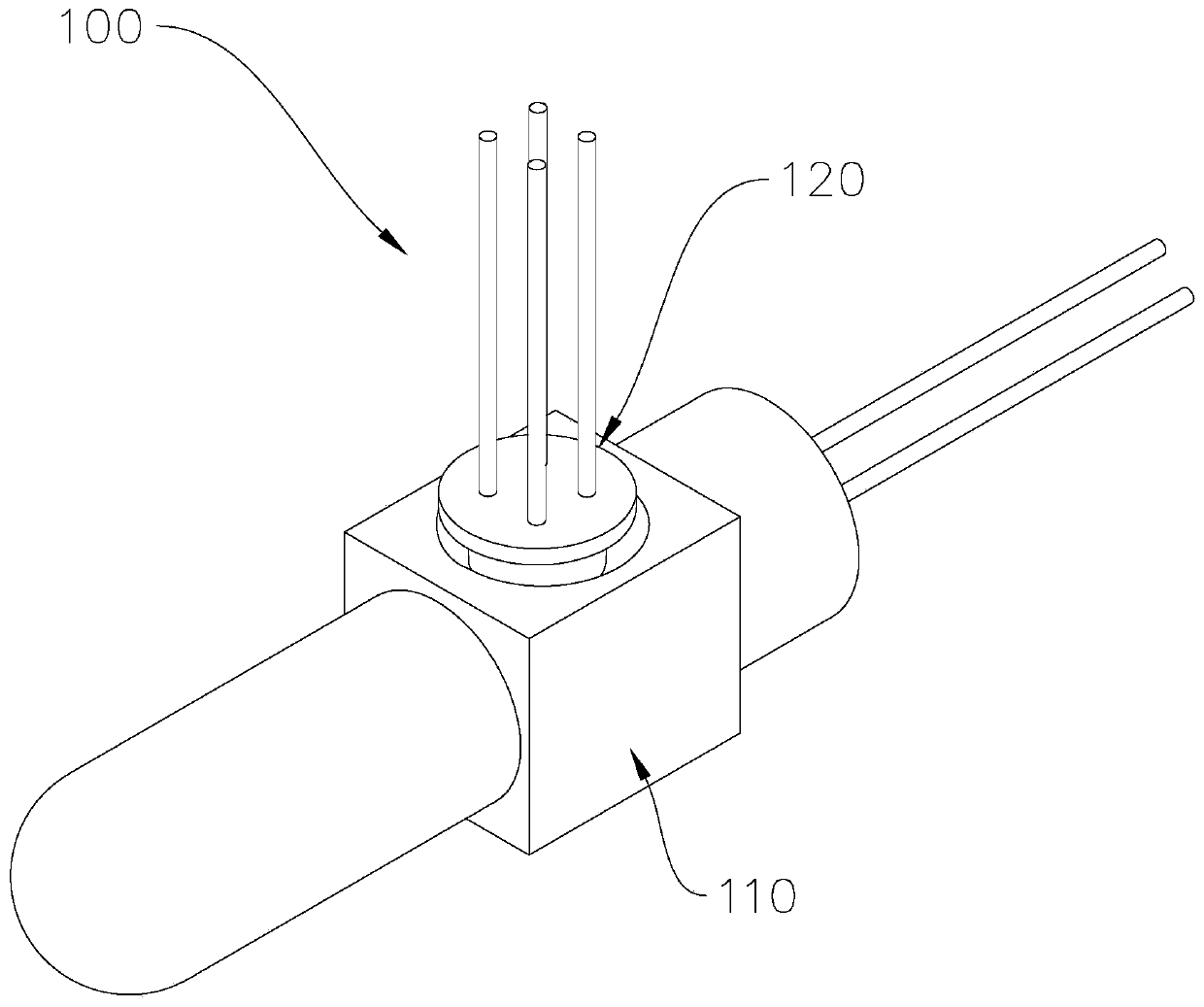

[0037] see figure 1 and figure 2 , figure 1 and figure 2 It is the structural diagram of different viewing angles of the automatic dispensing device. The automatic dispensing device is used for the packaging process of the base and PD in the BOSA device 100. The automatic dispensing device includes a base plate 1, and the rotation drive part 21, the translation drive part 31 and the stand 41 are all fixedly installed on the base plate 1.

[0038] The rotation driving part 21 includes a rotation power source such as a servo motor to provide torque output, and the rotation power source is connected to a controller, and the controller can send a control signal to the rotation power source. The output shaft of the rotating drive part 21 is connected with a clamp 22, the clamp 22 is a circular turntable clamp, the center of the clamp 22 is provided with a clamping position, and a bolt locking device is arranged at the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com