Automatic food waste smashing and squeezing integrated equipment

A kind of food waste and automatic technology, applied in the direction of presses, solid waste removal, manufacturing tools, etc., can solve the problems of cumbersome operation process and a large number of equipment, and achieve the effect of good oil and water content, reduced water content, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

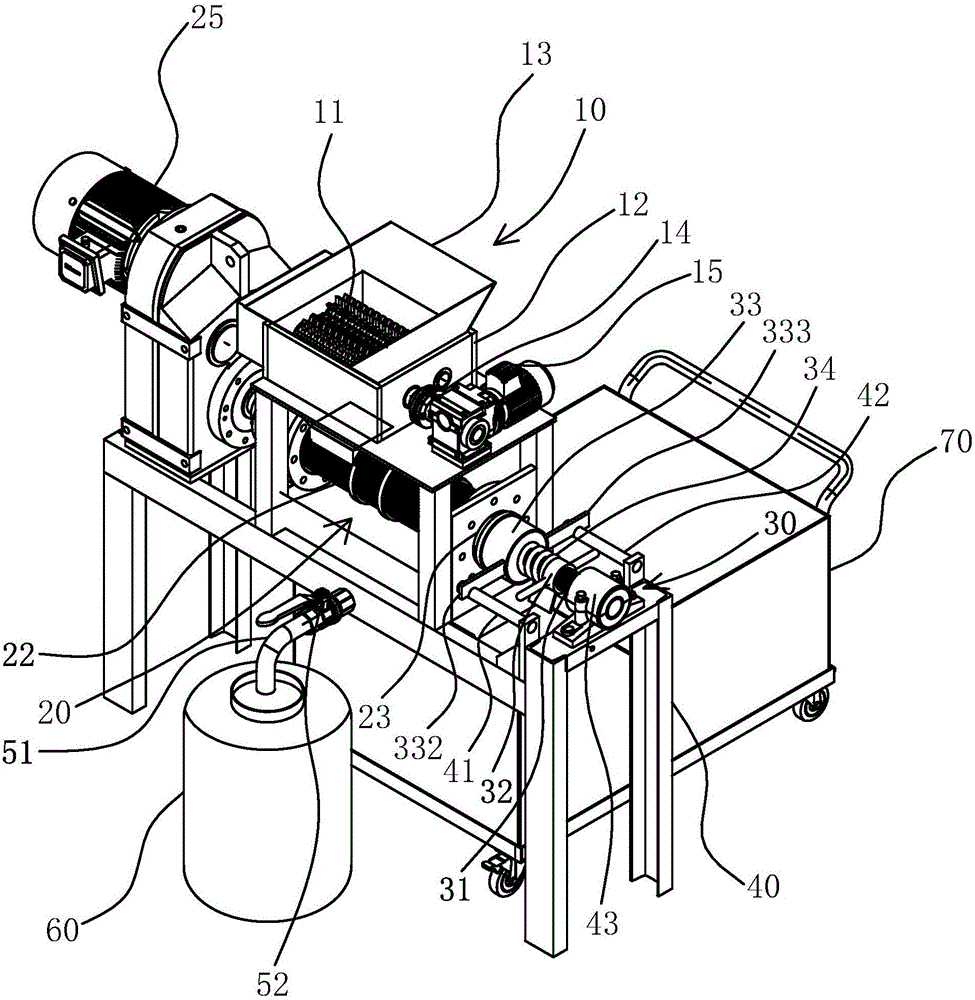

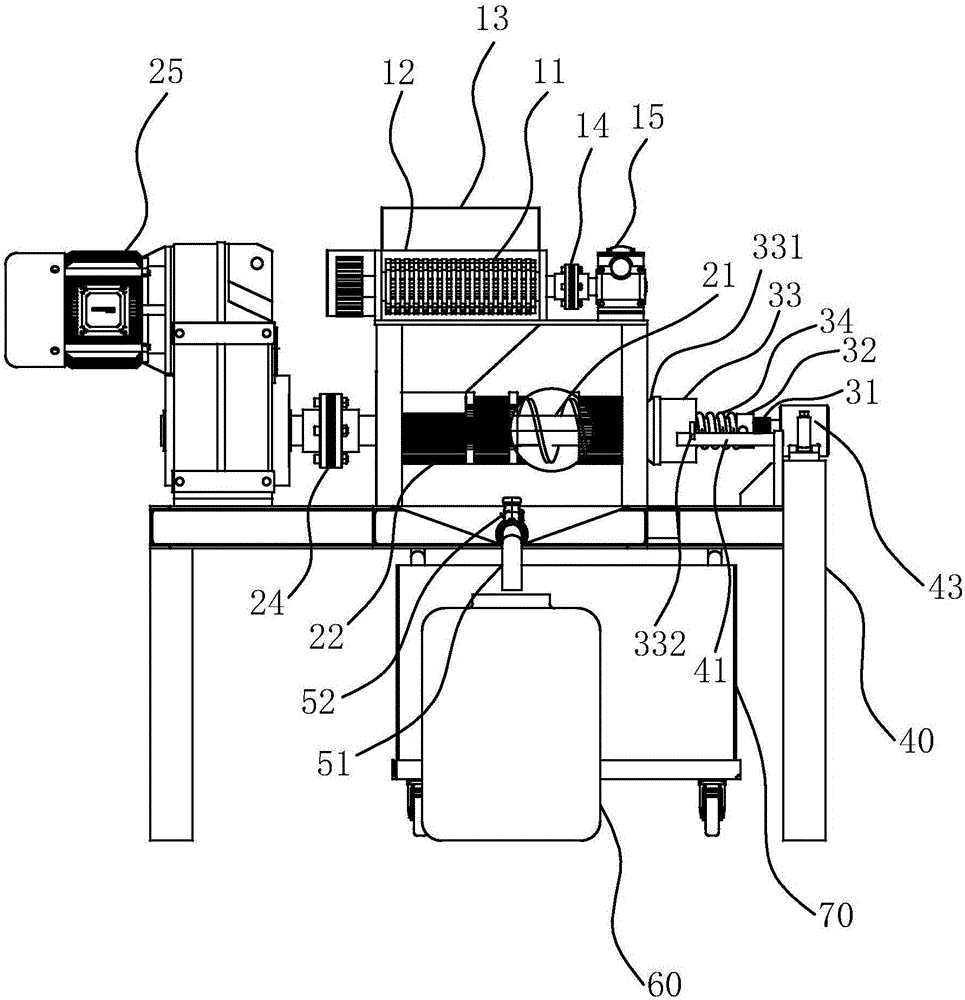

[0030] Below in conjunction with accompanying drawing, technical solution of the present invention is described:

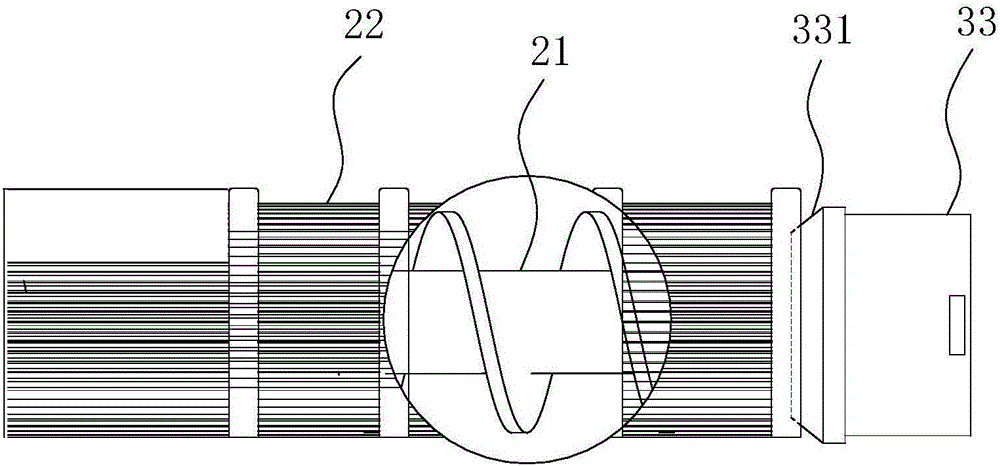

[0031] The automatic crushing and pressing integrated equipment for catering waste of the present invention includes a crushing mechanism 10, a screw conveying mechanism 20, and a compression plugging mechanism 30. The screw conveying mechanism 20 includes a spiral conveying roller 21, and the outer coaxial of the spiral conveying roller 21 is A filter cartridge 22 is sleeved for filtering oil and water in the pulverized food waste. One end of the filter cartridge 22 is provided with a feed port, and the other end forms a slag discharge port 23. The discharge port of the crushing mechanism 10 is connected to the feed port. connected to each other, the compression plug mechanism 30 includes an adjustment screw 31, a compression nut 32 sleeved on the adjustment screw 31, and a compression plug 33 located at the slag discharge port 23, the compression A compression s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com