Automatic discharging device

A technology of automatic cutting and feeding mechanism, applied in metal processing and other directions, can solve the problems of high investment cost, waste generation, waste of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

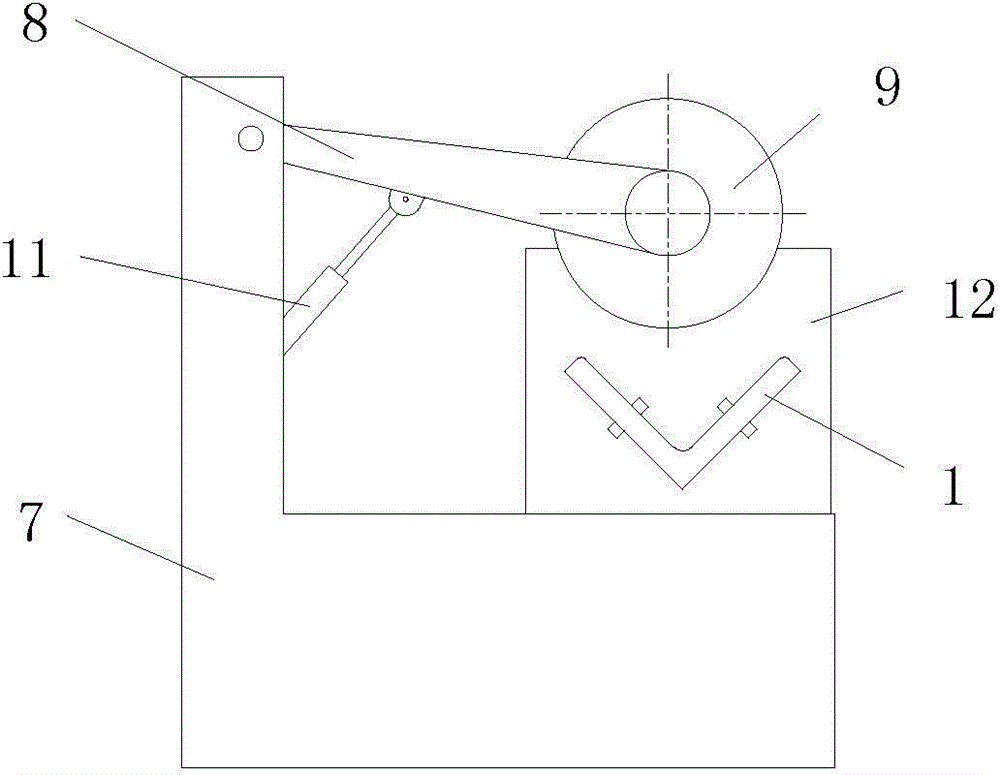

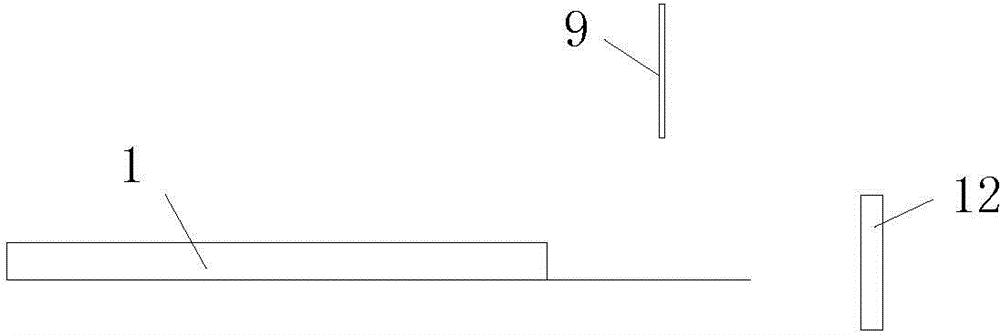

[0028] Such as figure 1 Shown is a schematic structural view of an embodiment of the automatic unloading device of the present invention. The automatic blanking device of this embodiment includes a blanking and cutting mechanism, a feeding mechanism cooperating with the blanking and cutting mechanism, and a blocking mechanism for positioning workpieces. Blanking cutting mechanism comprises frame 7, and the knife rest 8 that is installed on described frame 7 and the cutting tool 9 that is installed on described knife frame 8 are rotated, and frame 7 is provided with the motor that is used to drive cutting tool 9 rotations 10. An oil cylinder 11 for driving the tool post 8 to rotate is provided between the frame 7 and the tool post 8 .

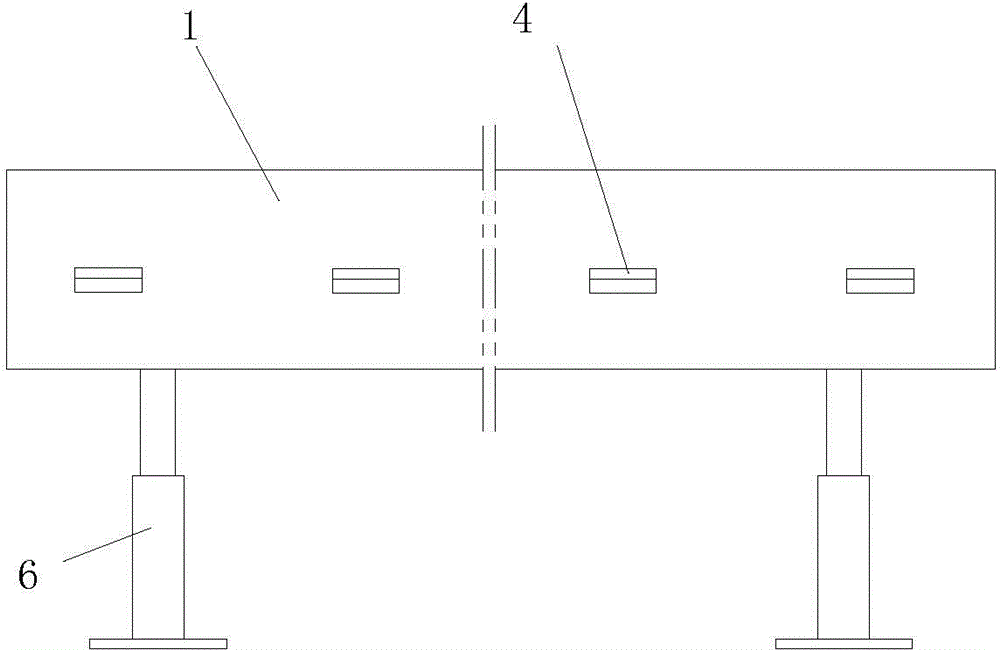

[0029] The feeding mechanism includes a V-shaped track body 1 arranged at the feeding end of the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com