A cutting machine with sliding curtain

A sliding curtain and cutting machine technology, which is applied in metal processing and other directions, can solve problems such as high noise, high energy consumption in production and operation, and expensive equipment, so as to reduce complexity and manufacturing costs, reduce use and maintenance costs, and reduce The effect of power and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

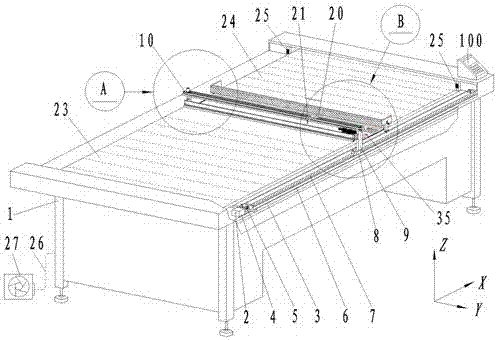

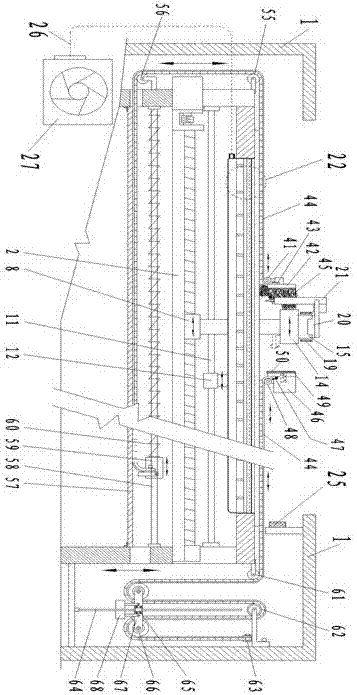

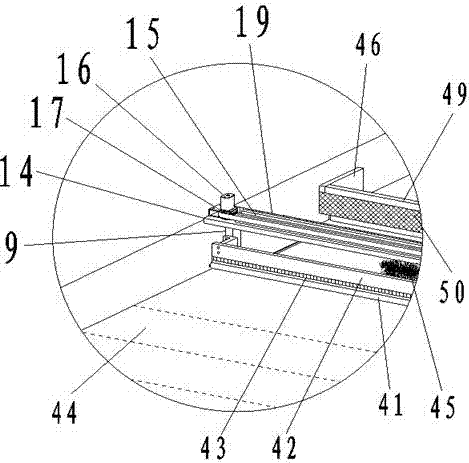

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] to combine Figure 1 to Figure 6 , the cutting machine of the present invention includes a frame 1, an X-axis driving module 2, a Y-axis driving module 10, an auxiliary X-axis guide rod 11, an auxiliary X-axis slider 12, an auxiliary X-axis lug plate 13, a cutting head 21, Bearing platform 22, left sliding row of curtains 23, right sliding row of curtains 24, curtain cover clutch 35, pressure-resistant bellows 26, suction fan 27 and microcomputer 100.

[0024] The platform 22 is located above the frame 1 and is made up of an airtight cabin 28, a grid layer 30, a coarse-mesh grate layer 31, a fine-mesh grate layer 32, a sponge pad 33 and a non-woven fabric layer 34. The airtight cabin 28 The top is open and is provided with a grid layer 30, and the top of the grid layer 30 is successively provided with a coarse-mesh grate layer 31, a fine-mesh grate layer 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com