A high-resistance water-based solar module edge-sealing tape

A solar module, water-based technology, applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc. problem, to achieve the effect of reduced thickness, good aging resistance, softness and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

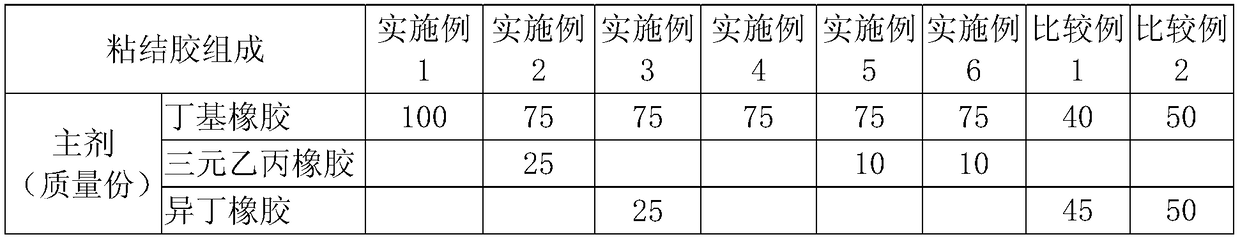

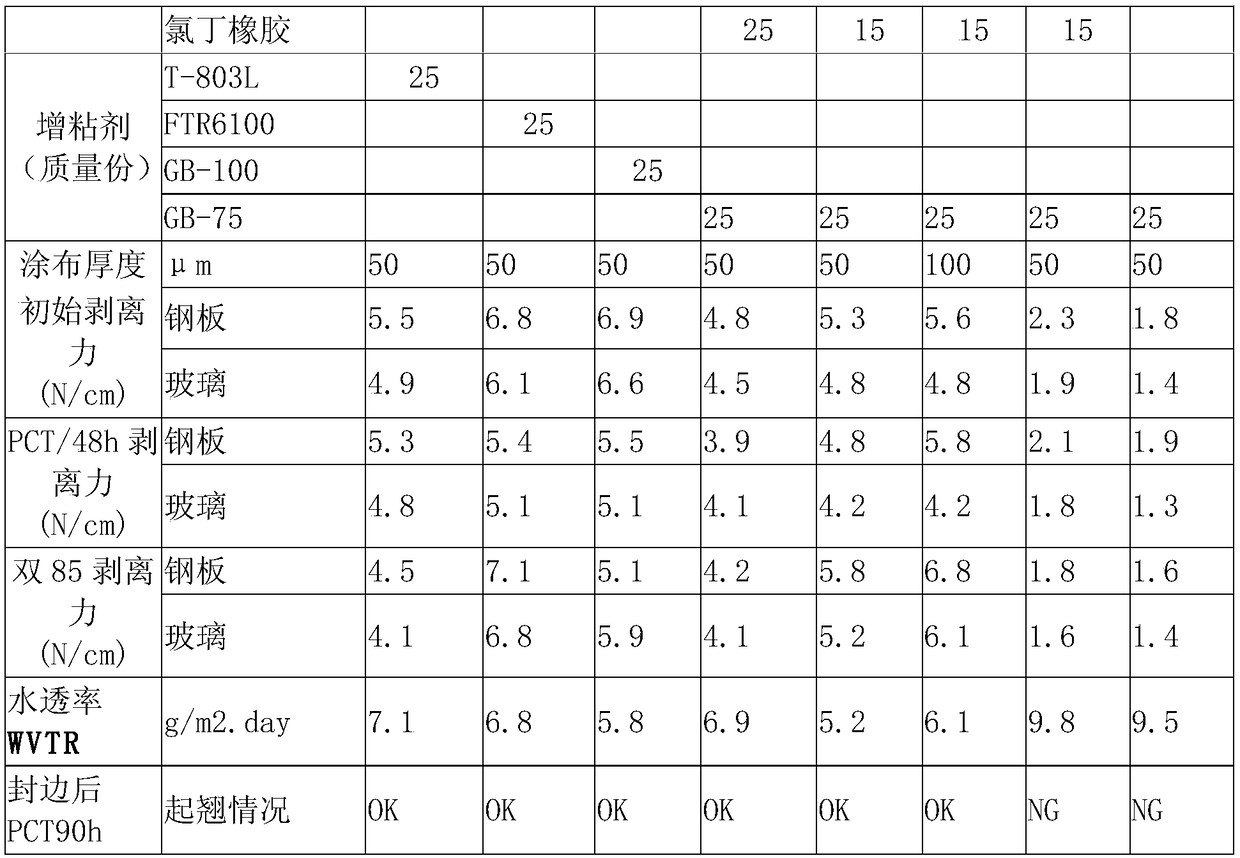

[0019] Example 1. 100 parts of butyl rubber, 25 parts of tackifying resin T-803L, added toluene to dissolve into a solution, coated on the release film, the thickness of the dry glue is 50 μm, and transferred to a PVC substrate with a thickness of 100 μm after drying (Insulation buffer PVC film) to make tape products.

Embodiment 2

[0020] Embodiment 2. 75 parts of butyl rubber, 25 parts of EPDM, 25 parts of tackifying resin FTR6100, add toluene and dissolve into a solution, coat the release film, the dry glue thickness is 50 μm, transfer to On a PVC base material (insulating buffer PVC film) with a thickness of 100 μm, an adhesive tape product was prepared.

Embodiment 3

[0021] Example 3. 75 parts of butyl rubber, 25 parts of isobutyl rubber, 25 parts of tackifying resin GB-100, add toluene to dissolve into a solution, coat the release film, the thickness of the dry glue is 50 μm, and transfer to the thickness after drying Tape products were prepared on a 200 μm PVC substrate (insulating buffer PVC film).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com