A renovating dry cleaning agent for suede leather products and a preparing method thereof

A technology for leather products and dry cleaning agents, applied in the direction of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of not having cleaning function, increasing time cost, affecting the next use, etc., to achieve cleaning and Renovation is simple and fast, and the effect of reducing energy usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

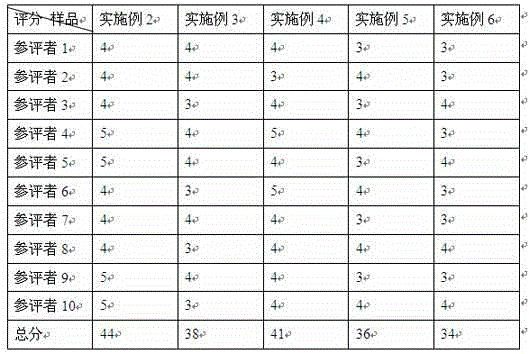

Examples

Embodiment 1

[0061] A dry cleaning agent for suede leather products containing a refurbishment agent, the raw materials of the dry cleaning machine include anionic surfactant, fatty alcohol polyoxyethylene ether-9, alkyl glucoside, isomerized fatty alcohol polyoxyethylene ether, water-soluble silicone oil , amino silicone oil, oxidized lauryl amidopropyl dimethyl betaine, ethylene glycol, odorless ethanol, citric acid, sodium N-methylolglycinate, essence and deionized water, the weight and number ratio of each raw material is:

[0062] Anionic surfactant 0.5~2

[0063] Fatty alcohol polyoxyethylene ether-90.1~1

[0064] Alkyl glycoside 0.3~0.5

[0065] Isomerized fatty alcohol polyoxyethylene ether 0.5~2.5

[0066] Water-soluble silicone oil 0.1~0.3

[0067] Amino silicone oil 0.01~4

[0068] Oxidized lauryl amidopropyl dimethyl betaine 0.02~0.1

[0069] Ethylene glycol 3~5

[0070] Odorless ethanol 0~50

[0071] Citric acid 0.1~0.3

[0072] Sodium N-hydroxymethylglycinate 0.1~0.3 ...

Embodiment 2

[0086] This embodiment is a preferred scheme based on embodiment 1, the quality of the raw materials used is the same as that of embodiment 1, and the weight and number ratio of each raw material is:

[0087] AES-22.0

[0088] AEO-90.25

[0090] Isomerized fatty alcohol polyoxyethylene ether 1.2

[0091] Water-soluble silicone oil 0.3

[0092] Amino silicone oil 0.05

[0093] Oxidized lauryl amidopropyl dimethyl betaine 0.02

[0094] Ethylene glycol 3

[0095] Odorless Ethanol 20

[0096] Citric acid 0.2

[0097] Sodium N-hydroxymethylglycinate 0.2

[0098] Flavor 0.3

[0099] deionized water to 100.

Embodiment 3

[0101] This embodiment is a preferred scheme based on embodiment 1, the quality of the raw materials used is the same as that of embodiment 1, and the weight and number ratio of each raw material is:

[0102] AES-30.5

[0103] AEO-90.5

[0104] Alkyl glycoside 0.4

[0105] Isomerized fatty alcohol polyoxyethylene ether 2.0

[0106] Water-soluble silicone oil 0.15

[0107] Amino silicone oil 1.0

[0108] Oxidized lauryl amidopropyl dimethyl betaine 0.05

[0109] Ethylene glycol 3.0

[0110] Odorless Ethanol 20

[0111] Citric acid 0.2

[0112] Sodium N-Hydroxymethylglycinate 0.15

[0113] Flavor 0.3

[0114] deionized water to 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com