Yarn lifting clamp

A technology of yarn clamp and yarn bobbin, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of affecting the spinning quality, messy bobbin yarn, polluting bobbin yarn, etc., and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

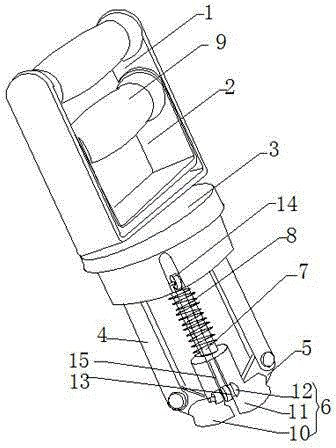

[0014] Such as figure 1 The yarn holding clamp shown includes an outer frame 1 and an inner frame 2; a support 3 is installed at the bottom of the outer frame 1; a through hole is respectively opened at the center of the support 3 and the outer frame 1; A straight groove 4 is hinged on both sides of the seat 3; a connecting strip 5 is hinged on the front side of the straight groove 4; a yarn tube fitting device 6 is installed between the connecting strips 5; the inner frame 2 is connected by a straight rod 7 To the yarn tube fitting device 6; the straight rod 7 penetrates the through hole; the inner side of the straight rod 7 between the support 3 and the yarn tube fitting device 6 is installed with a spring tube 8; the outer frame 1 and A handshake 9 is installed between the inner frames 2 respectively.

[0015] The yarn tube attaching device 6 is composed of a left half 10 and a right half 11 fixed by a nut 12.

[0016] A lower guide wheel 13 is installed on the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com