Belt-type vacuum dehydration device

A technology of vacuum dehydration and vacuum water absorption, which is used in textiles, liquid/gas/vapor removal by suction, fabrics, etc., can solve the problems of small adaptability, high energy consumption, and high overage rate, and achieves continuous, applicable Wide range, friction-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

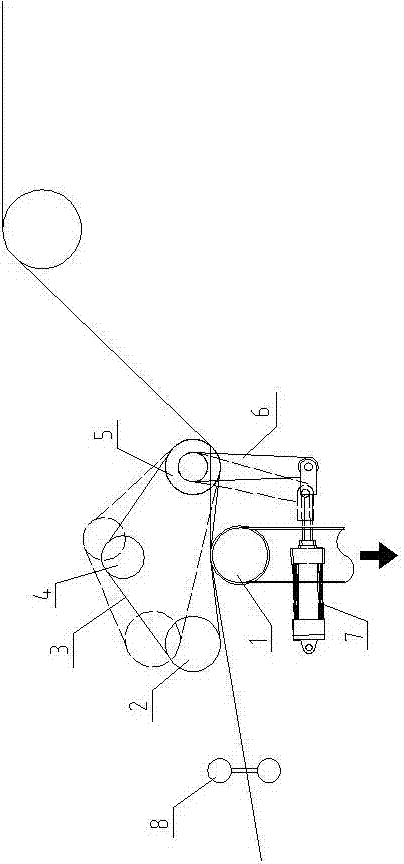

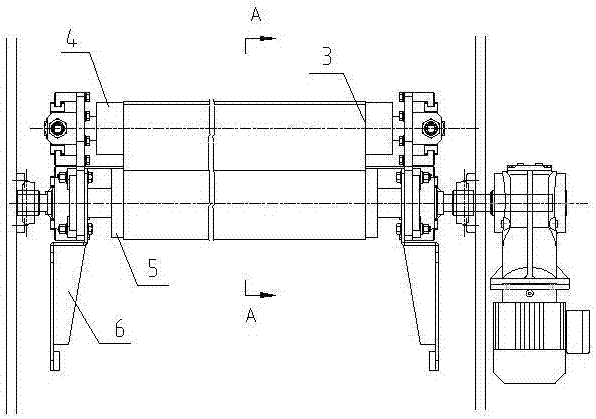

[0021] refer to Figure 1-5 , a belt-pressing vacuum dehydration device, comprising a vacuum suction device for sucking moisture in the fabric and a rotary belt press mechanism arranged above the vacuum suction device to adjust the water permeability of the fabric;

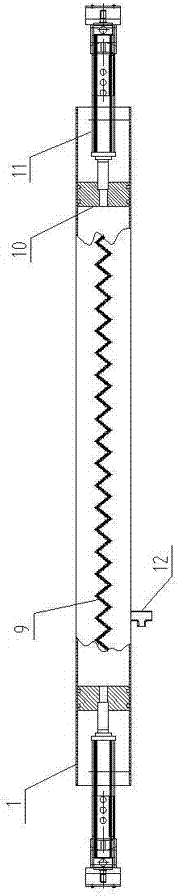

[0022] The vacuum water suction device is provided with a vacuum suction pipe 1, and a water suction port 9 is arranged axially on the pipe wall from one end of the vacuum suction pipe 1 to the other end, and the two ends of the vacuum suction pipe 1 are provided with corresponding to the width of the fabric to be adsorbed. The sealing piston 10 of the vacuum suction pipe 1 is provided with a servo drive mechanism 11 for driving the sealing piston 10, and the cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com