Cleaning assembly for bridge

A technology for cleaning components and bridges, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of loss of dust collection function, damage to bridge surface cleaning devices, and easy to be filled with various debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Combine below Figure 1-4 Embodiments of the present invention will be described.

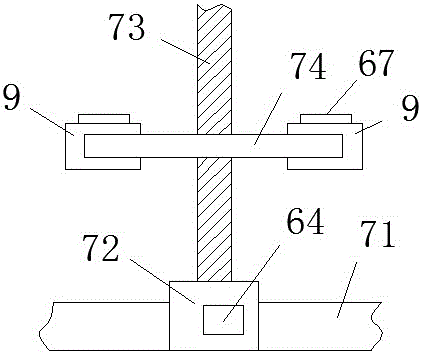

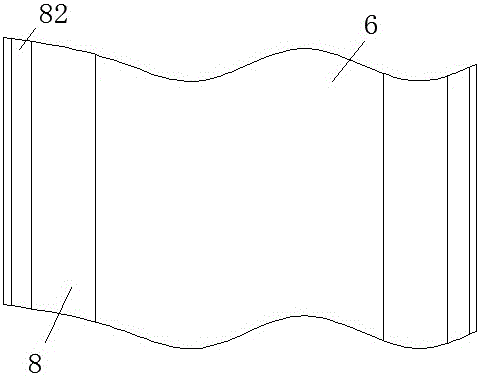

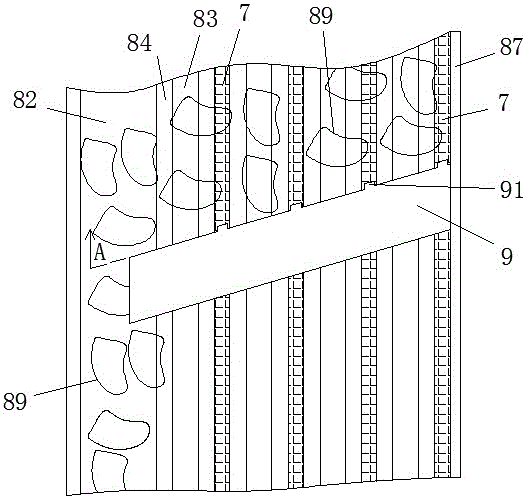

[0012] refer to Figure 1-4 , according to an embodiment of a cleaning assembly for a bridge, comprising: respectively installed on both sides of the bridge pavement 6 and extending along the longitudinal direction of the bridge pavement 6 for collecting gravel 89 on the bridge pavement 6; and A walking device 9 for cooperating with the collecting plate device 8 to push and clear gravel 89, and a driving device for driving the walking device 9 to travel longitudinally along the upper side of the collecting plate device 8, wherein the The collecting plate device 8 includes a walking guide bar 87 whose inner side is fixedly matched with the bridge pavement base to cooperate with the inner end surface of the walking device 9 to guide its walking direction. In the accommodation groove 82 for accommodating the collected crushed stones 89, the collecting plate device 8 is provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com