Column Flange Post-tensioned Steel and Concrete Partial Composite Frame-Steel Plate Shear Wall Structure

A steel plate shear wall and post-tensioning technology, applied to walls, building components, building structures, etc., can solve problems such as loss of strong anchor frame, limited range of constraints, large residual stress and residual deformation, etc., to improve bearing capacity And anti-seismic hysteresis performance, high safety and reliability, convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

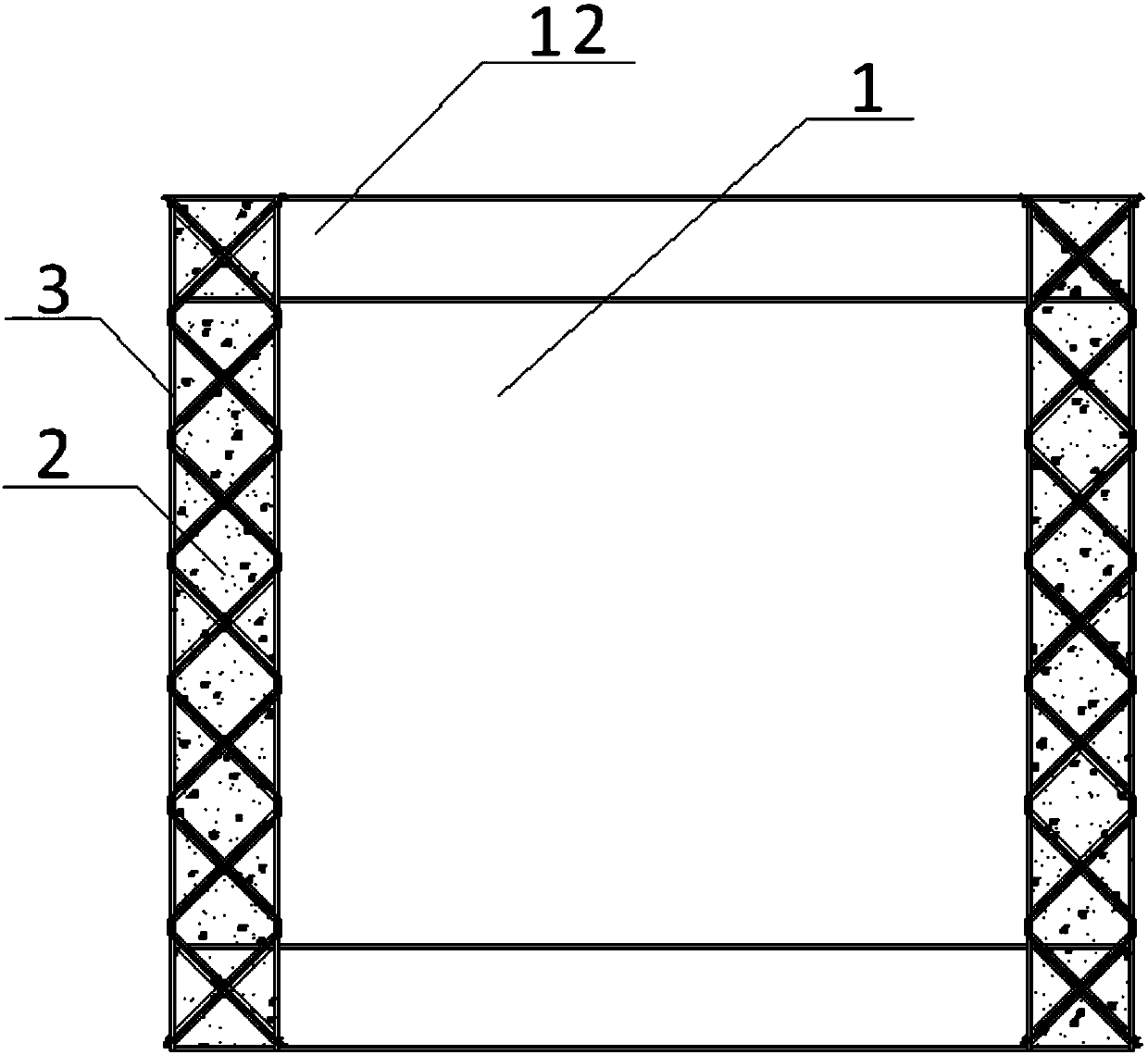

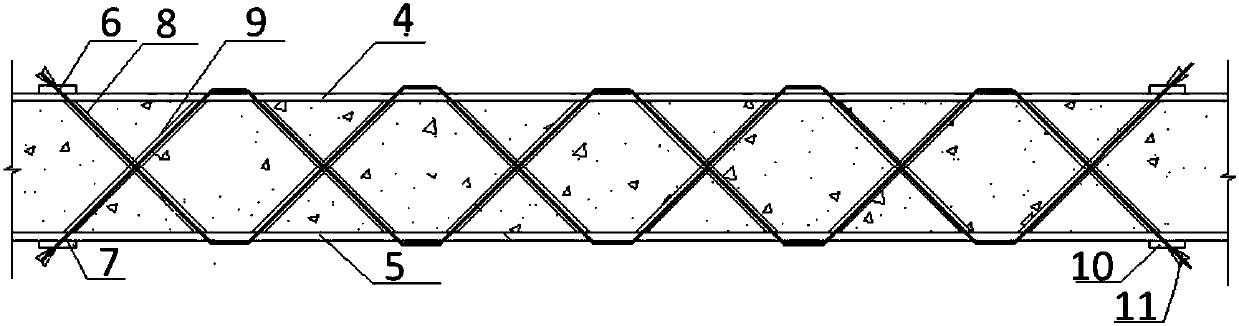

[0027] refer to figure 1 and figure 2According to the present invention, the frame-steel plate shear wall structure composed of post-tensioned steel and concrete part of the column flange includes the inner filling steel plate wall 1, the column H-shaped steel 3, the beam H-shaped steel 12, the first steel wire 6, and the second steel wire 7 , a number of first steel sleeves 8 and a number of second steel sleeves 9, the column H-shaped steel 3 is fixed on the side of the inner filling steel plate wall 1, the beam H-shaped steel 12 is fixed on the top surface of the inner filling steel plate wall 1; the column H-shaped steel 3 It consists of the first flange 4, the second flange 5 and the web, wherein the two ends of the web are respectively connected to the middle of the side of the first flange 4 and the middle of the side of the second flange 5; the first flange 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com