Packer

A packer and rubber cylinder technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problem that the packer cannot be used for bidirectional pressure bearing, etc., and achieve a large expansion ratio and reliable sealing , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

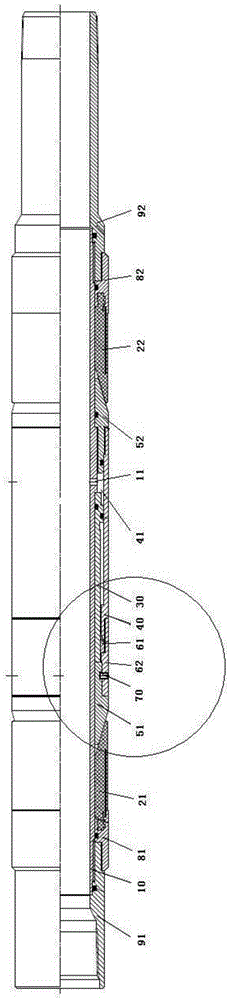

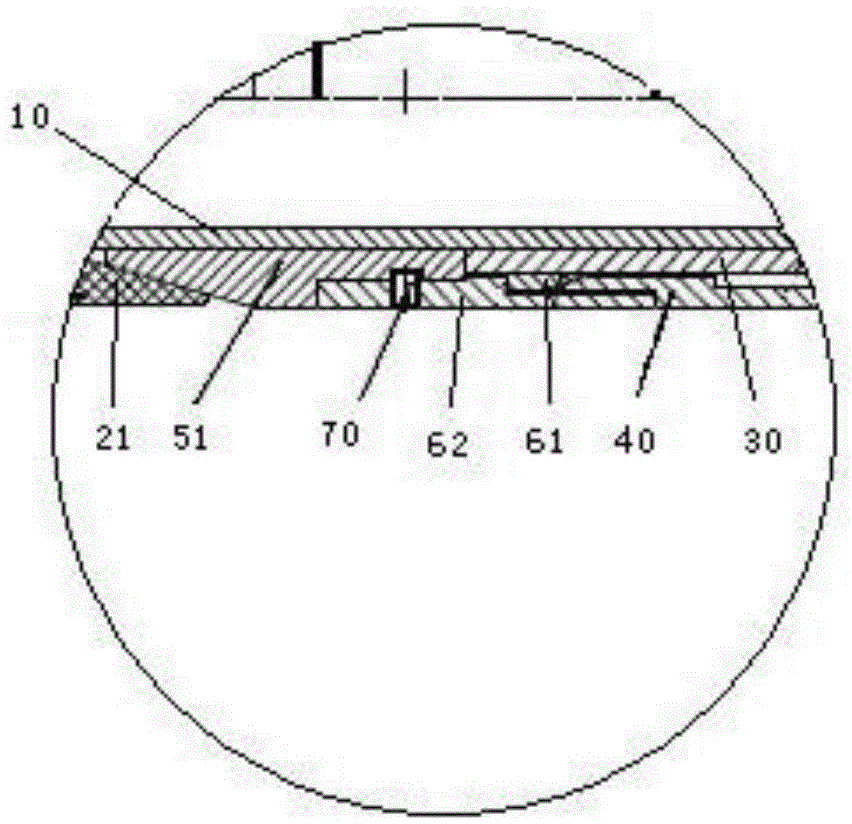

[0021] The present invention provides a packer, such as figure 1 with 2 As shown, the packer includes: a central pipe 10, including a central cavity; a first rubber cylinder 21 and a second rubber cylinder 22, fixed on the outer wall of the central pipe 10 at intervals along the axial direction; the first rubber cylinder pushes The part 51 is sleeved on the central tube 10 and abuts against the first rubber tube 21; the second rubber tube pushing part 52 is sleeved on the central tube 10 and is in contact with the second rubber tube 22; the sleeve 40 is sleeved Located on the outside of the central tube 10 and between the first rubber cartridge 21 and the second rubber cartridge 22 , there is a sealed driving cavity between the first rubber cartrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com