Blocking tower for construction of power transmission line crossing high-speed railway and construction method

A technology for power transmission lines and high-speed railways, applied to towers, building types, buildings, etc., can solve problems that threaten the life safety of workers and passengers, large displacement of towers, damage of towers, etc., to achieve efficient construction, small construction impact, and site Effects with low space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

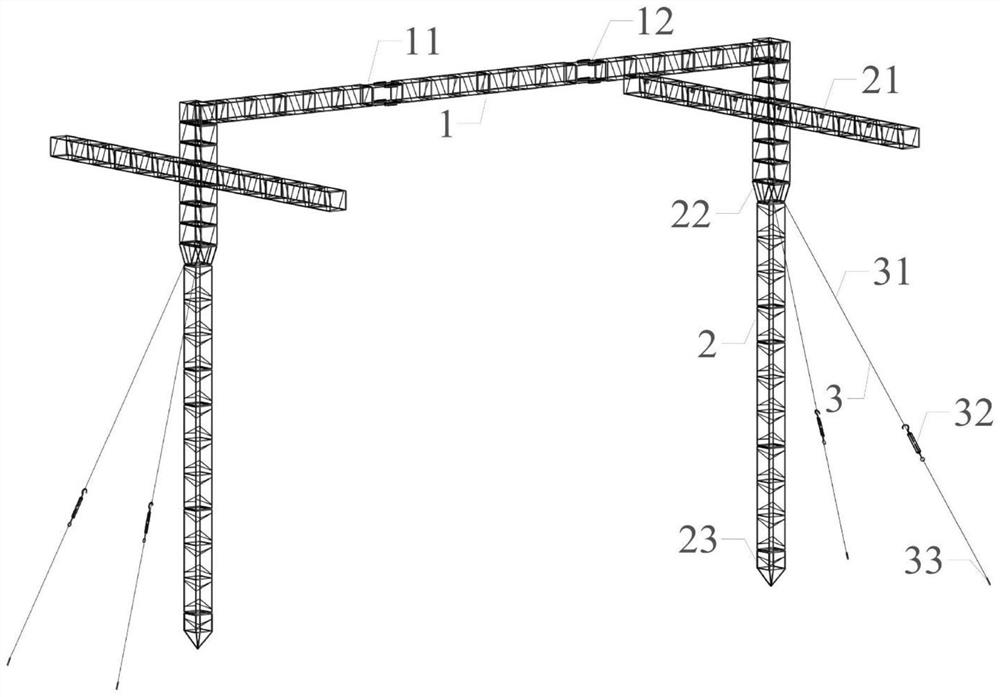

[0050] Such as figure 1 As shown, this embodiment is suitable for areas with certain loads and limited construction space. This kind of small-space power transmission line spans the network-closing tower of the high-speed railway construction, including a lattice connection frame 1, a pair of towers 2 and four stay cables 3, the four stay cables are radially arranged and anchored outside the tower surface . Two stay cables 3 are symmetrically distributed on the outside of each tower and anchored to the ground, so as to ensure the symmetry of the system in space.

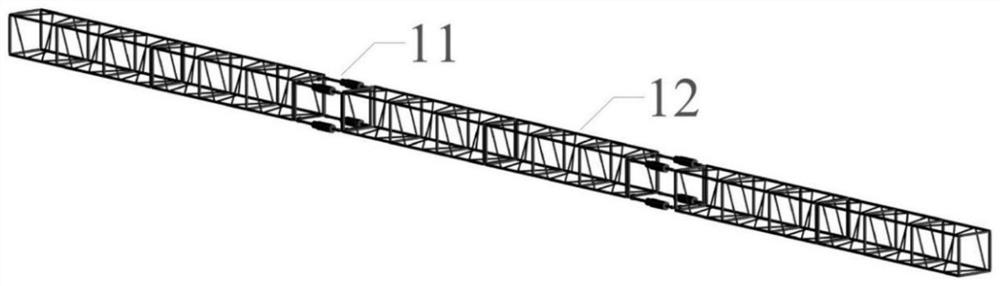

[0051] Such as figure 2 , image 3 As shown, the lattice connecting frame 1 includes a prefabricated hydraulic damper module 11 and a prefabricated cuboid truss module 12 . Among them, the prefabricated hydraulic damper module 11 includes four identical hydraulic dampers 111, each hydraulic damper has screw holes at both ends, and the dampers are connected with the square steel pipe 113 by a strut 112, and the c...

Embodiment 2

[0061] This embodiment is suitable for areas with good site natural factors and small loads. The difference between this embodiment and the preferred embodiment 1 is that the lattice connecting frames in the system are replaced by prestressed connecting cables.

[0062] The prestressed connecting cable is a prefabricated parallel steel cable bundle with eye rings, pulleys or hooks embedded at both ends. The two ends of the prestressed connecting cable are connected to the two towers, which can withstand certain dynamic loads and static loads, and have certain corrosion resistance. The prestressed connecting cables and the cables work together to maintain the overall stability of the system.

Embodiment 3

[0064] This embodiment provides a construction method for the power transmission line described in Embodiment 1 across the high-speed railway construction network sealing tower, the method mainly includes the following steps:

[0065] Determine the length of the lattice connection frame, the number of prefabricated hydraulic damper modules and the height of the tower according to the site space conditions and natural factors;

[0066] Select the size of the round steel pipe and the square steel pipe, calculate the mass of the lattice connection frame and the tower frame connected with the insulation net, and determine the pulling force of the cable;

[0067] According to the pulling force of the cable, determine the cross-sectional diameter, length, material of the cable, the specification of the nonlinear spring at the end of the cable and the anchoring position of the end of the cable;

[0068] Assemble the prefabricated truss modules into a tower, and assemble the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com