Linear compressor

A linear compressor and coil technology, applied in the field of compressors, can solve problems such as magnetic field leakage from the casing, affect the efficiency of the linear compressor, and reduce the operating efficiency of the compressor, and achieve the effects of reducing magnetic field leakage, reducing iron loss, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

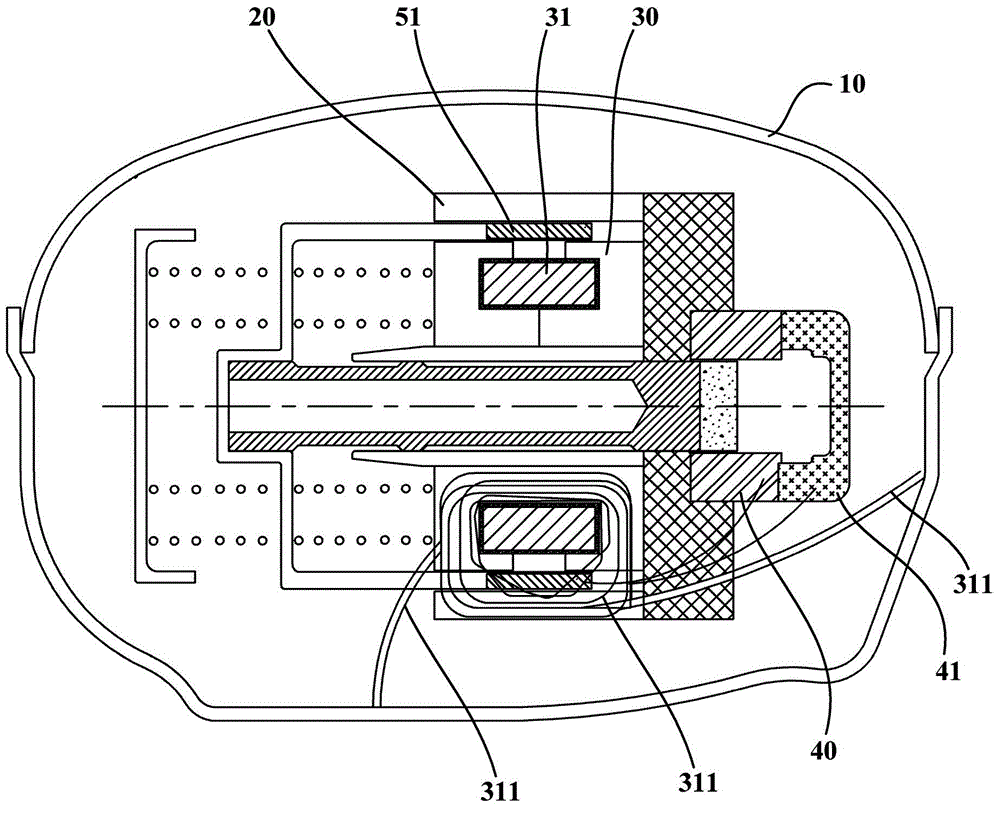

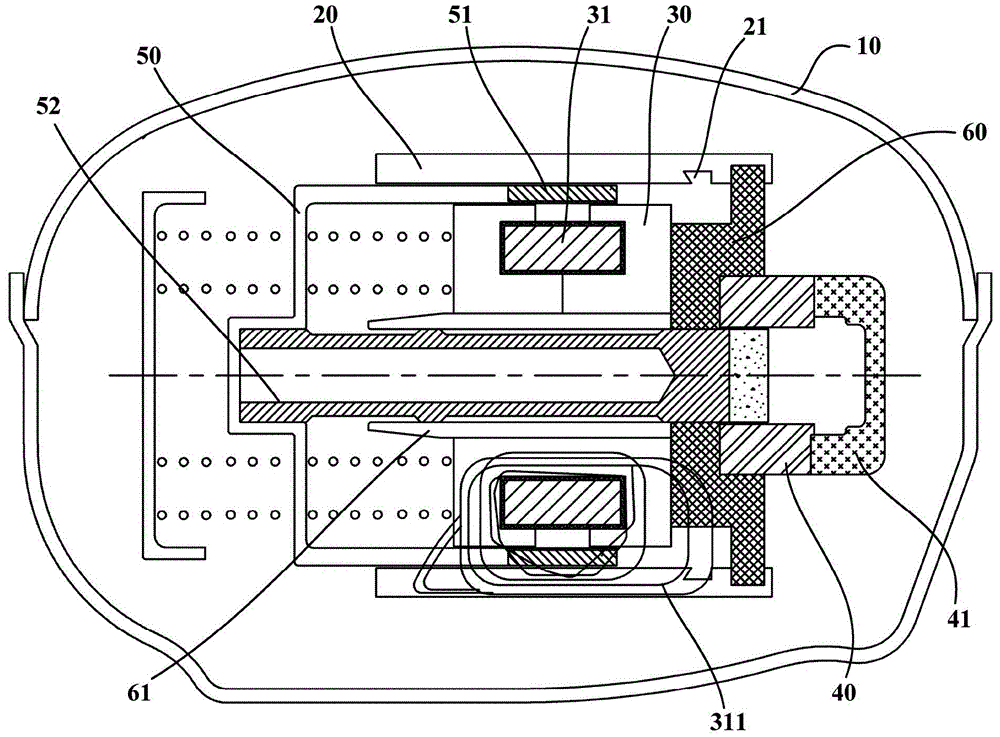

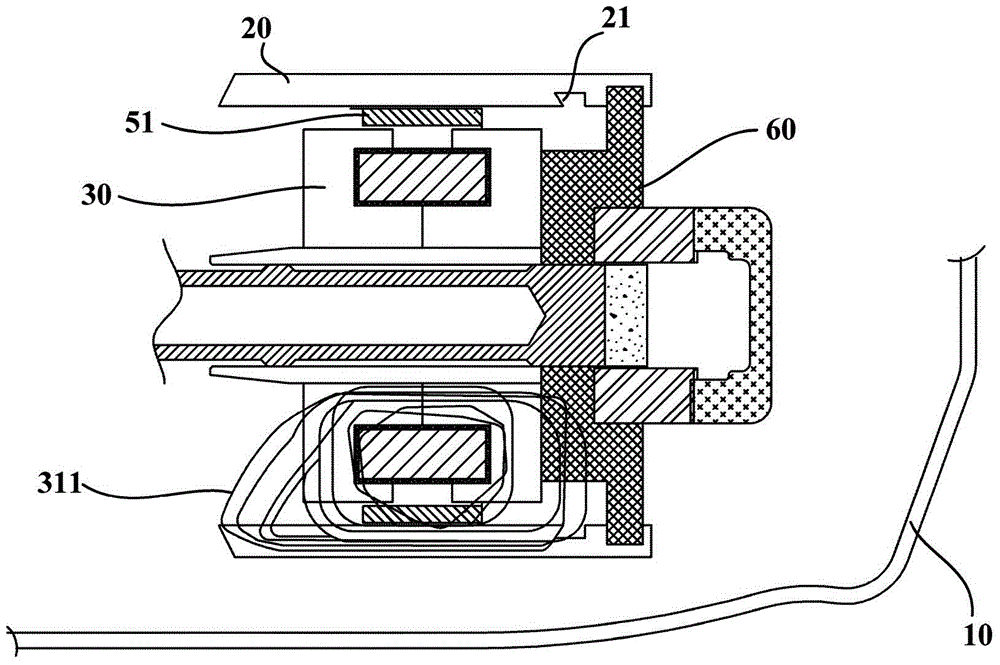

[0028] figure 2 is a schematic structural diagram of a linear compressor according to an embodiment of the present invention. like figure 2 As shown, the embodiment of the present invention provides a linear compressor, which includes: a housing 10, an outer stator 20 disposed inside the housing 10, an inner stator 30 disposed radially inside the outer stator 20 with a predetermined gap, a cylinder 40, Cylinder head 41 , mover assembly 50 , front flange 60 and sleeve 61 .

[0029] The mover assembly 50 includes: a mover bracket, a permanent magnet 51 installed on the mover bracket and extending into the gap between the inner stator 30 and the outer stator 20, a piston rod 52 installed on the mover bracket, and a piston rod installed on the piston rod 52 and extend into the piston of the cylinder 40. A coil 31 is provided on the inner stator 30 .

[0030] The front flange 60 is arranged on one axial side of the outer stator 20, specifically, it may include the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com