Flue gas backward-flow preventing coal feeding device of CFB boiler and flue gas backward-flow preventing method of device

A technology of coal feeding device and flue gas, which is applied in the field of boiler coal feeding device, can solve problems such as difficult operation, anti-flue gas reverse channeling, inconvenient maintenance, etc., and achieve the effects of low overall investment, prolonging service life and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

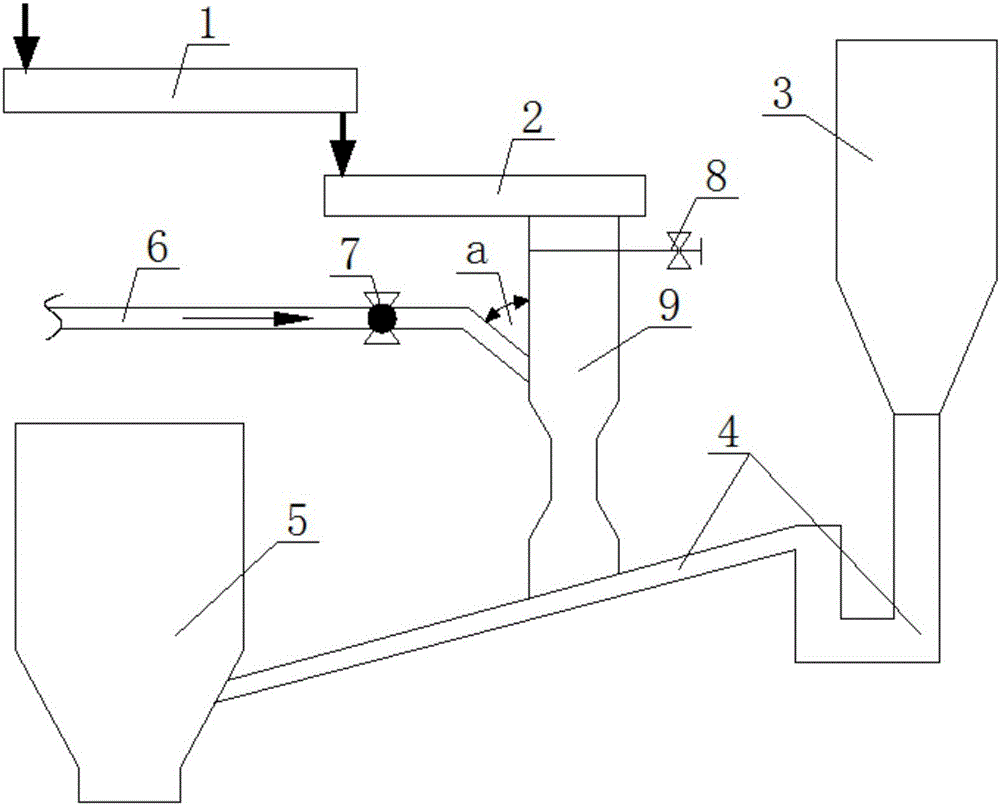

[0019] Such as figure 1 As shown, this embodiment is a coal feeding device for preventing flue gas backflow of a CFB boiler, which includes a belt coal feeder 1, a scraper coal feeder 2, a cyclone separator 3, a feeder 4, a furnace 5, a sealing Air duct 6 and Venturi coal drop pipe 9; the discharge port of the belt coal feeder 1 is connected with the feed port of the scraper coal feeder 2 through the fuel pipeline, and the belt coal feeder 1 Located above the scraper coal feeder 2; the Venturi coal drop pipe 9 is located below the scraper coal feeder 2 and the outlet of the scraper coal feeder 2 is connected to the Venturi coal drop pipe 9 The feed inlet is fixedly connected and communicated; the bottom outlet of the cyclone separator 3 is fixedly connected and communicated with the inlet of the feeder 4; the outlet of the feeder 4 is fixedly connected with the front and rear walls of the cone section of the furnace 5 and communicated; the outlet of the Venturi coal drop pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com