Damping paint sample preparation mold

A technology for making sample molds and damping coatings, which is applied in the direction of sampling, analyzing materials, and preparing test samples. It can solve problems such as easy loosening, inability to flexibly adjust the size, and inability to firmly combine double cross fittings, etc., to achieve Low production cost, simple design, affordable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention are described in detail as follows:

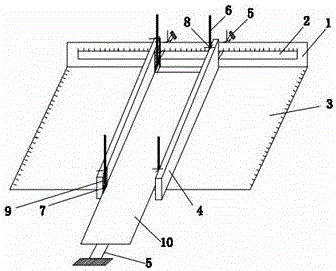

[0016] In this example, see figure 1 , a kind of damping paint sample preparation mold, which is movably assembled by a fixed plate 1, a bottom plate 3 and a slide plate 4 arranged orthogonally to each other, the bottom plate 3 is used horizontally, wherein the fixed plate 1 and the bottom plate 3 are vertically arranged and fixedly connected, and the fixed plate 1 and the bottom plate 3 are provided with a scale, the fixed plate 1 is provided with a chute 2, the extension direction of the chute 2 is parallel to the plane of the bottom plate 3, the length direction of the scale on the fixed plate 1 is parallel to the chute 2, fixed The extension direction of the scale on the plate 1 is perpendicular to the extension direction of the scale on the base plate 3, and the two symmetrically arranged slide plates 4 are respectively perpendicular to the fixed plate 1 and the base plate 3 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com