High-speed microscopic defect review method

A defect, high-speed technology, applied in the field of high-speed micro-defect review, can solve the problems of unstable focus, sensor vibration, etc., to achieve the effect of shortening time and high efficiency of review and image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

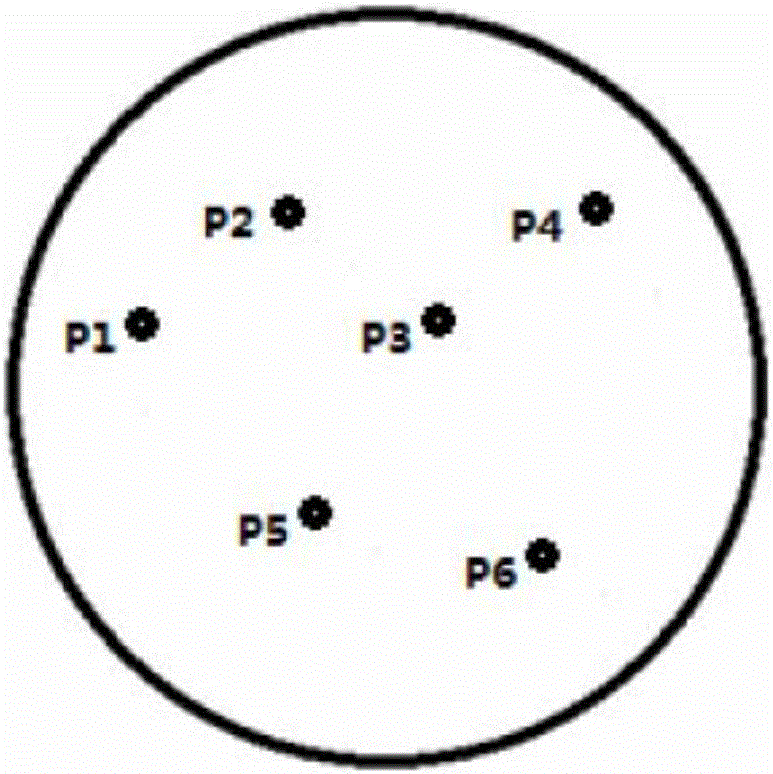

[0018] Use a line scan camera (or an area scan camera with a strobe) to perform low-magnification (1x-5x) image scanning to find the position of the defect on the surface of the inspected object (such as: wafer, flat glass or biomedical slice).

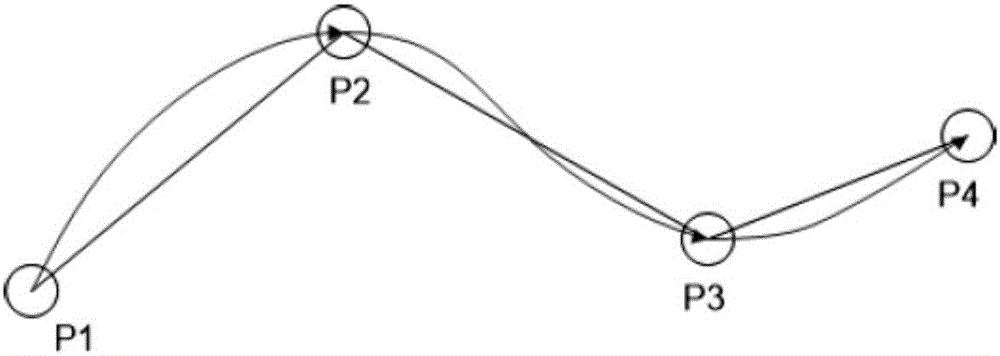

[0019] Such as figure 2 As shown, the defect points on the product are connected into a curve; for example, the four defect points P1, P2, P3, and P4 are connected into a curve in turn, and the camera passes through the four defect points of P1, P2, P3, and P4 along the curve in turn. Take high-speed photography.

[0020] A high-speed area scan camera (CCD or CMOS sensor) equipped with a high-magnification (20x-50x) microscope lens moves at a constant speed along the curve formed by the defect points, and the camera's auto-focus is always on; when ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com