Assembly line balance method drawing complexity into consideration

A complex and assembly line technology, applied in the direction of genetic rules, constraint-based CAD, special data processing applications, etc., can solve the problems of high probability of unqualified products, high complexity, and heavy burden, so as to improve efficiency, The effect of complexity balance and reduction of production cycle disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

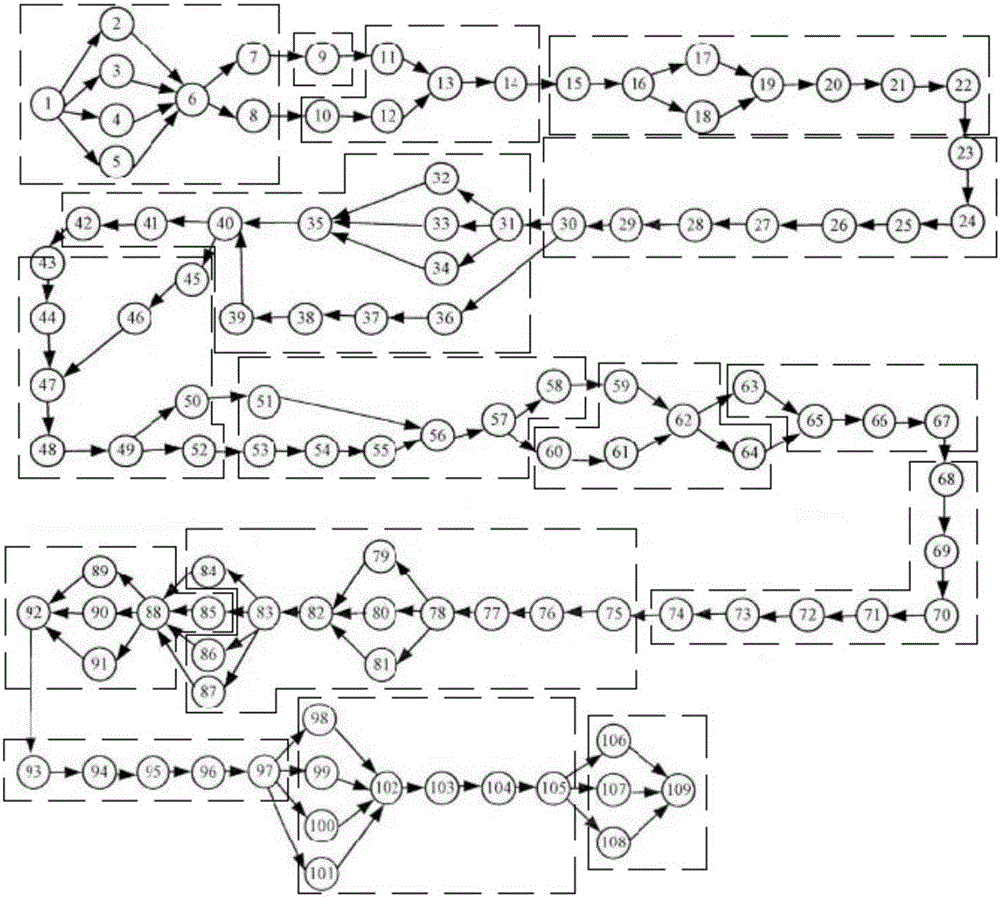

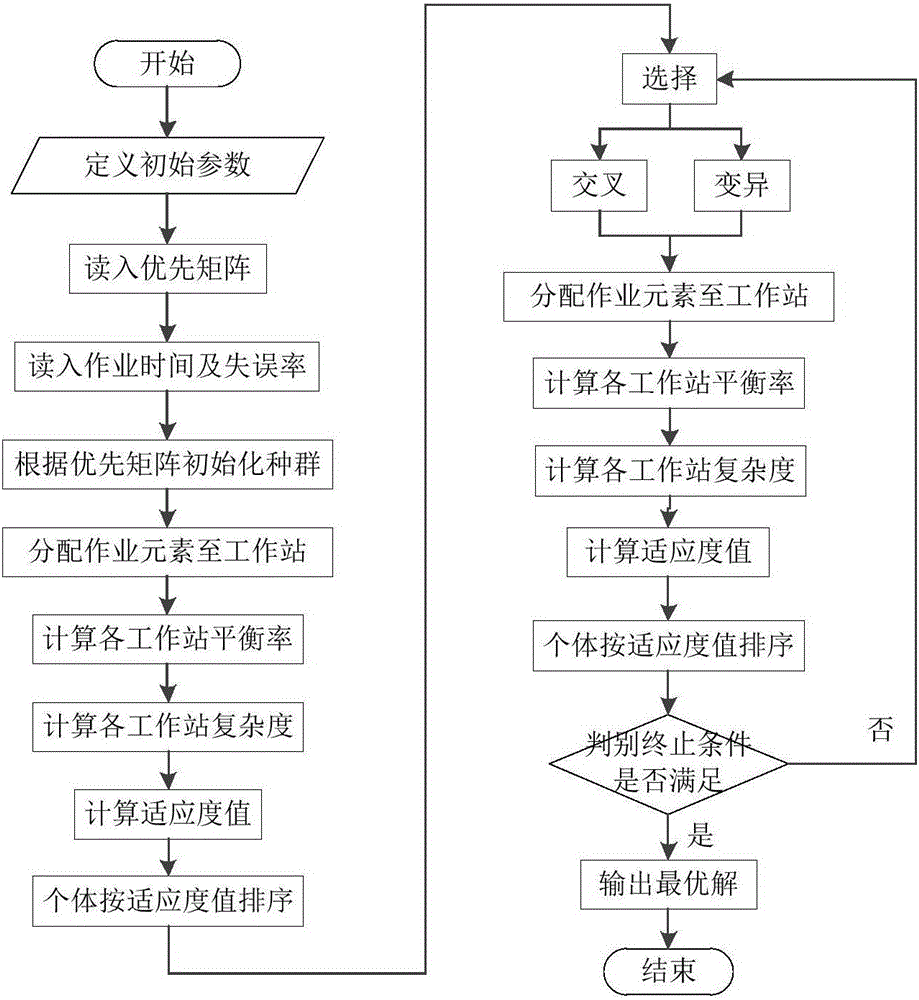

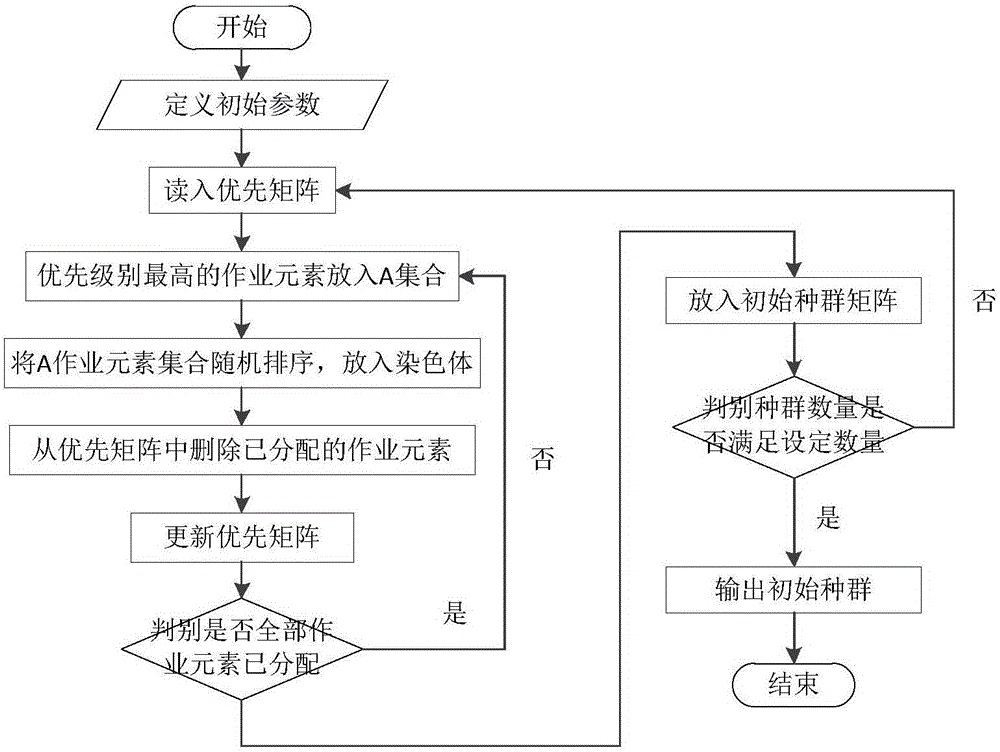

[0070] The present invention uses MATLAB to compile executable programs according to the contents of the invention. Its effect is illustrated by an example of a passenger car assembly line of a car company. The example contains 109 job elements, the corresponding job time and error rate are shown in Table 1, and the priority relationship between job elements is as follows figure 1 As shown, the number represents the sequence number of the operation element, and the arrow connects two operation elements. The operation element pointed by the arrow is the subsequent operation element, and the operation element before the arrow is the immediate predecessor operation element. Generate a priority matrix based on the priority relationship graph, which can be read into an executable program for calculation. The task of the invention is to control the tempo of the whole line within 22s according to the production plan, seek the maximum balance rate and balance the complexity of each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com