Mobile positioning mechanism for photovoltaic cell interconnected electrode

A technology of photovoltaic cells and interconnected electrodes, applied in the field of fixtures, can solve the problems of easy bending and swinging, easy bending deformation, reduction in width and thickness, etc., and achieve the effects of strong applicability, high stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

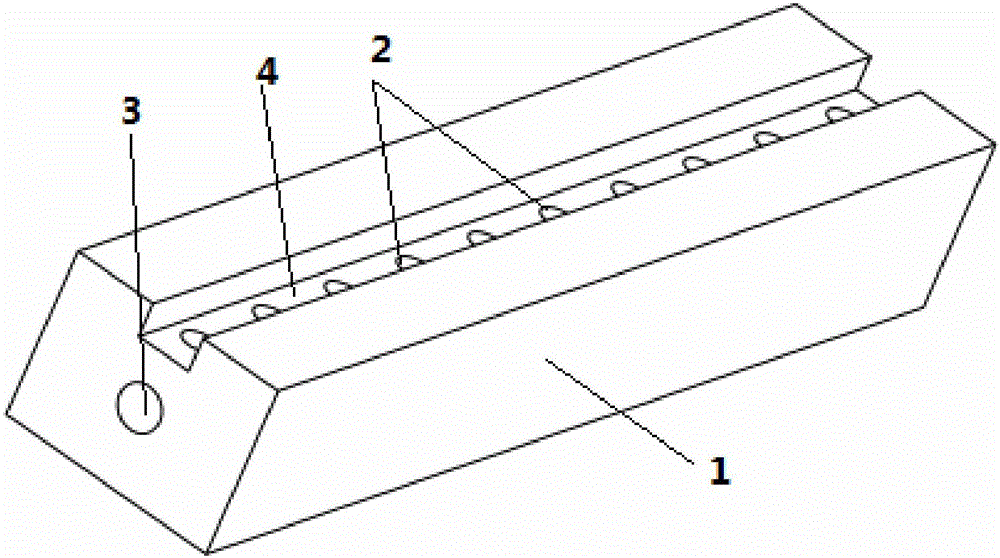

[0028] Embodiment 1: A mobile positioning mechanism (grabbing, moving, aligning, and positioning of flat ribbons) for interconnecting electrodes of photovoltaic cells.

[0029] See attached figure 1 ~ attached Image 6 As shown, processing as figure 1 The structure of the upper positioning body 1 shown makes the upper limit groove 4 wide 1.6mm, the groove depth 1.5mm, the cross section of the upper limit groove 4 is rectangular, the diameter of the upper suction hole 2 is 1mm, and the distance is 5mm.

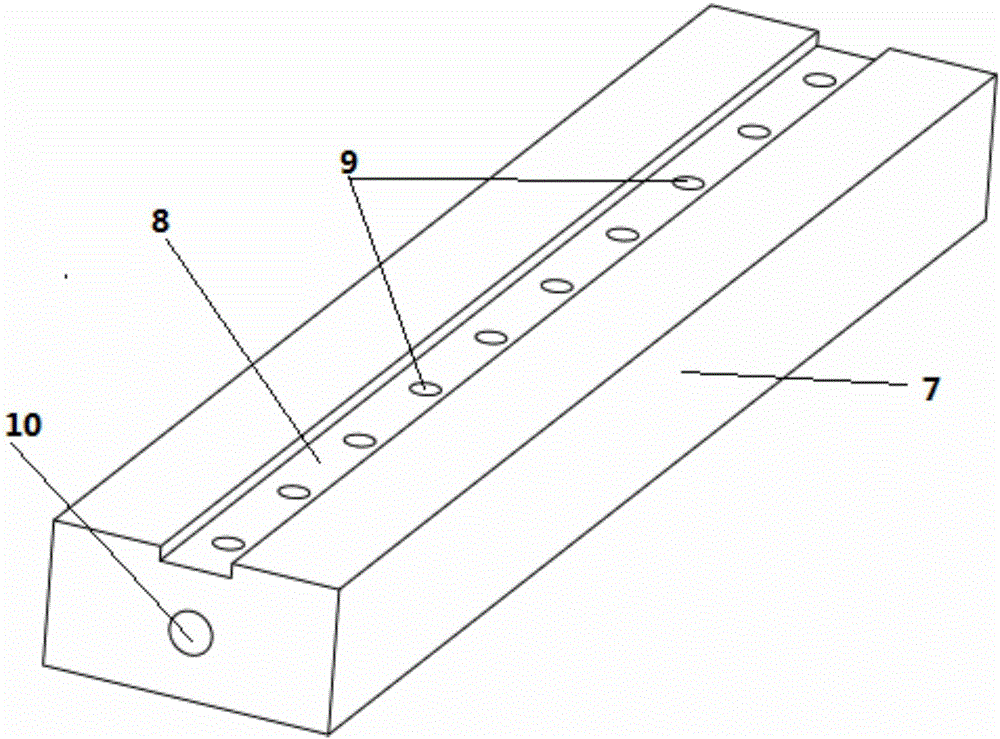

[0030] processed as figure 2 The structure of the lower positioning body 7 is shown, the lower limit groove 8 is 1.6mm wide, the groove depth is 0.15mm, and the lower suction hole 9 has a diameter of 1.0mm and a spacing of 5mm.

[0031] Firstly, the flat welding ribbon 5 with a width of 1.5mm and a thickness of 0.25mm is cut straight and cut into a fixed length of 120mm, and suction is generated through the upper air hole 3, and the aforementioned welding ribbon is adsorbed...

Embodiment 2

[0033] Embodiment 2: A mobile positioning mechanism for photovoltaic cell interconnection electrodes (grabbing and moving of special-shaped cross-section welding ribbons).

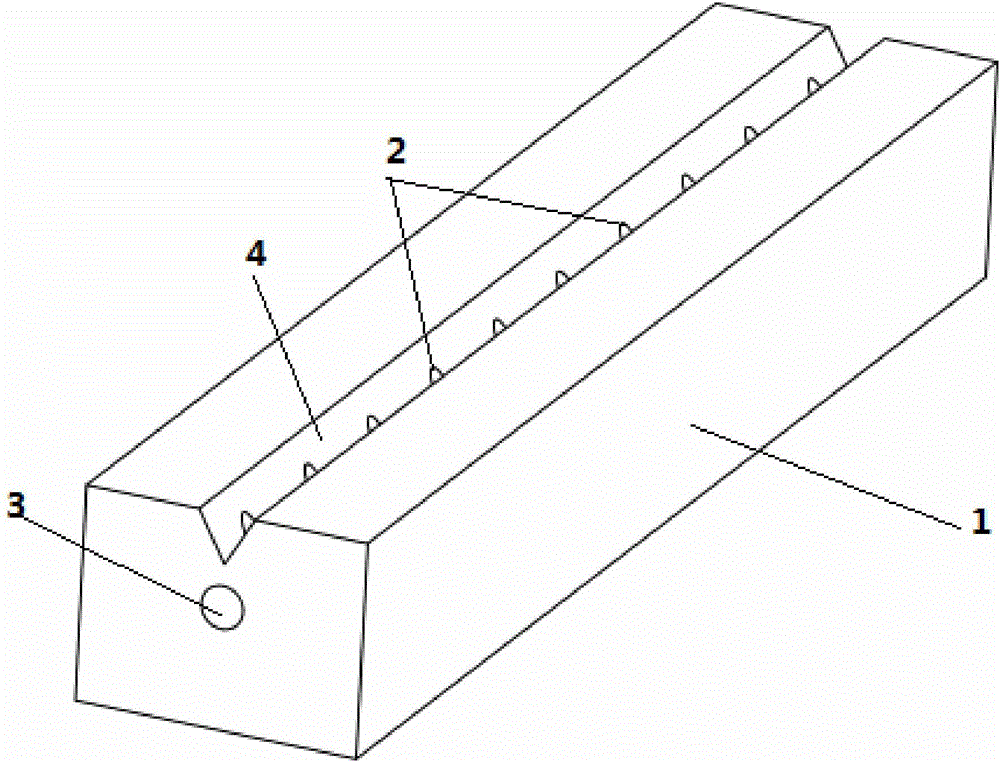

[0034] The top of the upper limit slot can be processed with a triangular section or a circular arc section respectively. Put the straighter triangular welding strip 6 or round welding strip 11 in the limiting slot. Perform various mobile operations. This operation can realize various operations such as grasping, moving, aligning, and positioning of high-flexibility ribbons of various shapes, and has high operating precision, low cost, fast speed, high repeatability and good stability. The illustrated structure in the present invention that needs to be explained is not the whole content of the structure of the present invention, and changes such as increasing and decreasing modifications to the structural shape of the present invention and dimensions such as grooves and holes are all within the protection ...

Embodiment 3

[0035] Embodiment 3: A mobile positioning mechanism for interconnecting electrodes of photovoltaic cells.

[0036] See attached figure 1 ~ attached Image 6 As shown, a mobile positioning mechanism for interconnected electrodes of photovoltaic cells includes a lower positioning body 7 and an upper positioning body 1. The lower positioning body 7 includes a lower limit groove 8, a lower suction hole 9 and a lower air hole 10. The lower limit The positioning slot is provided on the lower positioning body, and a lower suction hole is opened in the lower positioning slot, and the lower suction hole communicates with the lower air hole opened in the lower positioning body, and the depth of the lower limiting slot is smaller than that of the photovoltaic The height of the flat ribbon of the battery; the upper positioning body 1 includes an upper limit groove 4, an upper suction hole 2 and an upper air hole 3, the upper limit groove is set on the upper positioning body, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com