A heliostat structure and its installation method

The technology of heliostat and square flange is applied in the field of solar power generation, which can solve the problems of time-consuming and laborious installation, and achieve the effects of improving installation accuracy, speeding up installation operation time, and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail.

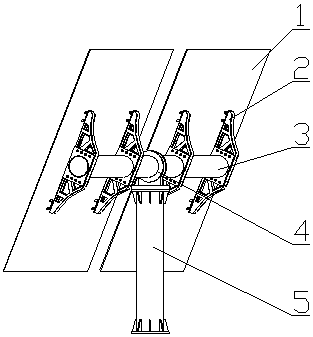

[0028] The heliostat structure of the present invention is as figure 1 shown. The heliostat mainly includes a reflector assembly 1, a support arm 2, a torque tube support assembly 3, a drive system 4, and a column 5. The drive system 4 is arranged on the top of the column 5, and the drive system 4 drives the torque tube support assembly 3 to move and supports The arm 2 is evenly fixed on the torque tube support assembly 3 , and the reflector assembly 1 is fixedly connected to the support arm 2 .

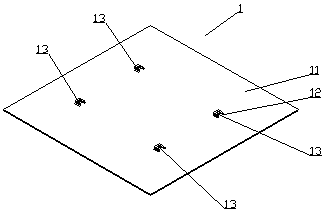

[0029] The structure of mirror assembly 1 is as figure 2 As shown, the mirror assembly 1 is composed of a mirror 11 , an adhesive 12 , and a fastener 13 for the mirror.

[0030] The reflector assembly 1 in the heliostat can consist of one or several.

[0031] The reflector 11 and the reflector fastener 13 are adhered together by the adhesive 12 .

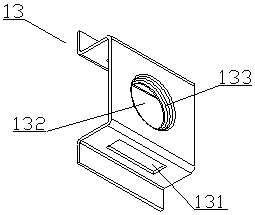

[0032] The structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com