Polymer light emitting diode structure, manufacturing method, display substrate, and display device

A technology of light-emitting diodes and polymers, applied in the directions of organic semiconductor devices, semiconductor devices, electrical components, etc., can solve the problems of adverse effects on the service life of sub-pixels and lighting quality, non-uniform current flowing through thin films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order for those skilled in the art to better understand the technical solutions of the present invention, a display panel and a display device provided by the present invention will be further described in detail below with reference to the drawings and specific embodiments. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0032] The invention provides a polymer (PLED) light emitting diode structure.

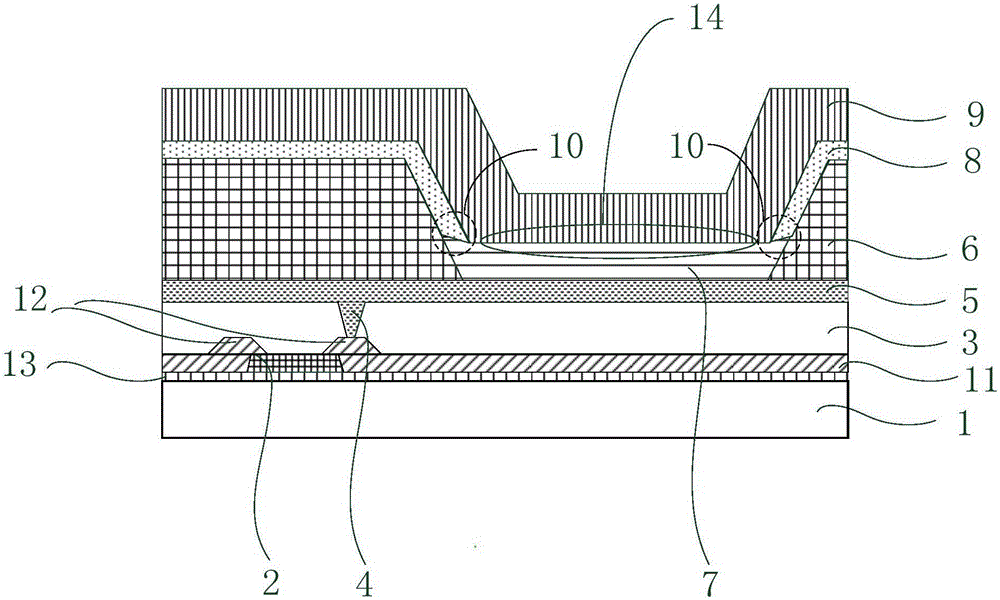

[0033] figure 1 A cross-sectional view of an exemplary PLED structure is shown. The PLED structure may include a substrate 1, an isolation layer 13, a thin film transistor array (TFT) layer 2, a gate insulating layer 11, a planarization layer 3, a via hole 4, an anode layer 5, a pixel definition layer 6, a light emitting layer 7, A sub-pixel blocking layer 8, and a cathode layer 9. For illustrative purposes, figure 1 Only the source and drain of one TFT of said TFT layer 2 are shown, indicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com