Cup body identification method for food processor

A technology of a food processing machine and an identification method, which is applied in the field of cup body identification of food processing machines, can solve the problems that cannot be realized according to the user's instructions, cannot realize heating, user troubles, etc., achieves convenient operation, and reduces the interference between signals , Accurate signal transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

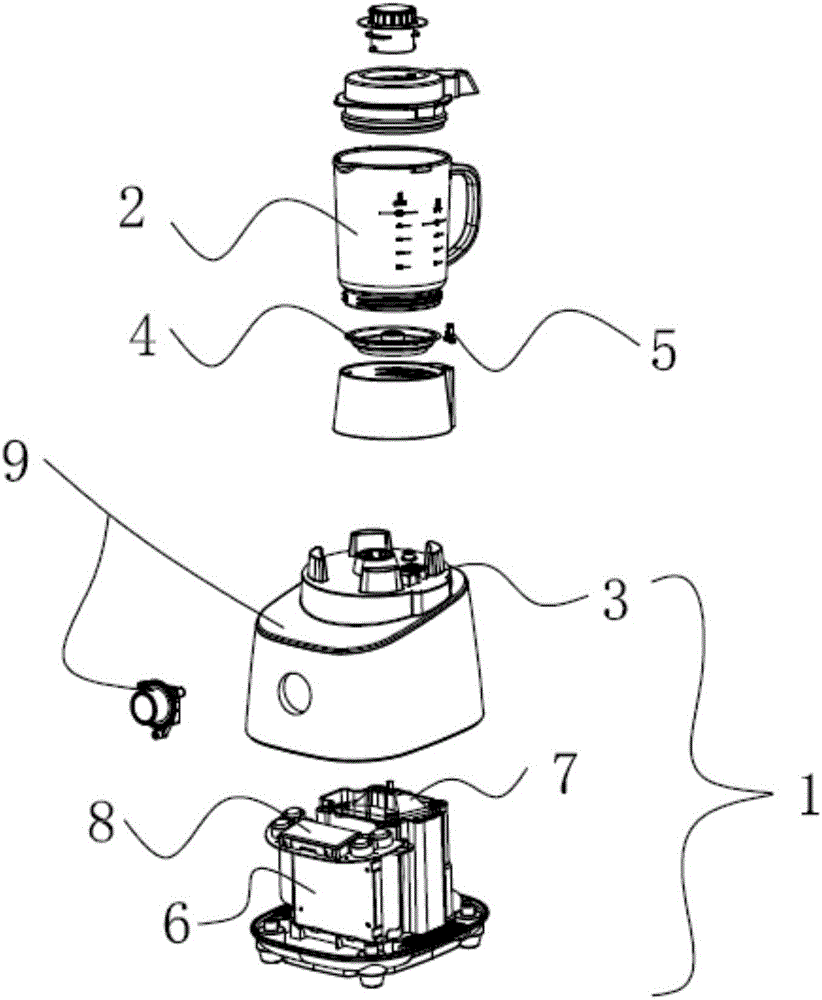

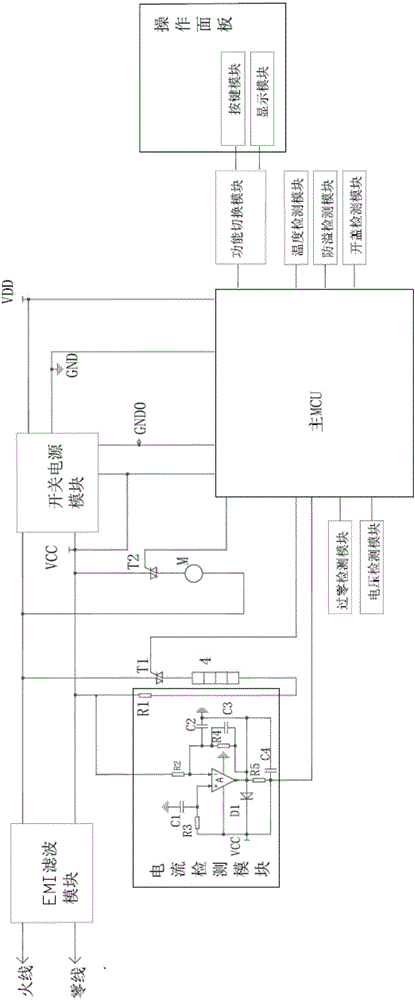

[0059] See attached Figure 4-5 The difference between Embodiment 2 and Embodiment 1 is that the central processing unit includes a master MCU and a slave MCU. The master MCU and the slave MCU perform signal transmission through photoelectric coupling, and the isolation of strong and weak electricity is realized through the setting of the master and slave MCUs. In this embodiment, in order to make the isolation effect better, the main MCU and the function switching module are arranged on the main control board 8, and the slave MCU and the current detection unit are arranged on the power supply board 6, and the detection resistor of the current detection unit R1 is set in the main circuit, and the resistance is preferably constantan wire or manganese copper wire of 10mΩ-100mΩ. When the thyristor T1 is turned on and T2 is turned off, the heating circuit is turned on, and the current flows through the resistor R1. The resistance is large and the current change is small. Therefore...

Embodiment 3

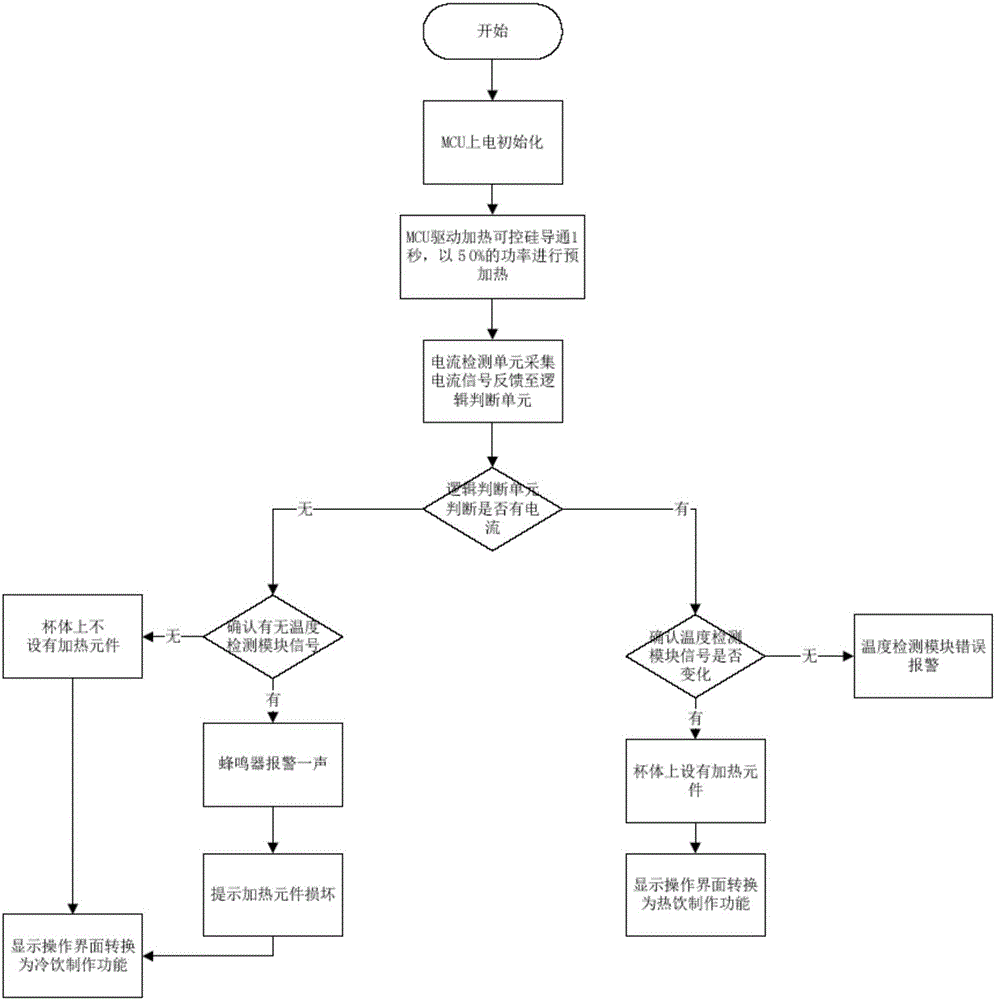

[0066] See attached Figure 6 In this embodiment, the difference between the third embodiment and the first embodiment is that the heating circuit does not have a current detection unit, but the temperature detection module on the cup body and the cup body identification module are electrically connected through the lower coupler 4, according to The change of the temperature detection module judges the presence or absence of the heating element.

[0067] In this embodiment, the output terminal of the MCU drives the thyristor T1 to conduct heating with 100% power for 2 seconds. If the cup body is equipped with a heating element, after the cup body is heated, the temperature of the temperature detection module will change and will The result is fed back to the MCU, and the main MCU judges the presence or absence of the heating element according to the feedback result of the temperature detection module. If it is judged that the cup body has a heating element, it will switch to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com