Annular numerical control automatic hole manufacturing system used for butt joint assembly of airplane body

An aircraft fuselage, automatic manufacturing technology, applied in aircraft parts, manufacturing tools, transportation and packaging, etc., can solve the problems of large axial force in hole making, frequent tool change processing efficiency, etc., to improve efficiency and improve the flexibility of hole making The effect of saving the trouble of frequent tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

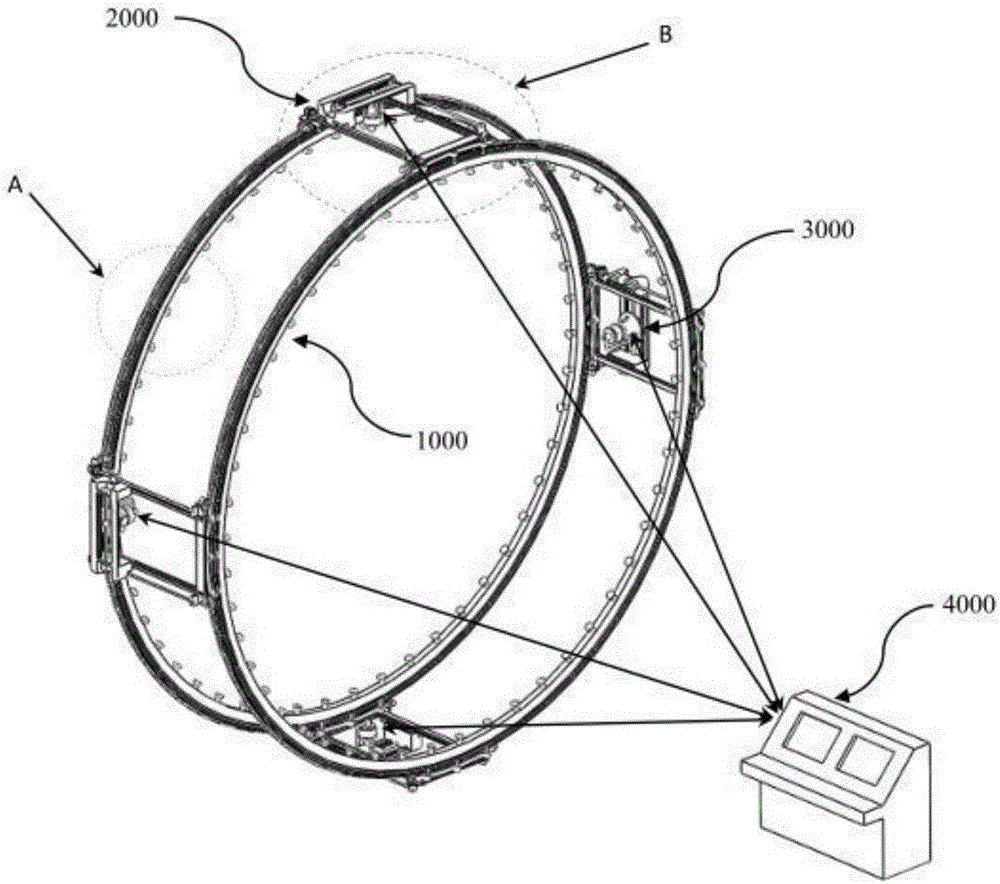

[0030] Such as figure 1 As shown, the present invention is used for the circular numerical control automatic hole-making system of aircraft fuselage butt joint assembly and comprises: two circular track assemblies 1000, four four-wheel drive carrying devices 2000 that move along two circular track assemblies 1000 and be installed on four-wheel drive carrying The automatic hole making device 3000 on the device 2000.

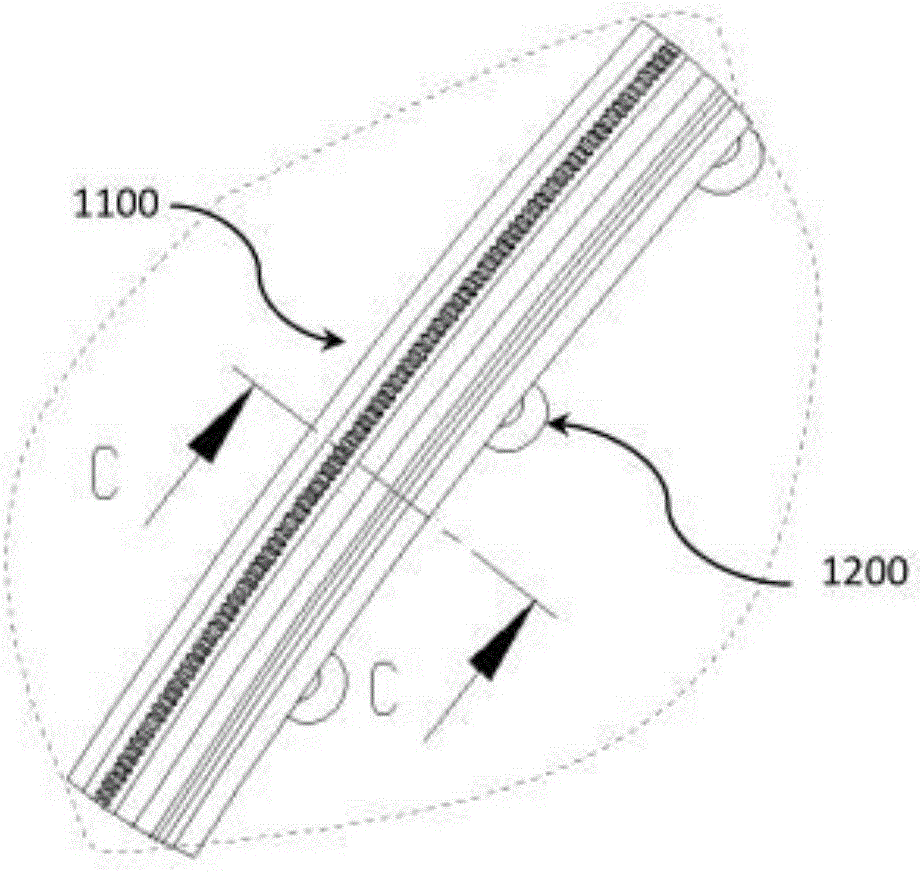

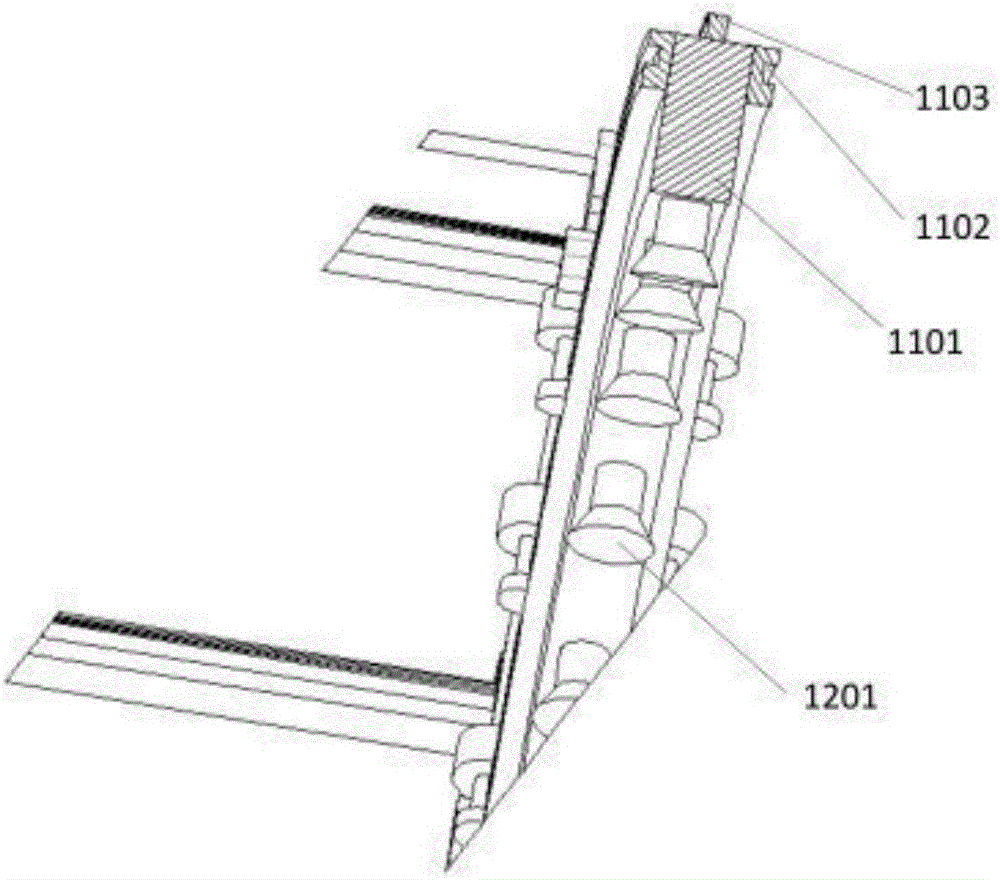

[0031] Such as figure 2 and 3 As shown, the circular rail assembly 1000 includes a flexible rail module 1100 and a vacuum chuck assembly 1200, wherein each annular rail assembly 1000 may include several flexible rail modules 1100; each flexible rail module 1100 includes a flexible rail bracket 1101, two guide slides Groove 1102 and arc-shaped flexible rack 1103; two guide chute 1102 are respectively installed on both sides of the flexible track support 1101, and the arc-shaped flexible rack 1103 is arranged on the track outer ring of the flexible track support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com