Fabrication Mold of Circular Layer Structure with Lattice Features

A ring-shaped, layer-structured technology, applied in the directions of lamination, lamination device, layered products, etc., can solve the problems such as no mold for preparing a ring-shaped sandwich structure, low yield, and inconsistent specifications of finished parts. , to achieve the effect of high yield, improved production efficiency and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

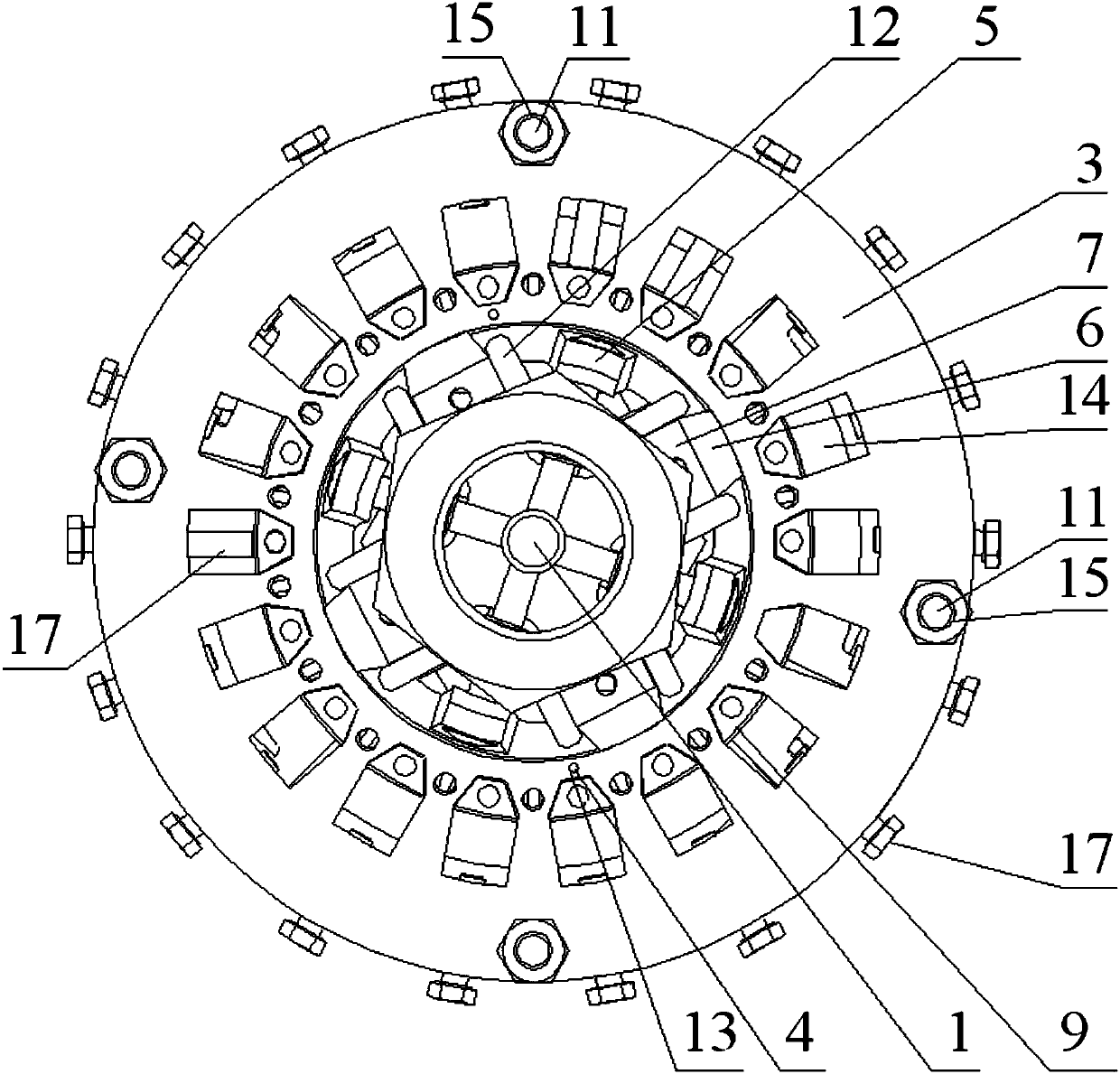

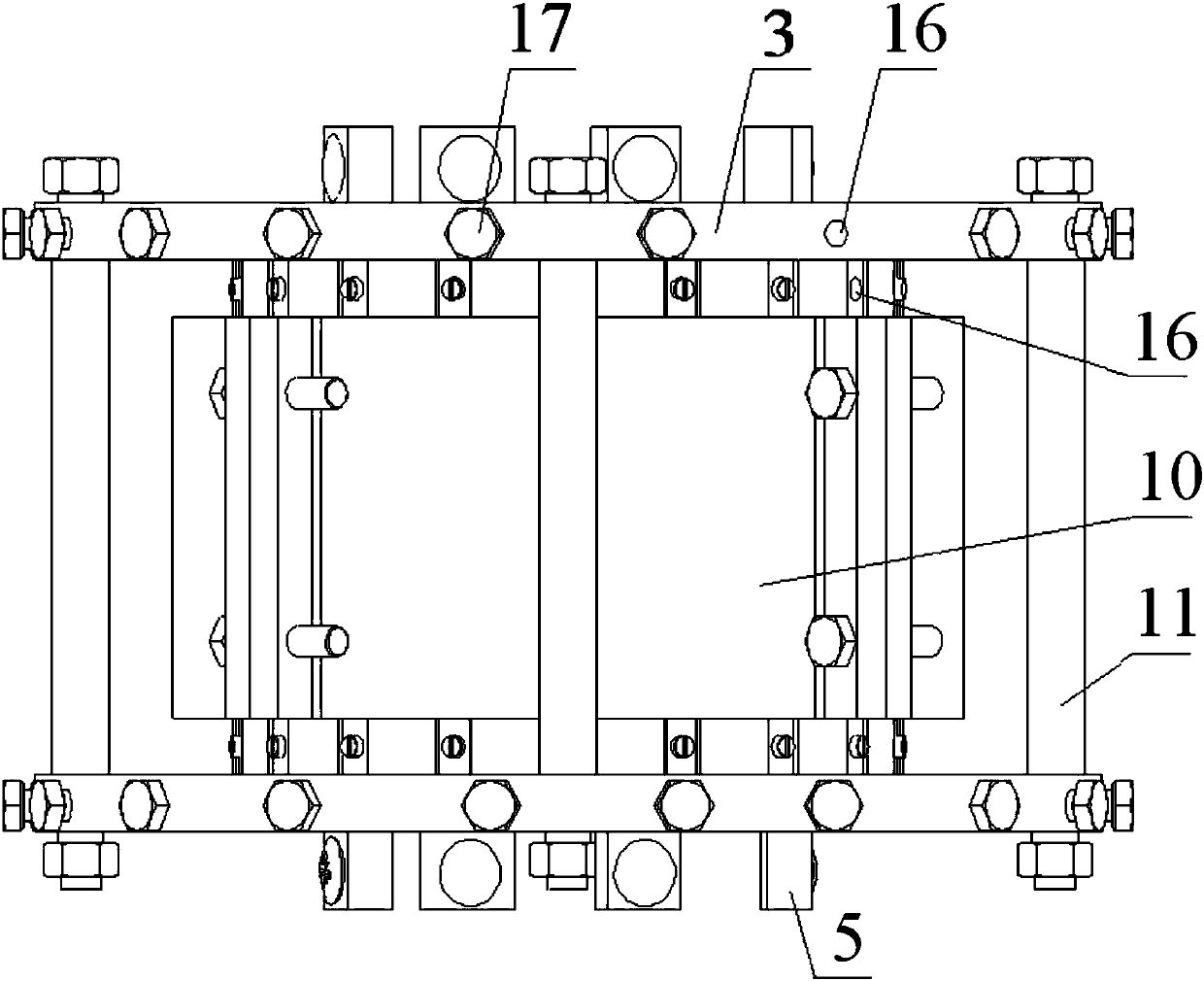

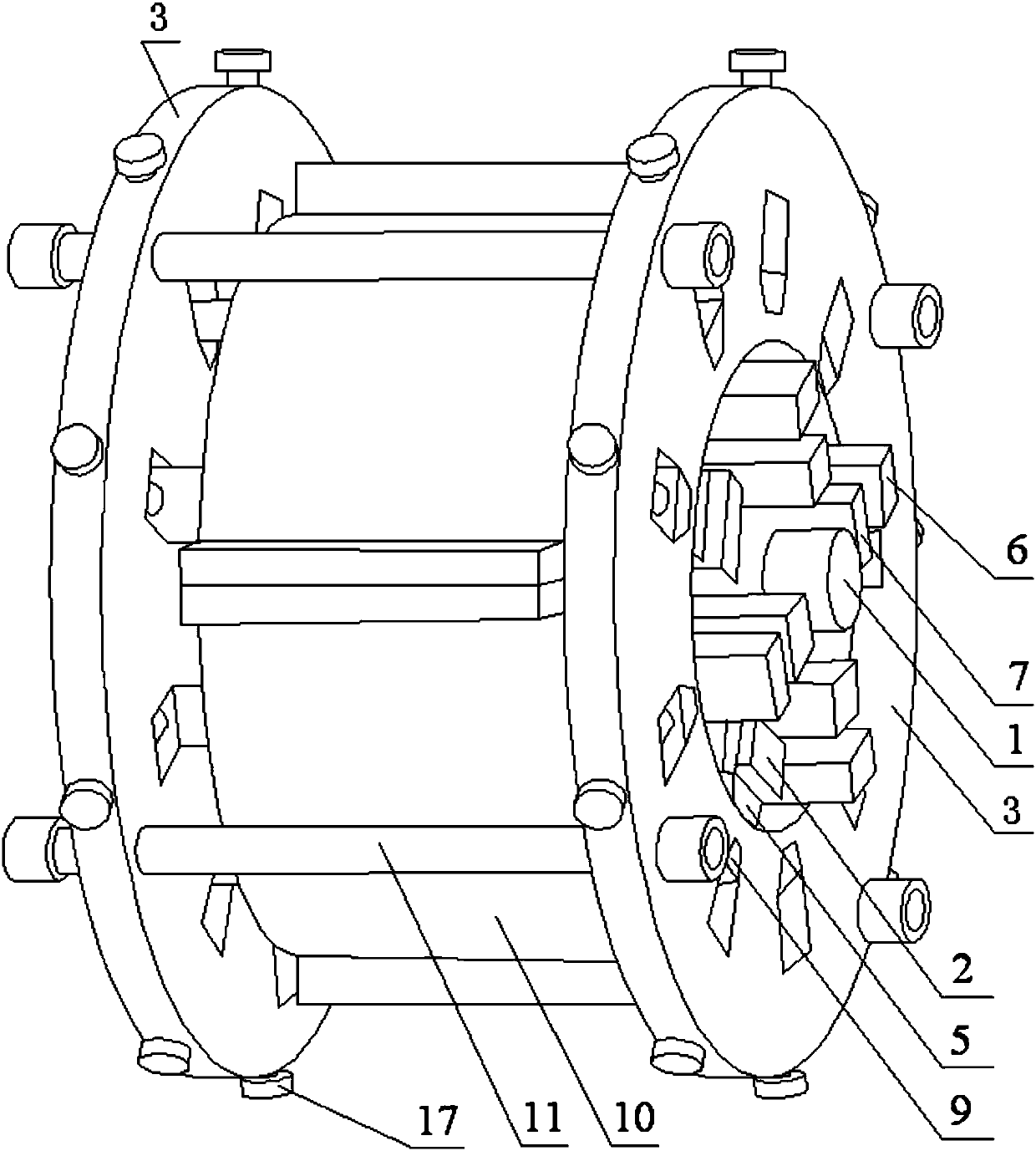

[0025] The ring-shaped layer structure with lattice characteristics of the present embodiment prepares the mould, combined with figure 1 As shown, a preparation mold with a ring-shaped layer structure with lattice characteristics, its composition includes a mandrel 1, two reducing shaft brackets 2, a group of reducing bearing pads 5, a group of reducing shaft beading 6, a A set of pads 7, a set of inner bead 8, a set of outer bead 9, a set of outer plate cylinder components 10, a set of support rods 11 and a set of adjusting screw 20;

[0026] Between the two reducer shaft brackets 2: with the mandrel 1 as the center, it includes a cylindrical layer surrounded by a set of reducer bearing pad plates 5 and a set of reducer shaft beading bars 6 arranged alternately from the inside to the outside, consisting of a set of inner A cylindrical layer surrounded by layers of beading 8 arranged in sequence, a cylindrical layer formed by a group of outer beading bars 9 arranged in sequenc...

specific Embodiment approach 2

[0030] The difference from Embodiment 1 is that in this embodiment, the ring-shaped layer structure with lattice characteristics is used to prepare the mould, each of the variable-diameter shaft brackets 2 is a ring-shaped panel, and there is a set of limit positions around the variable-diameter shaft bracket 2 plate 12, a first spacer lattice and a second spacer lattice are respectively formed between each spacer plate 12 and two adjacent spacer plates 12, and the formed first spacer lattice and second spacer lattice are Arranged alternately; wherein, the two limiting plates 12 forming the first limiting grid are arranged in parallel, and the angle between the extension lines of the two limiting plates 12 forming the second limiting grid is 90°.

specific Embodiment approach 3

[0031] The difference from Embodiment 1 or Embodiment 2 is that in this embodiment, the ring-shaped layer structure with lattice characteristics is used to prepare the mould, each of the outer bead support plates 3 is a ring-shaped panel, and the panel of the ring-shaped panel extends from the center to the surrounding area. Two positioning pin holes 13, a circle of bead holes 14 and a circle of support rod holes 15 are provided in sequence, each bead hole 14 communicates with a pressure hole 16 pointing to the center of the outer bead support plate 3, and the pressure hole 16 is screwed with an adjusting screw 20. Rotate the adjusting screw 20 to pressurize the outer bead 9 inserted in the bead hole 14 for fine adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com