Pressure regulating type waste water ratio

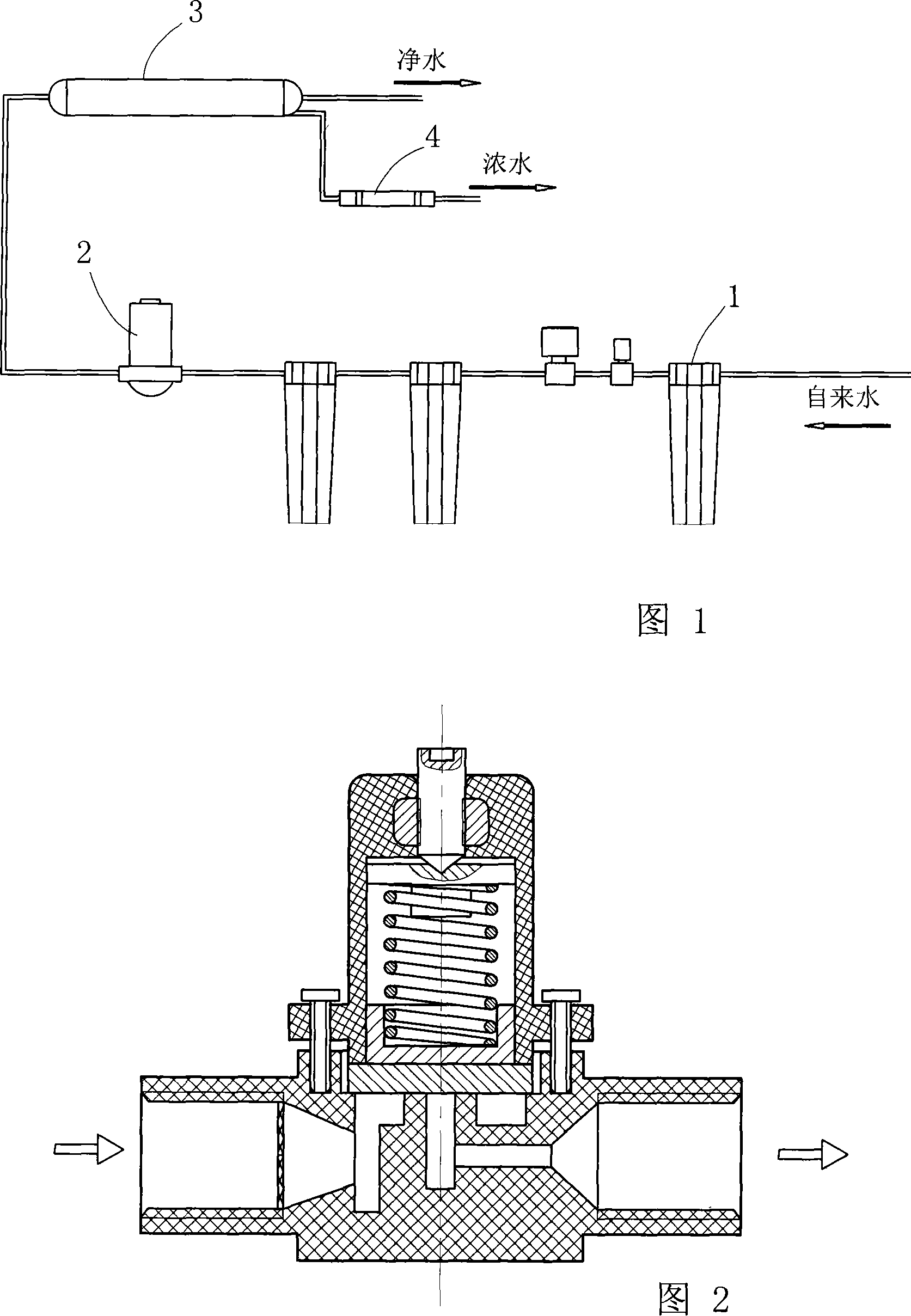

A waste water ratio and pressure regulating technology, applied in the direction of osmosis/dialysis water/sewage treatment, functional valve type, reverse osmosis, etc., can solve the problem that the working pressure of the RO membrane is difficult to stabilize, can not reach a constant or adjust the outlet pressure, and the RO membrane ruptures Ineffective water production and other issues, to achieve the effect of uniform production process and low defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

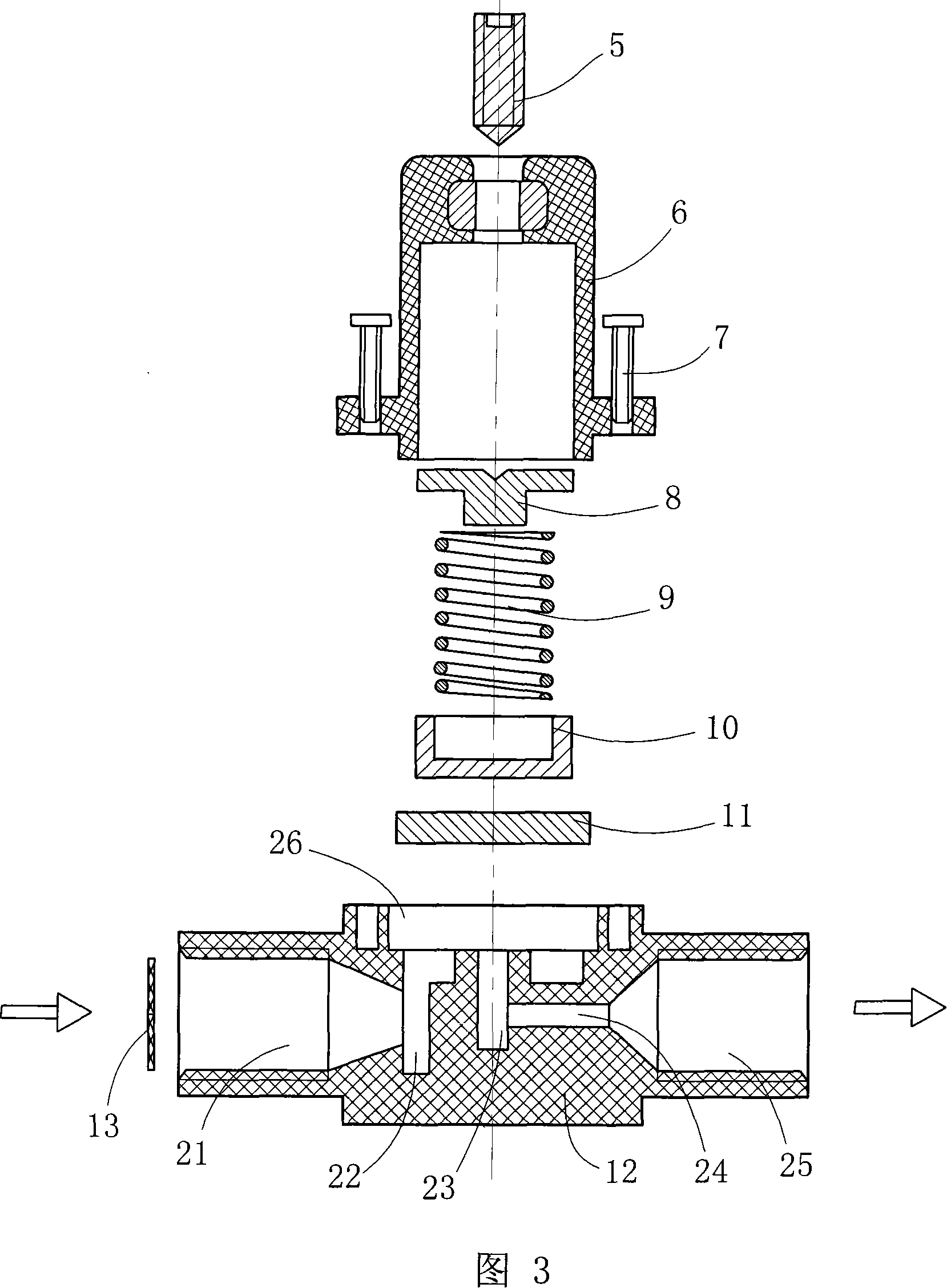

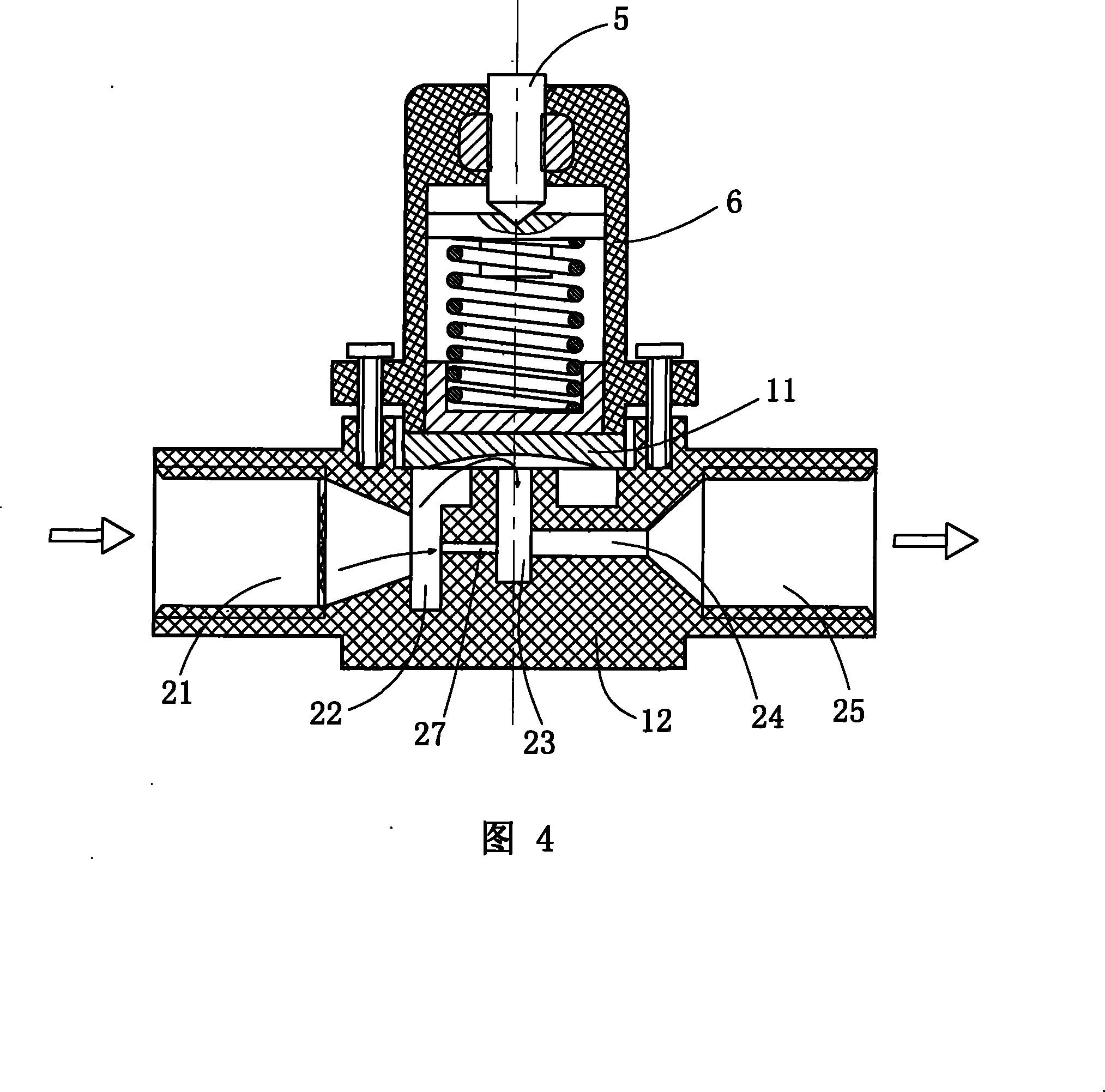

[0017] Refer to Figure 2 and Figure 3. The waste water ratio of the present invention comprises a main valve body 12 provided with inlet and outlet ports 21, 25, a pressure regulating chamber 26 is also provided on the top of the main valve body, and the end of the water inlet 21 is in the shape of a closed mouth, which communicates with the water inlet chamber 22 , the top of the water inlet chamber 22 leads to the pressure regulating chamber 26, the center of the bottom of the pressure regulating chamber 26 sinks into a small-diameter central chamber 23, the lower part of the central chamber is connected to the side water outlet chamber 24, and the end of the water outlet chamber 24 is trumpet-shaped Lead to water outlet 25.

[0018] The pressure regulating assembly is hermetically installed on the pressure regulating chamber 26 and fixed on the main valve body 12 through the screw rod 7 . The pressure regulating assembly includes a valve sleeve 6 and an elastic push block ...

Embodiment 2

[0021] Refer to Figure 4. Between the water inlet chamber 22 and the central chamber 23 of the main valve body, a pinhole channel 27 is provided. When the working pressure of the RO pure water machine is normal, the concentrated water discharged from the RO membrane tube first passes through the pinhole channel 27; when there is an abnormality in the water network at the work site, the working pressure of the RO pure water machine is too high, and the pressure of the RO membrane tube is too high , the pressure limiting device of the present invention also plays the role of pressure limiting and pressure relief, and the increase of pinhole channels can effectively increase the flow rate of concentrated water, so that the present invention can be applied to various medium and large pure water equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com