Automatic wood board feeding stock bin

A technology of automatic feeding and silo, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of waste cutting waste, high rework rate, not neat enough, etc., to reduce cutting waste. The effect of producing, reducing the cutting process, and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

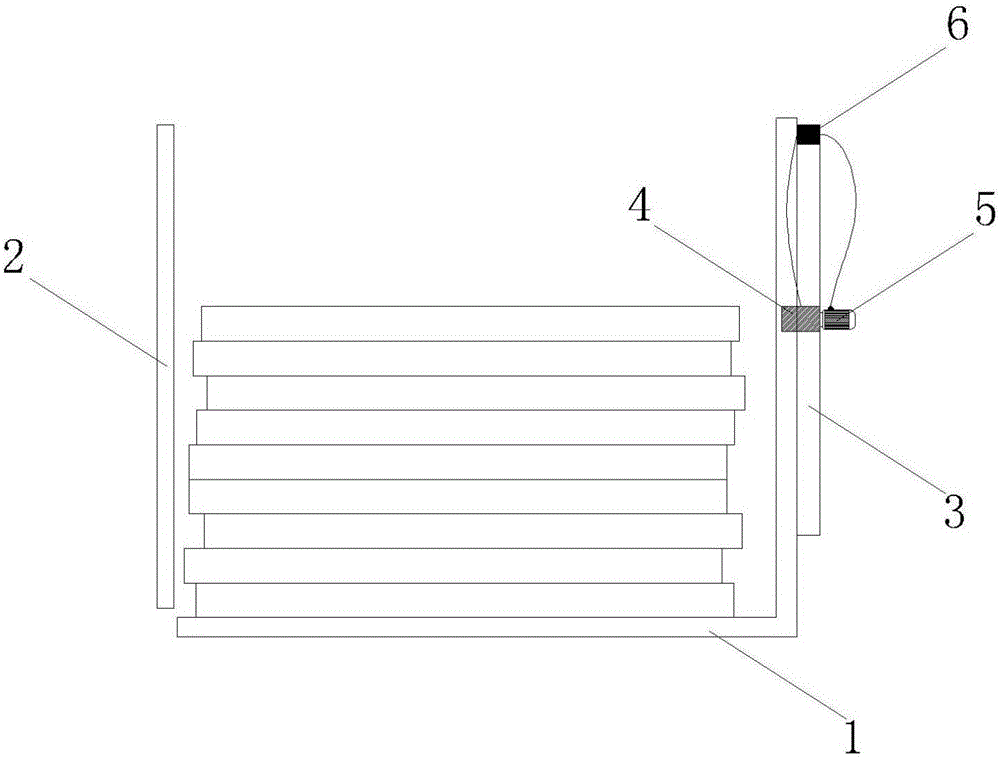

[0008] see figure 1 , the specific embodiment of the present invention adopts the following technical scheme: it comprises hopper 1, baffle plate 2, one side and upper opening of described hopper 1, side opening is provided with baffle plate 2, and baffle plate 2 can be forward and backward in the groove Move, the opposite side of the baffle plate 2 is provided with a vertical slide rail 3 on one end of the wall of the trough 1, and the slide rail 3 is provided with an infrared detector 4, and the infrared detector 4 can be placed on the slide rail 3 by a stepping motor 5. Walking up and down, the stepping motor 5 and the infrared detector 4 are electrically connected with the microprocessor 6 .

[0009] When stacking wooden boards, the machine puts the wooden boards one by one into the trough, and the infrared detector will detect whether there are wooden boards at the current height. If not, continue to place the wooden boards. If there are, the signal will be transmitted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com