Automatic threading device

A technology for threading and threading materials, used in transportation and packaging, winding strips, sending objects, etc., can solve the problems of low production efficiency, scrapped and broken substrates, etc., so as to reduce the problem of substrate rupture and improve material penetration The effect of efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

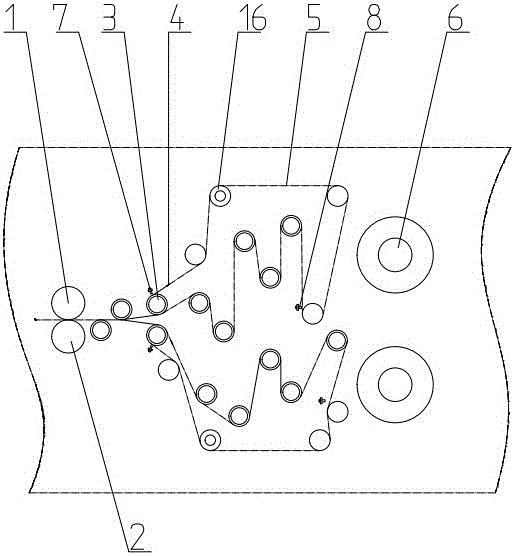

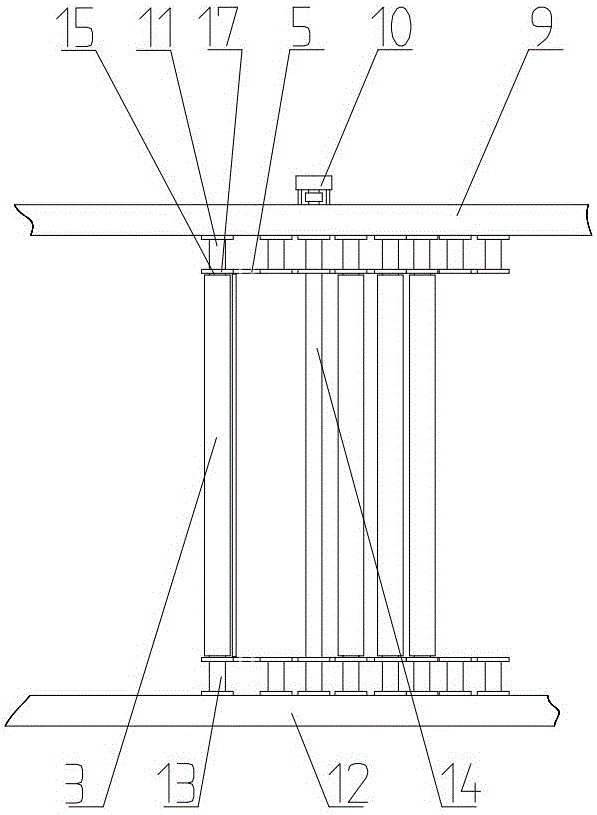

[0018] An upper slitting mechanism 1 and a lower slitting mechanism 2 are installed between the inner support plate 9 and the outer support plate 12, a number of inner mounting seats 11 are fixed at the side ends of the inner support plate 9, and some outer mounting seats 11 are fixed at the side ends of the outer support plate 12. Seat 13, supporting shaft 15 is supported inside the inner mounting base 11 and the outer mounting base 13, and the transmission roller 3 is rotatably mounted on the supporting shaft 15, wherein, after the upper slitting mechanism 1 and the lower slitting mechanism 2, there are two sets of belt transmission Mechanism, two sets of belt conveying mechanisms are set up and down, the substrate passes between the upper slitting mechanism 1 and the lower slitting mechanism 2 to be cut into multi-section substrates, part of the slit substrates is manually bonded On the upper side of the belt transmission mechanism, another part of the cut substrate is manua...

Embodiment 2

[0022] The difference with embodiment 1 is that the present embodiment replaces the driving sprocket in embodiment 1 with a driving pulley, replaces the driven sprocket in embodiment 1 with a driven pulley, and replaces the conveying chain in embodiment 1 with a conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com