Timing backwash sterilization purification water purification machine

A water purifier and backwashing technology, which is applied in the direction of reverse osmosis, biocide, semi-permeable membrane separation, etc., can solve the problems of high cost, increased product volume, cumbersomeness, etc., achieve constant water pressure and avoid product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] To make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

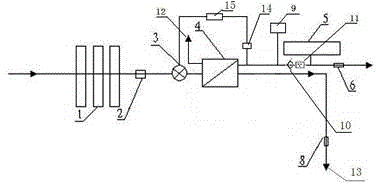

[0016] figure 1 It is the structure diagram of the reverse flushing osmosis water purifier of the present invention, which includes: water inlet pipe, combined filter element (PP filter element, granular activated carbon filter element, compressible carbon filter element), RO reverse osmosis membrane, pressure display device, water outlet pipe, return water pipe, Storage bucket 5. The upper part of the combined filter element is sequentially connected by a water pipe, and the PP filter element, the granular activated carbon filter element and the compressible carbon filter element are sequentially installed in the PP filter element, the granular activated carbon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com