Track board and prefabricating method thereof

A technology of track slabs and rail bearing platforms, applied in the field of track slabs and their prefabrication, can solve problems such as poor tension synchronization rate, cracks on the surface of track slabs, and slow growth of concrete strength, so as to achieve durability, train running safety, and prevent The effect of track slab separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

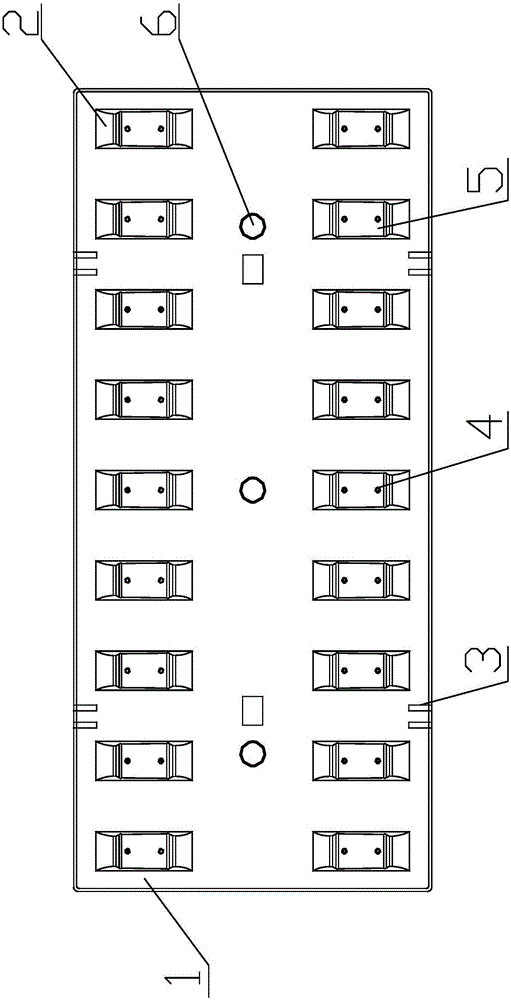

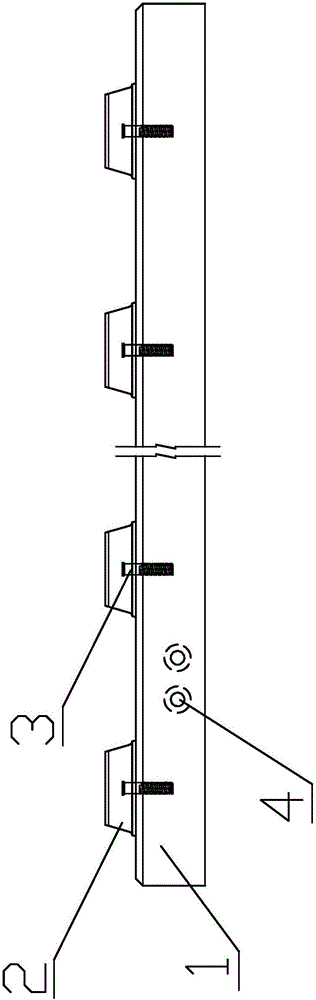

[0025] Such as figure 1 As shown, a track slab includes a track slab main body 1 and several rail-supporting platform shoulders 2 evenly arranged on the track slab main body 1. The track slab main body 1 is a bidirectional pretensioned prestressed reinforced concrete structure, and the track slab The main body 1 is provided with a reinforced mesh sheet, and several rail platform shoulders 2 are arranged symmetrically on the track plate main body 1. A rail bearing groove is opened on the rail platform shoulder 2, and a rail platform 5 is laid in the rail groove. Two rows of U-shaped steel bars are arranged symmetrically below the slab main body 1, and the U-shaped connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com