Correction system and method for ballastless track bridge of high speed railway run in soft soil area

A high-speed railway and ballastless track technology, applied in the field of deviation correction system, can solve the problems of high risk, large ballastless track structure damage, short skylight time, etc., to achieve flexible and controllable operation, controllable construction quality, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

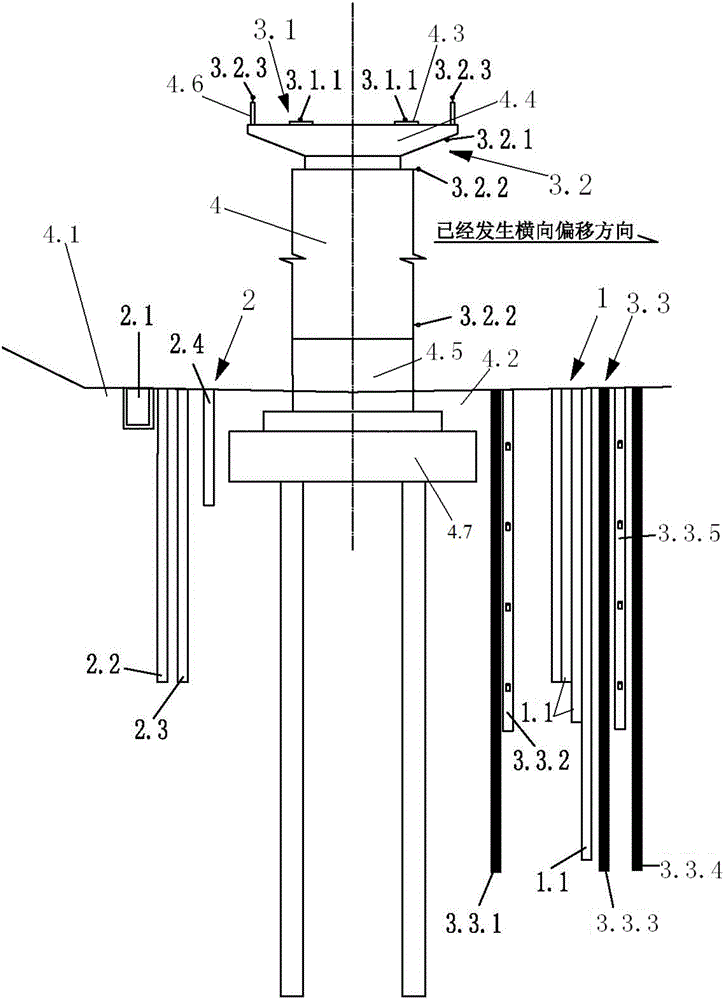

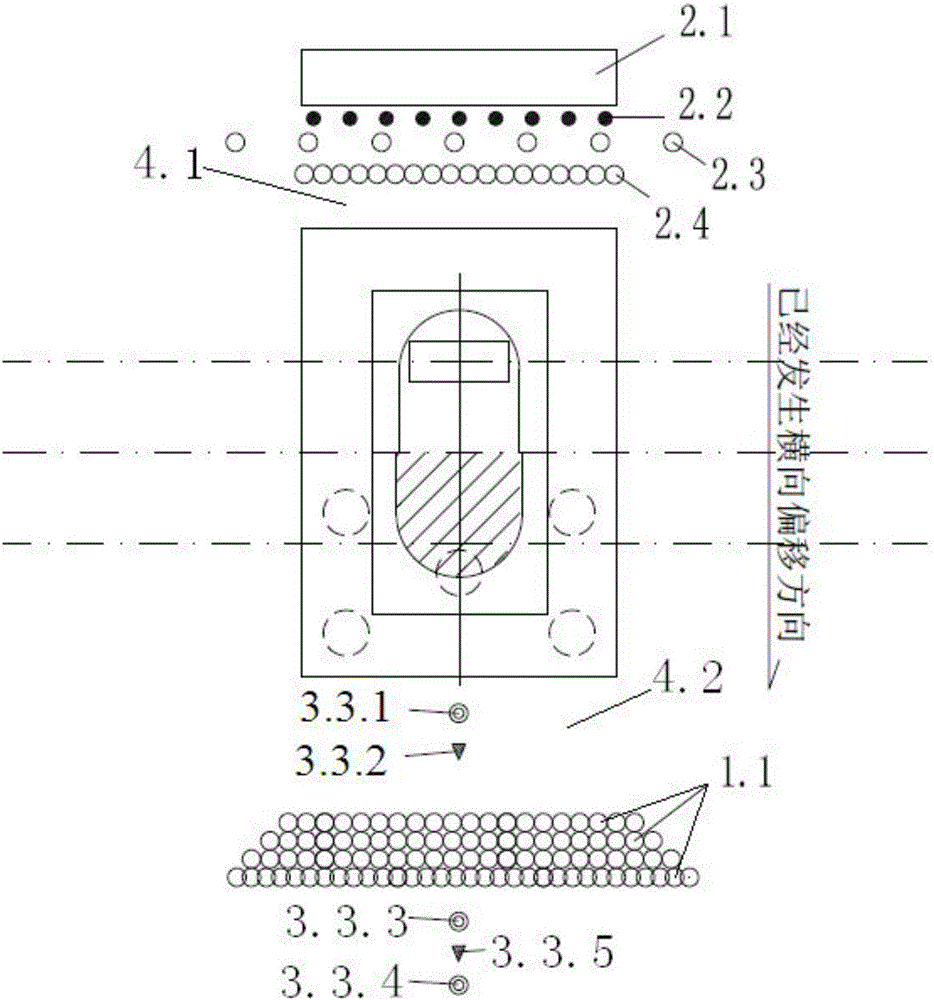

[0021] like figure 1 and figure 2 The described deviation correction system for operating high-speed railway ballastless track bridges in soft soil areas includes a force transmission system 1, a stress relief and release system 2 and a foundation deformation monitoring system 3.3. The force transmission system 1 includes multiple rows of high-pressure orientation Injection device 1.1, stress relief and release system 2 includes deformation groove 2.1, soil excavation hole group, stress relief hole group and stress relief hole group, foundation deformation monitoring system 3.3 includes first inclinometer pipe 3.3.1, second inclinometer pipe 3.3.3, the third inclinometer pipe 3.3.4, the first pore water pressure gauge 3.3.2 and the second pore water pressure gauge 3.3.5, among which, the lateral displacement of the high-speed railwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com