Combined-type clamping device used for clamping drill rod of underground drill rig

A tunnel drilling rig and combined technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of complicated operation, low degree of automation, small holding force, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

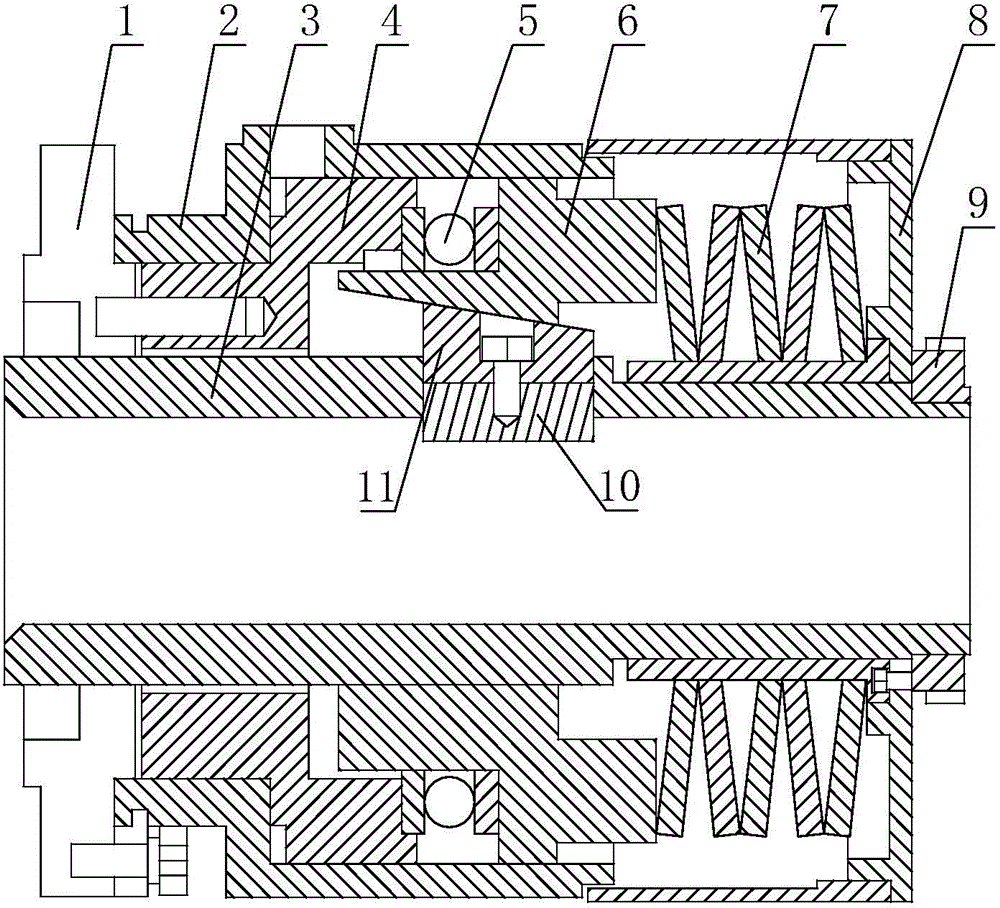

[0020] Such as figure 1 The shown combined clamping device for drilling rods of a tunnel drilling rig includes a socket sleeve 3 for fork-mounting drill rods, an outer baffle 1 and an inner baffle 4 that act as limit supports, and also includes a The slips 10 clamped to the drill pipe, the inner bevel drive block 11 for driving the slips 10 to move downward, and the outer bevel drive sleeve 6 matched with the inner bevel drive block 11; the left end of the socket 3 An outer baffle 1 and an inner baffle 4 are fixedly installed on the outer side in sequence, a protective shell 2 is arranged on the outer side of the inner baffle 4, the slip 10 is slidably installed in the middle of the socket sleeve 3, and the upper end of the slip 10 is It is fixedly connected with the lower end of the inner bevel driving block 11, and the outer bevel driving sleeve 6 is slidably arranged on the outside of the inner bevel driving block 11, and the outer bevel driving sleeve 6 and the inner baffl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com