Horizontal blade wind power generator

A technology of wind generators and horizontal wings, which is applied to the control of wind engines, wind motor combinations, and wind engines, etc., and can solve problems such as failure to make full use of wind farm resources, aggravate wind turbine vibration, and increase wind turbine costs , to improve the start-up performance and wind energy utilization, reduce the start-up wind speed, and increase the windward area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

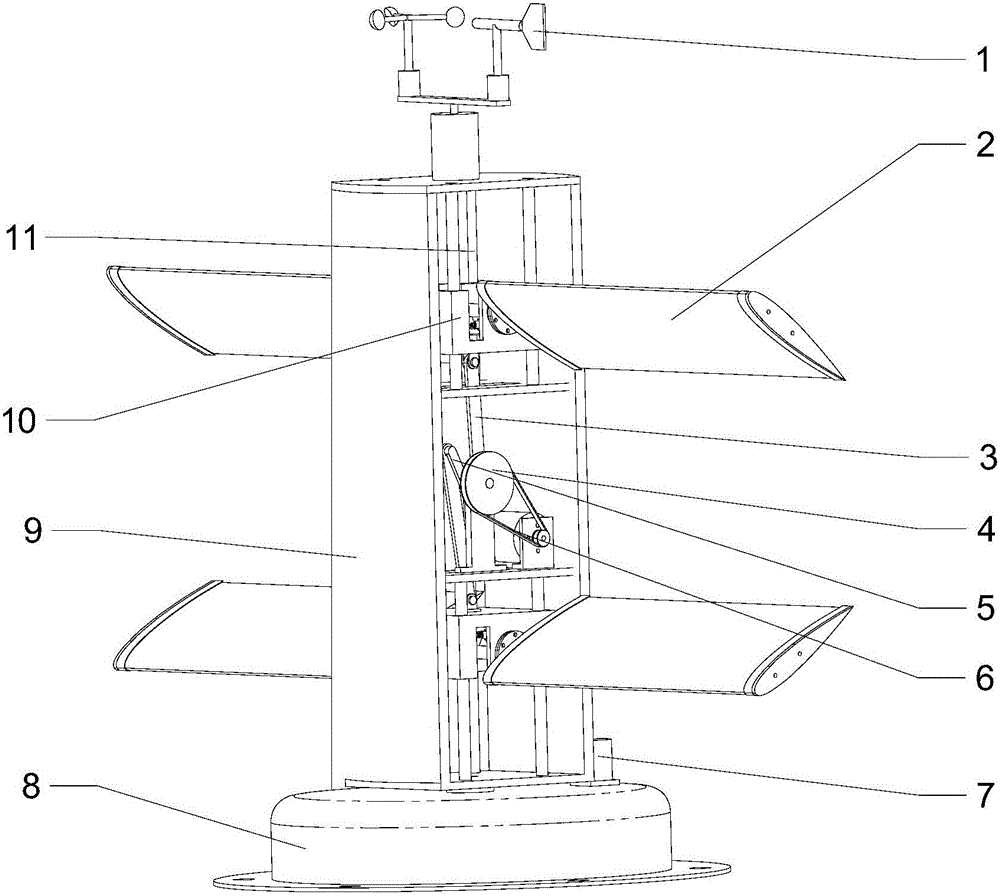

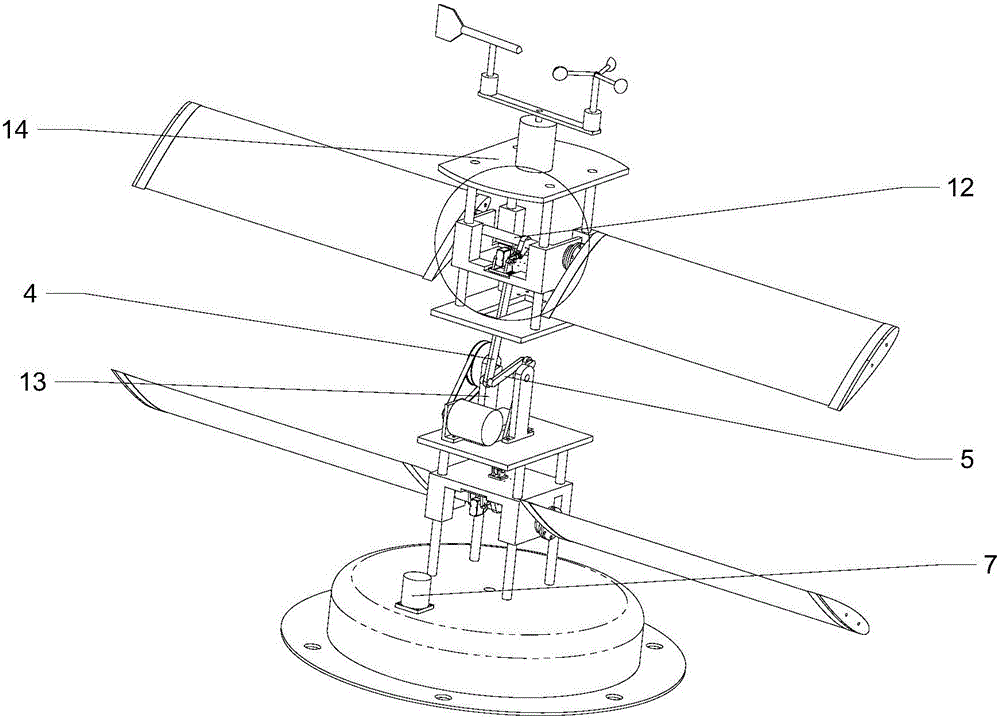

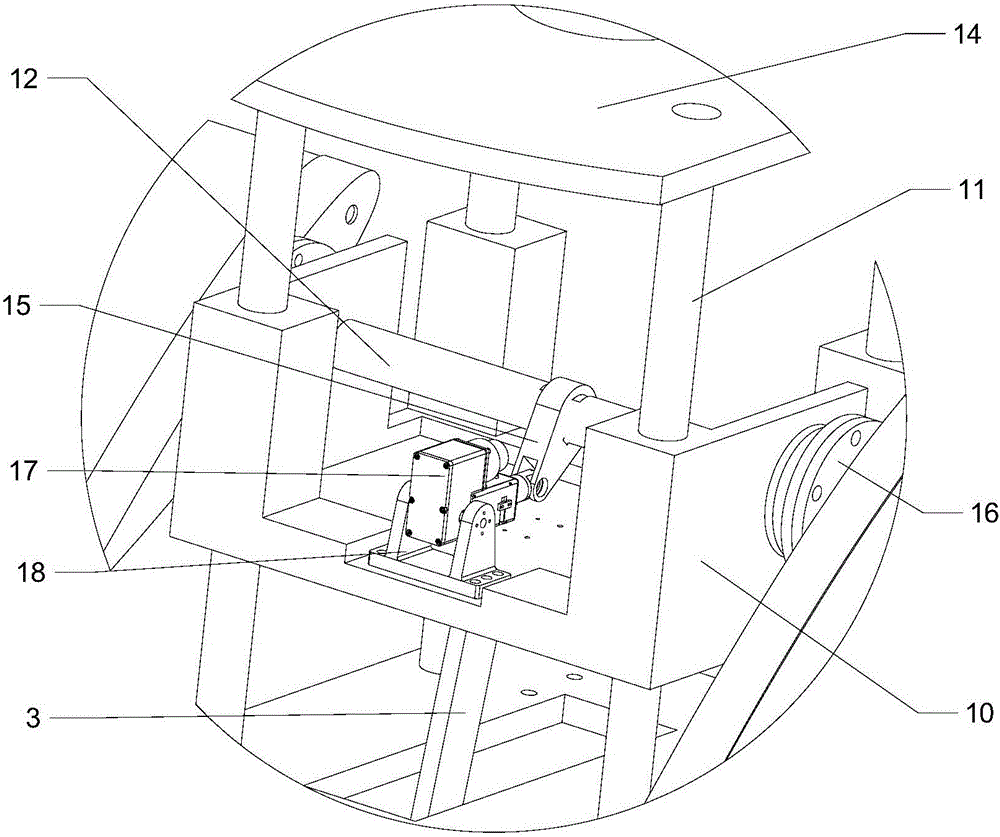

[0021] combine Figure 1~5 , the present invention is a horizontal wing wind generator, which is composed of two sets of blade mechanisms, a power generation module, a rotary module and a frame. Every group of vane mechanism comprises two vanes 2 and vane connecting rod 12 thereof, an electric cylinder 17 and base 18 thereof, large sliding seat 10, upper seat 11, cam 15, hinge seat 22 and guide rod 3 etc. are formed. Power generation module is made up of crankshaft 5, the synchronous belt speed-up mechanism that big and small pulleys and belt form and generator 24. The rotary module is composed of a detection wind force wind direction sensor 1 installed on the upper cover, a rotary motor 7 installed on the base and a synchronous belt deceleration mechanism composed of large and small pulleys. Frame comprises column 9, base 8 and loam cake 14 etc. are formed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com