Comprehensive self-cooled shaft seal system

A shaft sealing system, self-cooling technology, used in gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve problems such as poor results, reduce heat generation, save production costs and social resources, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to facilitate a better understanding of the content of the present invention, the present invention will be described in detail below in conjunction with the drawings. Since this embodiment is only an optimal embodiment and not the only way to achieve it, the present invention should protect the invention including this embodiment. widest range.

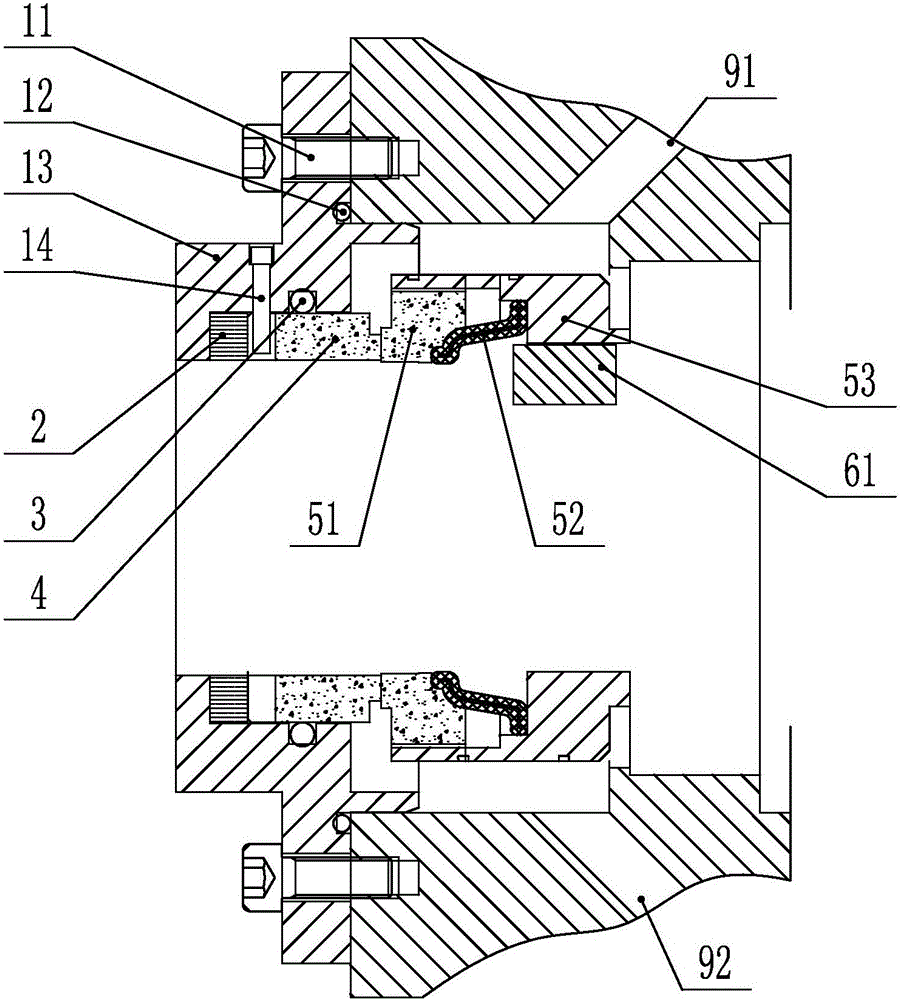

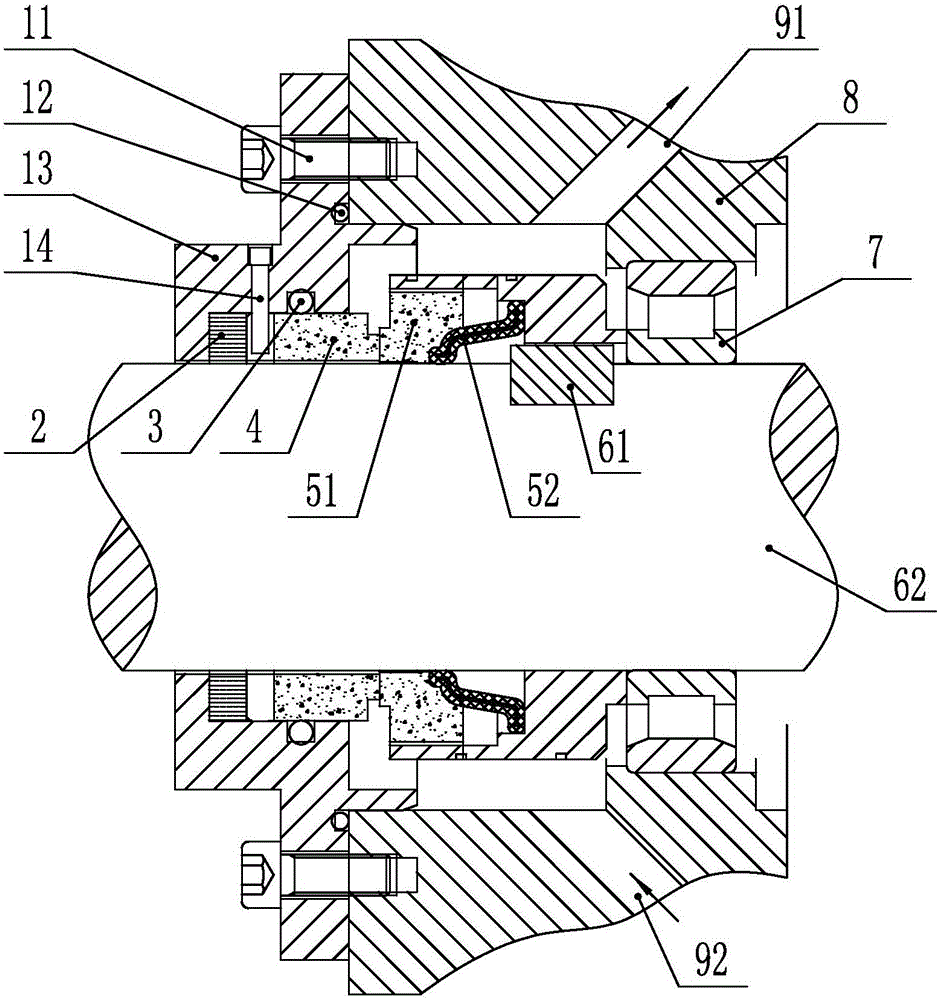

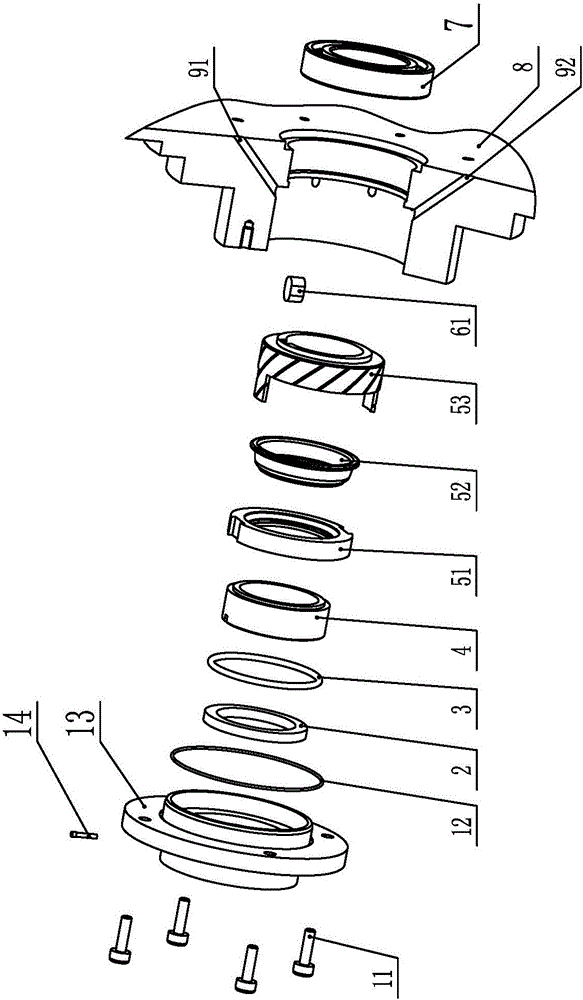

[0068] Such as figure 1 , 2 As shown in , 3, the present invention discloses a comprehensive self-cooling shaft seal system, which is applied to the shaft seal of the reducer. It is installed at the joint between the reducer shaft 62 and the chassis 8, and plays the role of sealing liquid. The system includes an end cover fixing assembly, a heat conduction and cooling ring 2 , a stationary auxiliary sealing ring 3 , a static liquid sealing friction ring 4 , a rotating liquid sealing assembly and a transmission key 61 on a crankshaft 62 . The rotary liquid seal assembly includes a rotary liquid seal friction ring 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com