Novel steel wire mesh framework plastic composite pipe

A steel mesh and composite pipe technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of poor tensile resistance at the connection position, and achieve the effects of excellent structure, low thermal conductivity, good connection strength and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

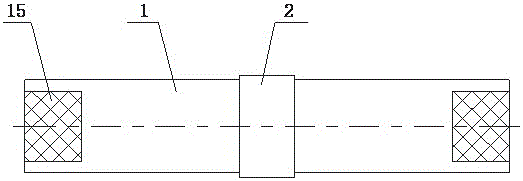

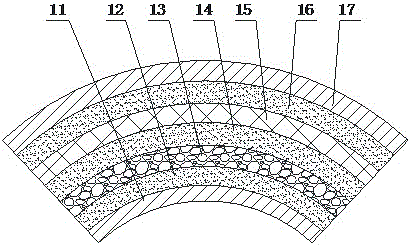

[0017] Such as figure 1 and figure 2 As shown, the present invention provides a new type of plastic composite pipe with steel mesh skeleton, which is formed by connecting several sections of composite pipe components 1 with each other through electric melting joints 2. And make it heated, so that the inner surface of the connected pipe fittings and the outer surface of the pipe are melted respectively, and the purpose of welding is achieved after cooling to the required time. The connection strength and sealing effect of the electric fusion connection are very good. The pipe material has strong axial tensile resistance; each composite pipe assembly 1 is formed by covering each other with an inner plastic pipe 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com